Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

Zero Waste Era for UAE Food Processing Plant MARS Inc has a 2015 zero waste plan and 2 tonne of waste which cannot be recycled. MARS Inc has a 2015 zero waste plan and 2 tonne of waste which cannot be recycled. Being such a recognised company globally they needed an alternative waste management method with a company who they could trust to sustain its reputation of excellence. That’s where Addfield comes in. • Landfills are quickly reaching full capacity since the land has limited space. • Buying an incinerator from a reputable company, such as Addfield, allows the possibility of waste to energy technologies being implemented. • Pollution control is also a contemporary system which prevents incinerators from being the ‘smoking, smelling pollutants’ they have previously been known as. Fitting into the plan A prototype machine was manufactured and a program of emissions monitoring testing was performed at Addfield manufacturing facility by a MCERT’s accredited, independent emission monitoring company. The results gained were used to measure its performance against stringent legislation. The machine was delivered late in 2014 and has a load capacity of 1000kg. It was supplied with a high temperature ash ejection vacuum system for ease of de-ashing. The machine has been used as a pilot scheme, which has now been rolled out to other sites in Saudi Arabia due to its success. Advantages of using Addfield incinerators • Eco-cycle patented technology which means Addfield incinerators are the industry leaders of quality • Energy recovery options to furtherincrease the environmental friendliness of Addfield machines. • 30 years experience in the industry All ranges built to same industry leading standard • Bespoke options available for true customer satisfaction Which incinerator? After an extensive research and development phase, that focused on the specific types of waste generated on site, including (but not exclusive too) food waste, packaging and laboratory waste. A bespoke machine was proposed and developed to deal with the waste generated. The proposed bespoke machine had an: Increased after chamber size, designed to deal with an increased emission flow rate and 1100C after chamber temperature. PLC after chamber upgrade allowing for more control over a mixed waste stream Magnetic door interlocks to prevent unauthorised access. Addfield Environmental Systems Limited Unit 9 | Zone 4 | Burntwood Business Park Staffordshire | WS7 3XD | United Kingdom t: +44(0)1543 571280 f: +44(0)1543 571173 e: sales@addfield.com

Open the catalog to page 1All Addfield Environmental Systems catalogs and technical brochures

