Website:

Group Schumacher

Website:

Group Schumacher

Catalog excerpts

The only universal cutting system on the market higher workrates Easy, bolt-on assembly Exceptional strength Excellent cutting quality wider harvest windows Combine harvesting demands peak performance. Use the best equipment as you take to the field. The cutting system is the key to your success 2 User benefits quieter machine running ̈ Reduced replacement costs ̈ Reduced changeover and down times ̈ Country-wide availability of parts

Open the catalog to page 2

EasyCut II the modular cutting system When the guards wear When the sections wear When the wear plates wear Precise and clean cuts for boosted outputs crop lifter cutting system

Open the catalog to page 3

Box shaped design The guards are bolted to the top and the bottom of the angle bar for maximum stability and height control Wear plates at the back ensure perfect adjustment and firm attachment Two cutting edges High wear-resistant surfaces and a flexible core The Schumacher guard has two cutting edges that provide effective guidance to the knife. Beveled cutting edges are hardened for extra sharpness and resistance to wear Precision gaps give smooth knife co

Open the catalog to page 4

Self-cleaning ProCut sections are hardened throughout and their surfaces are galvanized The teeth are optimized to suit all harvest conditions Configuration option ProCut Standard / ProCut air ProCut Standard The sections are fitted in the unique Schumacher face-up/face-down. Tight fit The bolts that are used to attach the ProCut sections have serrated and conical shafts for firm attachment to the knife At the same time they make for easy replacement of the sec

Open the catalog to page 5

The EasyCut II sectional knife Easy shipping All knives fit in a 2.60m (9ft) box Easy shipping Prompt and cost-effective next-day delivery Knife assembly kit Easy transport, storage and assembly Easy assembly Precote bolts ensure tight fit 11

Open the catalog to page 6

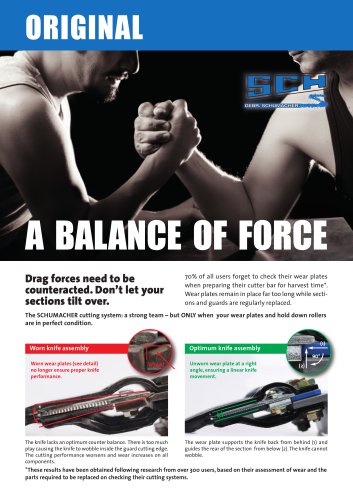

The EasyCut II wear plate The wear plate supports the knife back and guides the section Individual component that is easy to replace Forces need to be countered, otherwise the cut gets out of control.

Open the catalog to page 7

The EasyCut II roller guide The box principle Ball bearings in roller guides ensure smooth knife performance Zero maintenance Keeps the knife level as it moves under load through the gap COUNTER FORCE pressure disc The roller holds down the section as the pressure disc rotates without friction. Optimal guidance for the knife 14 DRAG FORCE roller guide guard knife back wear plate

Open the catalog to page 8

Guards + 1 spare guard Knife incl. knife connection kits Knife head and accessories Knife guidance Standard: Wear plates Comfort: Wear plates and top rollers Premium: Top and bottom rollers, spacers Each kit has all the parts and adapters that are necessary for my specific model and width. My EasyCut cutting system 16 Bobbins to accommodate the lifters Bolts and nuts Spare replacement sections Assembly instructions and parts li

Open the catalog to page 9

Wear plates İ System of wear plates and hold-down rollers Suits all popular headers A clean cut - meter after meter Top and bottom rollers, spacers Suits a limited number of headers

Open the catalog to page 10

EasyCut II spare parts Double guard Triple guard First guard The -X- dimension Original spare parts shipped in original boxes Maintain the cutting force 20 Please note that the -X- dimension is a crucial parameter in choosing the correct guard version (12|14|17mm) and correct wear plate (4|5|6mm). wear plate

Open the catalog to page 11

EasyCut II spare parts ProCut sections fine 14 tpi = 14 teeth per inch Type coarse 11 tpi = 11 teeth per inch Bottom roller Wear plates Fine sections Dimension Color

Open the catalog to page 12

When the guards wear Guards need regular checks for wear A new guard offers a 3.8 - 4.2mm gap when installed to the cutterbar The MultiTool is easy to use and the ideal helper for every combine operator. In a gap wider than 5.4mm there is no control on the knife. The rounded cutting edges are unable to catch and cut the stems properly

Open the catalog to page 13

When the sections wear The teeth are pointed The space between the teeth is worn. This section will not give clean cuts The pointed teeth seem sharp but are not The stems are not cut but pronged. This way they are pulled into the guard as the section changes direction Take a new section and use it as template. Bolt the worn section to it for comparison and determine the degree of wear. This leads to blockages, higher input power and vibration Measuring section wear 26

Open the catalog to page 14

When the wear plates wear Worn wear plates The 90° edge is worn Lacking proper control and guidance, the section wobbles as it moves in the gap WEAR The knife has lost optimum counter balance. There is too much play causing the knife to wobble inside the guard Worn wear plates affect the performance of the knife. Replace the wear plates 28 The cut becomes less precise and wear increases on all components involv

Open the catalog to page 15

Perfect Harvest App How2 VIDEO App A useful tool that keeps your cutting system and cutterbar in good shape. Detect wear and save fuel 30 Determine the degree of wear anytime, anywhere Fine-tune the cutterbar settings Replace worn parts properly Download the app and apply the tool: Take a photo of the worn section Determine the degree of wear Calculate the extra fuel consumption due to wear YouTube.com - GROUP SCHU

Open the catalog to page 16

Why using grain lifters? Use grain lifters – boost your productivity Advantages of grain lifters Lifters significantly reduce losses in down crop Lifters reduce overall machine wear, because no soil will enter the combine when cutting too low Grain lifters are exposed to great forces. ASL grain lifter – the genuine product 32 Lifters reduce cutter bar losses in short-stemmed grain and low-hanging ears Lifters significantly enhance the crop intake and threshing results by optimizing the materia

Open the catalog to page 17

ASL grain lifter kinked SlimProfile Features Security label Attached and height-adjusted without tools 20% less skid wear Excellent stability and gliding dynamics Reduced wear and optimized crop flow User benefits ̈ Reduced changeover and down times ̈ Much lower loss rate ̈ Reduced replacement

Open the catalog to page 18

Perfect Harvest.

Open the catalog to page 19All Group Schumacher catalogs and technical brochures

-

Hedge Trimmer

11 Pages

-

CROP LIFTER

13 Pages

-

Chopping TECHNOLOGY

7 Pages

-

SCHNITT punkt 2017-2018

12 Pages

-

Drive TECHNOLOGY

21 Pages

-

A balance of force

2 Pages

-

Cutting force

36 Pages