Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

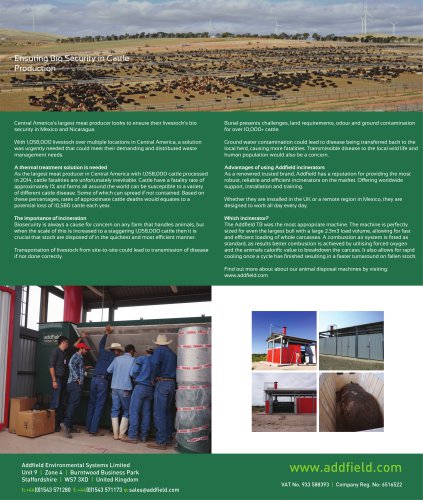

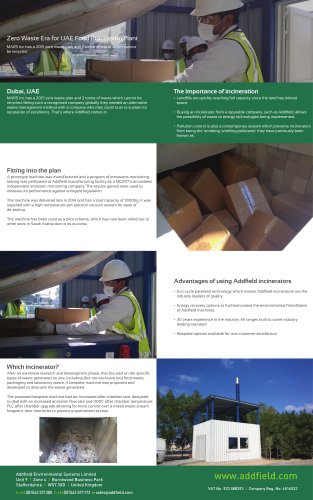

Ensuring Bio Security in Cattle Production Central America’s largest meat producer looks to ensure their livestock’s bio security in Mexico and Nicaragua. Burial presents challenges, land requirements, odour and ground contamination for over 10,000+ cattle. With 1,058,000 livestock over multiple locations in Central America, a solution was urgently needed that could meet their demanding and distributed waste management needs. Ground water contamination could lead to disease being transferred back to the local herd, causing more fatalities. Transmissible disease to the local wild life and human population would also be a concern. A thermal treatment solution is needed As the largest meat producer in Central America with 1,058,000 cattle processed in 2014, cattle fatalities are unfortunately inevitable. Cattle have a fatality rate of approximately 1% and farms all around the world can be susceptible to a variety of different cattle disease. Some of which can spread if not contained. Based on these percentages, rates of approximate cattle deaths would equates to a potential loss of 10,580 cattle each year. Advantages of using Addfield incinerators As a renowned trusted brand, Addfield has a reputation for providing the most robust, reliable and efficient incinerators on the market. Offering worldwide support, installation and training. The importance of incineration Biosecurity is always a cause for concern on any farm that handles animals, but when the scale of this is increased to a staggering 1,058,000 cattle then it is crucial that stock are disposed of in the quickest and most efficient manner. Which incinerator? The Addfield TB was the most appropriate machine. The machine is perfectly sized for even the largest bull with a large 2.3m3 load volume, allowing for fast and efficient loading of whole carcasses. A combustion air system is fitted as standard, as results better combustion is achieved by utilising forced oxygen and the animals calorific value to breakdown the carcass. It also allows for rapid cooling once a cycle has finished resulting in a faster turnaround on fallen stock. Transportation of livestock from site-to-site could lead to transmission of disease if not done correctly. Whether they are installed in the UK or a remote region in Mexico, they are designed to work all day every day. Find out more about about our animal disposal machines by visiting: www.addfield.com Addfield Environmental Systems Limited Unit 9 | Zone 4 | Burntwood Business Park Staffordshire | WS7 3XD | United Kingdom t: +44(0)1543 571280 f: +44(0)1543 571173 e: sales@addfield.com

Open the catalog to page 1All Addfield Environmental Systems catalogs and technical brochures