-

RAPID1000

4 Pages

-

MINI AB

3 Pages

-

MINI

3 Pages

-

MINI PLUS

3 Pages

-

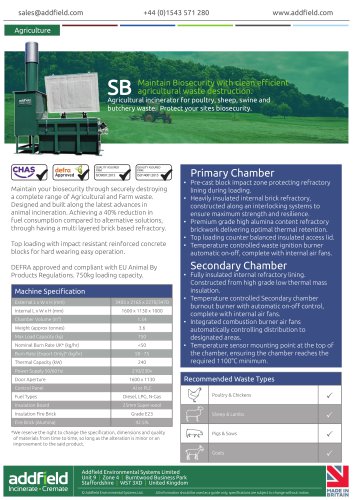

SB

3 Pages

-

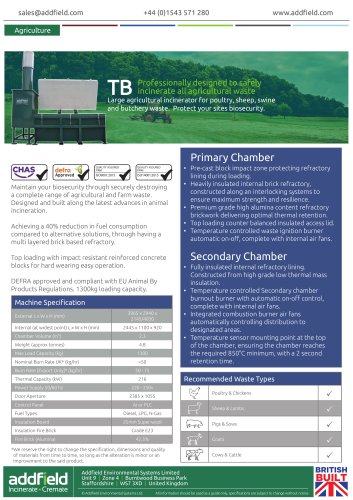

TB

3 Pages

-

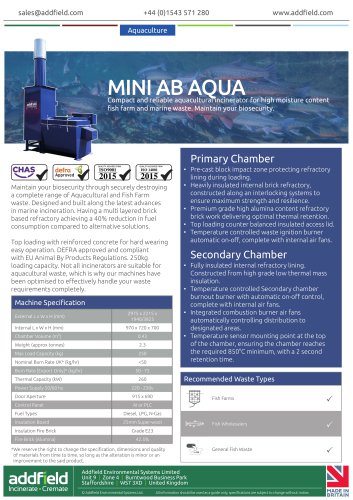

MINI AB AQUA

4 Pages

-

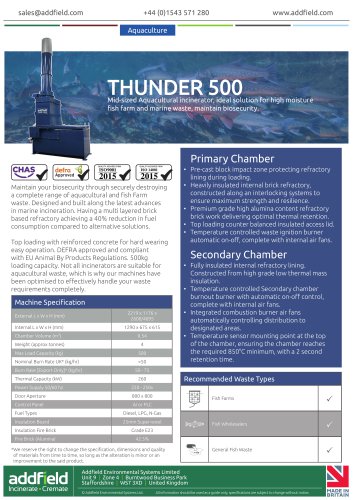

THUNDER 500

3 Pages

-

MP-500

3 Pages

-

Large Incineration Solutions

8 Pages

-

GM350

5 Pages

-

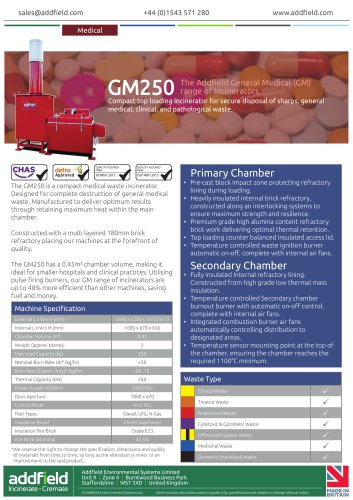

GM250

5 Pages

-

TB-AB PET

3 Pages

-

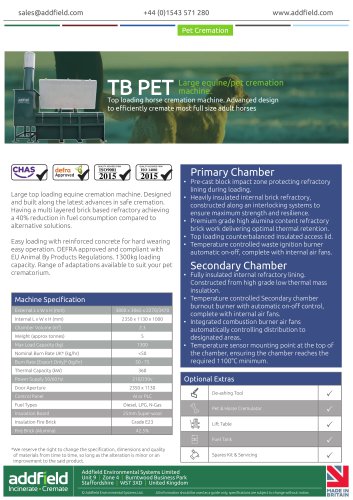

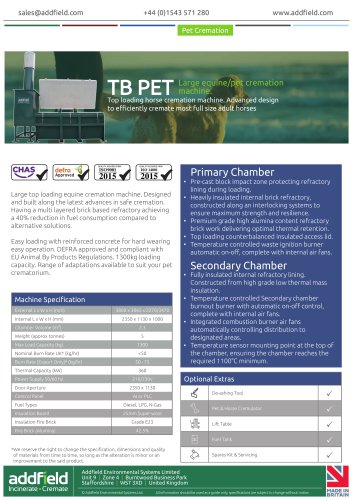

TB PET

3 Pages

-

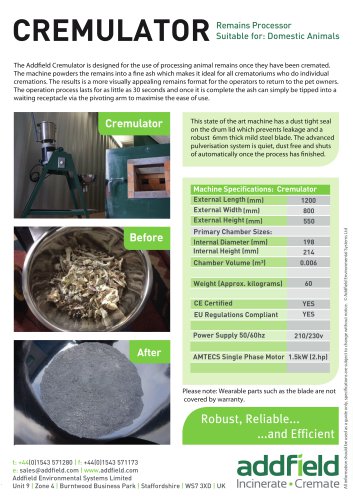

CREMULATOR

2 Pages

-

A50-IC (2)

3 Pages

-

AES100-2SEC

5 Pages

-

SKID MOUNTED RANGE

1 Pages

-

TRAILER MOUNTED AES RANGE

1 Pages

-

LABMASTER 25

4 Pages

-

RAPID1000

6 Pages

-

TBAB-MAX

5 Pages

-

C300

5 Pages

-

PetCremation

6 Pages

-

MP-100

8 Pages

-

Incinerate.Cremate

8 Pages

-

Lambing Season Case Study

1 Pages

-

Ascension Islands Case Study

2 Pages

-

SB - Animal Incinerator

5 Pages

-

Mini AB - Animal Incinerator

5 Pages