Katalogauszüge

Roll-Belt. Change your baling style. New Holland has led the Roll-Belt baler segment for over 25 years, and has introduced a string of pioneering firsts that have revolutionised the way variable chamber balers operate today. Over 275,000 Roll-Belt balers are working around the globe in the expert hands of farmers and contractors to bring the harvest home. The latest generation is set to redefine round baling with advanced Roll-Belt technology that can improve capacity by up to 20% and density by up to 5%. What’s more, operators can select between a 150cm or 180cm maximum bale size to suit...

Katalog auf Seite 2 öffnen

Version available IntelliBale™ technology for baling automation Four endless belts for baling efficiency In-cab density control system On-board automatic greasing system Wide opening single piece side shields Optional real time bale moisture sensing Productivity enhancing drop floor Smooth feeding roller windguard Choose from ActiveSweep™, SuperFeed™ or CropCutter™ p

Katalog auf Seite 3 öffnen

A long history of Roll-Belt baling from New Holland. New Holland invented modern baling over 70 years ago with the invention of the world’s very first self-tying pickup baler in 1940, and an unceasing quest for continual innovation was started. The very first round baler was launched 40 years ago back in 1974. Fast forward 15 years to 1989, and the first Roll-Belt baler was produced, the Model 630, and the rest, as they say, is history. Born in New Holland’s ancestral home and Centre of Round Baling Excellence in Pennsylvania, USA, today’s Roll-Belt balers have been designed and developed...

Katalog auf Seite 4 öffnen

1974: The very first round baler is developed, the Model 850 and uses chains to produce a 150cm bale. 1976: The range’s popularity leads to the introduction of the Model 845, which produces smaller, 120cm bales. 1978: The fast expanding range now features the Models 851 and 846. 1979: The Model 852 proves a hit with farmers. 1982: The most advanced chain baler to date is unleashed: the Model 849. 1989: The face of variable chamber baling changed forever with the introduction of the Model 630, the very first belt baler. 2002: The upgraded BR700 series is launched, and the all new BR740...

Katalog auf Seite 5 öffnen

The fastest way to clear fields. The pick-up is perhaps one of the most important parts of your Roll-Belt baler. New Holland has completely redesigned the 2.3 metre wide pick-up to boost capacity by up to 20%. If that wasn’t enough, state-of-the-art baling technology ensures uniform flow for non-stop, high capacity baling.

Katalog auf Seite 6 öffnen

Uniform crop flow Ultimate feeding performance • The standard roller windguard continually rotates to guarantee a smooth, even flow of crop into the baler to increase crop processing efficiency • Operators can regulate the height of the roller windguard to guarantee optimal flow into the baler • The feeding logic has been developed which is set to significantly improve baler efficiency • The system uses two contra rotating overshot and undershot augers to direct and merge the crop flow into the rotor • Feed assist roller positively directs the crop into the rotor to maintain a constant crop...

Katalog auf Seite 7 öffnen

Flexible crop processing solutions. What are your bales going to be used for? As no two baling operations are the same, the Roll-Belt baler offers different crop processing options to suit your individual requirements. The ActiveSweep™ system transfers the crop directly from the pick-up to the bale chamber for gentle handling. The SuperFeed™ option enables straight through processing, to maintain long unbroken straw. CropCutter™ models guarantee super fine chopping for the densest, most nutritious silage bales. No matter what the crop, growing conditions or usage profile, the Roll-Belt...

Katalog auf Seite 8 öffnen

SUPERFEED™ PROCESSING OPTION Long unbroken straw and hay thanks to the SuperFeed™ system • SuperFeed™ system guarantees even feeding performance • The ingenious design not only divides the power requirement equally over the two rotor halves, but also ensures an equal distribution of the crop • 15 rows of fingers, each with three tines, maintains optimal crop integrity ACTIVESWEEP™ PROCESSING OPTION ActiveSweep™ feeding system: ultimate baling simplicity • ActiveSweep™ feeding system has been designed for traditional hay and straw focused operations together with those which specialize in...

Katalog auf Seite 9 öffnen

The perfect bale for your operation. New Holland has perfected bale formation and its 275,000 Roll-Belt balers are testament to this success. The combination of both rollers and belts ensures that bales are perfectly formed with a dense core. Furthermore, even density across the entire bale makes them resistant to extensive handling and improves the fermentation profile of silage bales. The variable chamber technology means that operations can vary the size of the bale produced in 5cm increments, from 90cm right up to 150 or 180cm to enhance baling flexibility.