-

RAPID1000

4 Pages

-

MINI AB

3 Pages

-

MINI

3 Pages

-

MINI PLUS

3 Pages

-

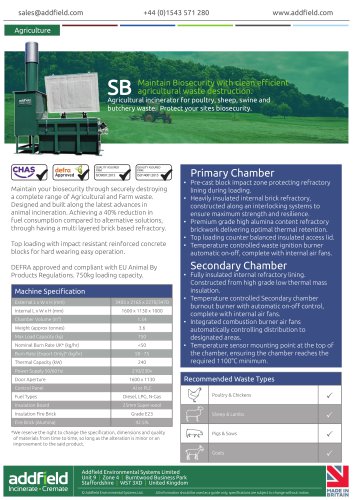

SB

3 Pages

-

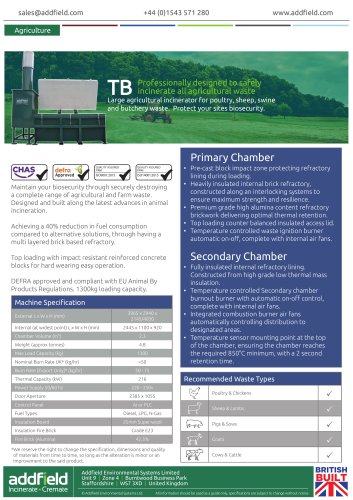

TB

3 Pages

-

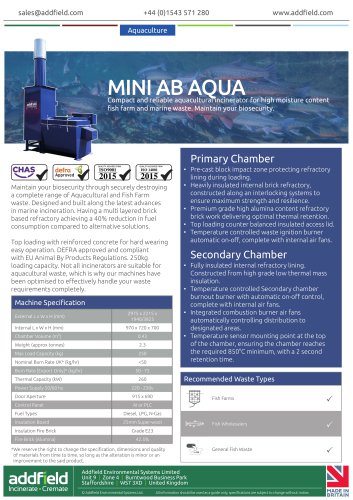

MINI AB AQUA

4 Pages

-

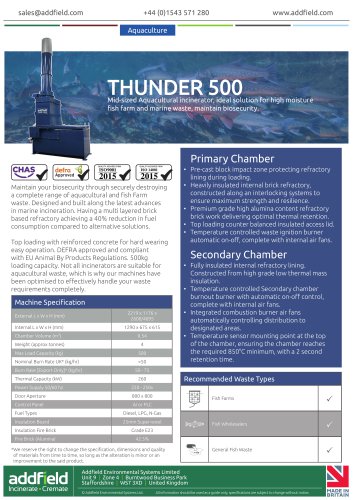

THUNDER 500

3 Pages

-

MP-500

3 Pages

-

Large Incineration Solutions

8 Pages

-

GM350

5 Pages

-

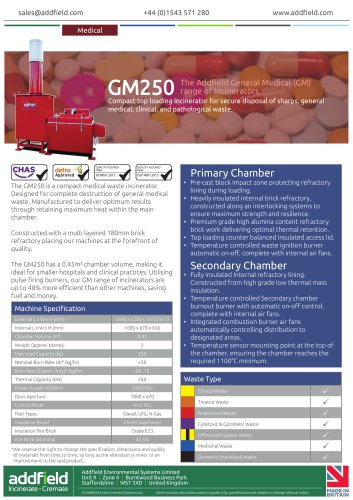

GM250

5 Pages

-

TB-AB PET

3 Pages

-

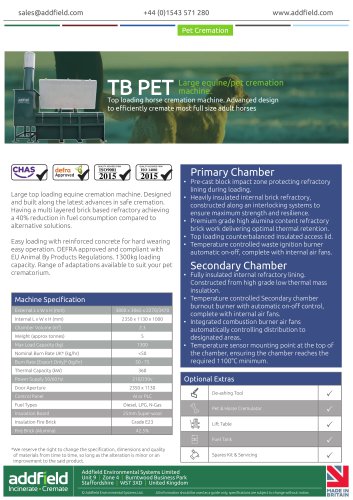

TB PET

3 Pages

-

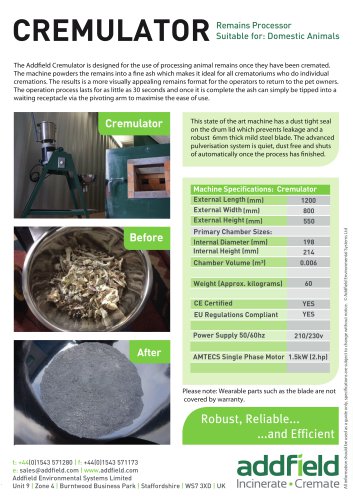

CREMULATOR

2 Pages

-

A50-IC (2)

3 Pages

-

AES100-2SEC

5 Pages

-

SKID MOUNTED RANGE

1 Pages

-

TRAILER MOUNTED AES RANGE

1 Pages

-

LABMASTER 25

4 Pages

-

RAPID1000

6 Pages

-

TBAB-MAX

5 Pages

-

C300

5 Pages

-

PetCremation

6 Pages

-

MP-100

8 Pages

-

Incinerate.Cremate

8 Pages

-

Lambing Season Case Study

1 Pages

-

Ascension Islands Case Study

2 Pages

-

SB - Animal Incinerator

5 Pages

-

Mini AB - Animal Incinerator

5 Pages