Katalogauszüge

Founded in 1954, Alapala Machine is the oldest and the most well-known company of the Alapala Group. It takes its place among the leading companies of the world in its sector, with a vision to be the leader.

Katalog auf Seite 4 öffnen

PASSION FOR MILLING SINCE 1954 Alapala Machine builds turnkey plants of any desired capacity and is one of the top 500 exporters in Turkey, exporting 95% of its production. It has a considerable number of turnkey references in more than 85 countries in all the 4 continents including developed and industrial countries such as Germany, France, Italy and U.S.A. It provides best pre-sales and after-sales services with its staff of highly specialized personel in the industry and strong overseas representation which includes strong service networks and spare-part stocks. Alapala manufactures high...

Katalog auf Seite 5 öffnen

milling section ROLLER MILL SIMILAGO II ROLLER MILL SIMILAGO ROLLER MILL AURORA PLANSIFTER QUADRO PLANSIFTER ARION PURIFIER PURIFIER VIBRO SIFTER 4 CONTROL PLANSIFTER BRAN FINISHER TURBO CONTROL SIFTER IMPACT DETACHER DRUM DETACHER VIBRO FEEDER INFESTATION DESTROYER FOR FLOUR SILO DISCHARGER

Katalog auf Seite 6 öffnen

MILLING SECTION

Katalog auf Seite 7 öffnen

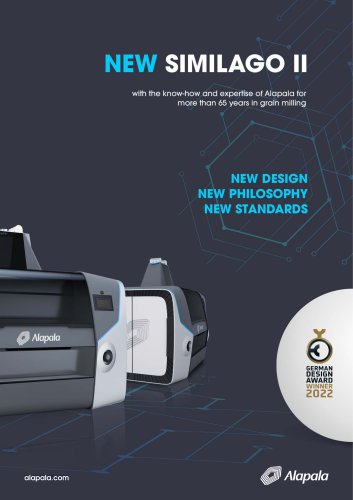

New Generation ROLLER MILL SIMILAGO II SCOPE OF USE SIMILAGO II Roller Mill, which has joined Alapala family, is used for milling grains to produce flour by conveying the grain through cylindrical rolls.

Katalog auf Seite 8 öffnen

APPLICATION FIELDS At food industry Flour and semolina plants Other food processing plants INNOVATIONS Operationally, a feeder conveys the grains between a pair of rollers rotating at different speeds, with ground or threaded surfaces depending on the purpose of use, and these rollers mill the grains. Structurally, the roller mill has a sturdy structure with excellent features, designed to obtain maximum efficiency and to maintain its position at every stage of the milling process. The internal parts of SIMILAGO II, where the product does not contact directly but may adhere on the surfaces...

Katalog auf Seite 9 öffnen

ROLLER MILL SIMILAGO II

Katalog auf Seite 10 öffnen

the world was waiting for. All product contact parts in stainless steel Easy-to-remove assembly Single high and double high models Accurate roll positioning Optional roll adjustment automation Special software solutions, graphical and touch-screen Roll replacement within 20 minutes Next Generation roller mill. The versatility & power you can always count on.

Katalog auf Seite 11 öffnen

ROLLER MILL SIMILAGO II PRODUCT INLET PRODUCT INLET MATERIAL INLET LEVEL SWITCHES SHUT-OFF VALVE øJ FINE ADJUSTMENT GROUP FEED ROLLS GRINDIG ROLLS ASPIRATION CHANNEL MATERIAL OUTLET AIR SUCKING BREAK PASSAGES REDUCTION PASSAGES DAVS II 4 x ø 250 / 800 DAVS II 4 x ø 250 / 1000 DAVS II 4 x ø 250 / 1250 DAVS II 8 x ø 250 / 800 DAVS II 8 x ø 250 / 1000 DAVS II 8 x ø 250 / 1250 DAVS II 4 x ø 300 / 1250 DAVS II 8 x ø 300 / 1250

Katalog auf Seite 12 öffnen

ROLLER MILL DAVS SIMILAGO SCOPE OF USE Similago Roller Mill, which has joined Alapala family under the model name DAVS, is used for milling grains to produce flour by conveying the grain through cylindrical rolls.

Katalog auf Seite 14 öffnen

APPLICATION FIELDS At food industry Flour and semolina plants Other food processing plants INNOVATIONS Operationally, a feeder conveys the grains between a pair of rollers rotating at different speeds, with ground or threaded surfaces depending on the purpose of use, and these rollers mill the grains. Structurally, the roller mill has a sturdy structure with excellent features, designed to obtain maximum efficiency and to maintain its position at every stage of the milling process. The internal parts of DAVS, where the product does not contact directly but may adhere on the surfaces because...

Katalog auf Seite 15 öffnen

ROLLER MILL DAVS SIMILAGO PRODUCT INLET PRODUCT INLET MATERIAL INLET LEVEL SWITCHES SHUT-OFF VALVE FINE ADJUSTMENT GROUP FEED ROLLS ASPIRATION CHANNEL REDUCTION PASSAGES BREAK PASSAGES MATERIAL OUTLET AIR SUCKING

Katalog auf Seite 16 öffnen

ROLLER MILL DAVM SCOPE OF USE It is used to grind and crush the grain in the cereal processing plants. It is designed to obtain flour and semolina in the flour and semolina mills by processing cleaned grain.

Katalog auf Seite 18 öffnen

APPLICATION FIELDS At food industry Flour & semolina mills Corn, barley, rye and similar cereal processing plants At other food industries for rolling, crushing and other similar processes INNOVATIONS Our DAVM model of the roller mill is equipped with a belt system, which provides several advantages to the user compared to the geared type roller mill. Since gearbox is not used, consequently, there is no need to modify gears because their size get smaller in geared type roller mills due to calibration of the rolls. There is no need to inspect oil periodically. Periodic maintenance is...

Katalog auf Seite 19 öffnen

ROLLER MILL DAVM PRODUCT INLET PRODUCT INLET LEVEL SWITCHES SHUT-OFF VALVE FEED ROLLS FINE ADJUSTMENT GROUP GRINDIG ROLLS MATERIAL OUTLET AIR SUCKING BREAK PASSAGES REDUCTION PASSAGES Technical Features ASPIRATION CHANNEL

Katalog auf Seite 20 öffnen

New Generation QUADRO PLANSIFTER AURORA SCOPE OF USE The square sifter offers many advantages for sifting processes at high capacities. It provides large sifting area in very limited space. The maximum sifting area can be obtained by using different types of boxes. It is used to sift the broken and floury products and classify different kinds of grains. Modular plansifter There are differences in the new model modular plansifter in terms of production, hygiene and assembly-disassembly as well as increasable and reducible passage. Production Quick deadlines can be ensured in response to...

Katalog auf Seite 22 öffnen

STRUCTURE The machine is produced in three different types. Types are classified according to the size of sifting area and manufacture method. While DPAK has a normal sifting area, AURORA has a high sifting area. In addition, the model with assembly and disassembly facility is MODULAR AURORA. This machine consists of three main parts. Two sieve boxes and a central framework containing the drive unit. These parts are assembled by means of screws and transversal beams. It is possible to separate the machine into three main parts for an easy make handling, shipping and hoisting to the...

Katalog auf Seite 23 öffnenAlle Kataloge und technischen Broschüren von Alapala

-

SIMILAGO II

16 Seiten

-

AURORA MODULAR PLANSIFTER

16 Seiten

-

GRAIN STORAGE & HANDLING SYSTEMS

17 Seiten

-

NEW SIMILAGO II

12 Seiten