Katalog auf Seite 10 öffnen

The densest cores around • Initial bale density is determined by five formation rollers, of which three are pivoting, and form a natural ‘D’ shape to make the first roll • This shape has been proven, during extensive testing, to produce the densest bale core Endless belts for endless baling efficiency • The four new endless, 273mm wide belts, feature improved reliability and reduce crop losses • Constructed from advanced materials, the self-cleaning belts have been specifically engineered to maintain better contact with the crop, especially in short grasses • Uniform pressure is exerted for...

Katalog auf Seite 11 öffnen

Tailored wrapping options. Efficient wrapping is what makes a nice bale, instead of a mountain of material. The entire wrapping system has been upgraded, to speed up the process and to enhance accuracy to deliver best-in-class bale shape first time, every time. Second generation Duckbill system • Second generation Duckbill system is physically closer to the bale, speeding up the entire wrapping process • Spreader rolls maintain uniform coverage across the entire bale and the net wrap is actively placed inside the chamber, next to the bale for more accurate wrapping performance • The amount...

Katalog auf Seite 12 öffnenAlle Kataloge und technischen Broschüren von NEW HOLLAND

-

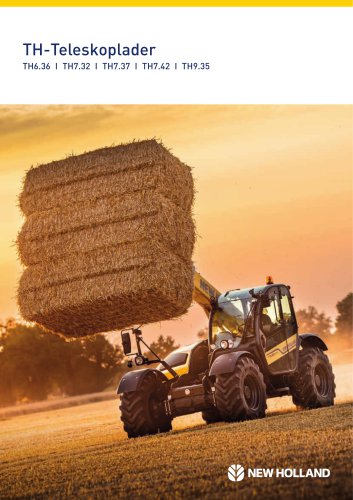

TH-BAUREIHE

20 Seiten

-

NEUE CR11

6 Seiten

-

PRO-BELT™-RUNDBALLENPRESSE

16 Seiten

-

MINIBAGGER DER D-SERIE

20 Seiten

-

PFLÜGE

32 Seiten

-

HEU- UND FUTTERERNTEMASCHINEN

24 Seiten

-

TL-LADER

16 Seiten

-

BOOMER SERIE 20-50

16 Seiten

-

KOMPAKTRADLADER

12 Seiten

-

T4S

20 Seiten

-

T4-BAUREIHE

20 Seiten

-

T6-BAUREIHE

36 Seiten

-

SCHEIBENEGGEN SDM UND SDH

2 Seiten

-

T5 Electro Command

28 Seiten

-

BR6OOO

16 Seiten

-

ROLL BELT

20 Seiten

-

NEUE BRAUD HOCHLEISTUNGS-BAUREIHE

32 Seiten

-

TD4F

12 Seiten

-

T4LP

12 Seiten

-

BigBaler

24 Seiten

-

Prospekt - T4 - Tier 4A

20 Seiten

-

2022 TH RANGE

24 Seiten

-

T3F RANGE

8 Seiten

-

NEW T4FNV ROPS T4F CAB

12 Seiten

-

NEW BRAUD HIGH CAPACITY RANGE

32 Seiten

-

ROLL BALER

24 Seiten

-

BIGBALER PLUS

32 Seiten

-

TC RANGE

32 Seiten

-

FR FORAGE CRUISER - EN

36 Seiten

-

T7 Heavy Duty

36 Seiten

-

TL LOADERS

16 Seiten

-

T5 RANGE

20 Seiten

-

TC5.30

16 Seiten

-

CX7 & CX8

44 Seiten

-

CR Revelation

48 Seiten

-

T8 Genesis with PLM Intelligence

4 Seiten

-

T7 RANGE

56 Seiten

-

Mowers Tedders rakes

8 Seiten

-

TH-RANGE

20 Seiten

-

D125 C, D150 C, D180C

11 Seiten

-

BC5OOO

8 Seiten

-

BB9090 PLUS

8 Seiten

-

combine headers

32 Seiten

-

Precision Land Managemen

40 Seiten

-

T9 - Tier 4a

24 Seiten

-

T8 - Tier 4B

32 Seiten

-

T8 - Tier 4a

30 Seiten

-

T7 Standard Wheelbase

34 Seiten

-

T6 - Tier 4a

28 Seiten

-

T7 Long Wheelbase

36 Seiten

-

T7 - Tier 4a

28 Seiten

-

T6 - Tier4B

32 Seiten

-

T5 - Tier4B

28 Seiten

-

T5 - Tier 4a

24 Seiten

-

T4 Powerstar - Tier 4a

20 Seiten

-

T4 F

16 Seiten

-

T3F

12 Seiten

-

T3000

12 Seiten

-

Boomer Easydrive

8 Seiten

-

Boomer 25

4 Seiten