Katalogauszüge

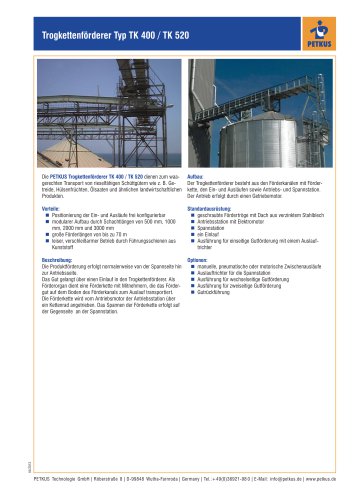

Trough Chain Conveyor Type TK 200 / TK 300 The purpose of the PETKUS Trough Chain Conveyor TK 200 / TK 300 Standard Equipment: is the horizontal transport of free flowing, bulky products such as grain, Screwed conveyor troughs with a roof of galvanized sheet steel pulses, oilseeds and similar agricultural products. Drive station with electric motor Tensioning Station Advantages: Inlet Model for the unidirectional transport of products Positioning of the inlets and outlets freely configurable Modular design through duct lengths of 500 mm, 1000 mm, Options: 2000 mm and 3000 mm Large conveying distances of up to 70 m Manual, pneumatic or motorized intermediate outlets Quiet, low-wear operation due to plastic guiding rails Outlet hopper for the tensioning station Model for the reversible transport of products Description: Model for the double-sided transport of products Device for transporting the product back The transport of the product is usually performed from the tensioning station to the drive station. The product is transported into the Trough Chain Conveyor over the inlet. A conveyor chain with paddles moves the material along the circular bottom of the conveyor trough to the outlet. The conveyor chain is driven by a sprocket by the drive station. The conveying belt is tensioned on the opposite side by the tensioning station. Construction: The Trough Chain Conveyor is equipped with conveyor troughs, a conveyor chain, inlets and outlets as well as the drive and the tensioning station. The drive is operated with a gear motor. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98 0

Katalog auf Seite 1 öffnen

Trough Chain Conveyor Type TK 200 / TK 300 Technical alteration reserved. H E PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98 0 | E-mail: info@

Katalog auf Seite 2 öffnenAlle Kataloge und technischen Broschüren von PETKUS Technologie GmbH

-

Pendelbecherelevator PB 400

2 Seiten

-

Universalreiniger F 12 / P 12

2 Seiten

-

Vorreiniger V 12 / V 15

2 Seiten

-

Universalreiniger U 12 / U 15

2 Seiten

-

Zellenausleser ZK / ZL

2 Seiten

-

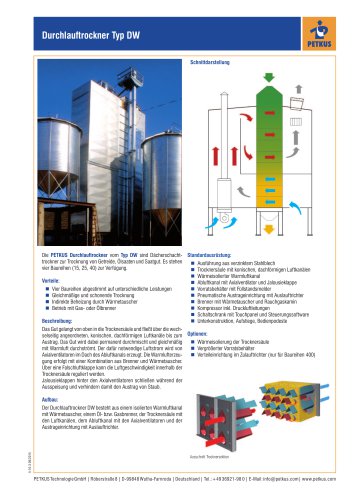

Durchlauftrockner Typ DW

2 Seiten

-

Gewichtsausleser G 05 f

2 Seiten

-

Gewichtsausleser Typ G 20

2 Seiten

-

Gewichtsausleser Typ G 30 / G 40

2 Seiten

-

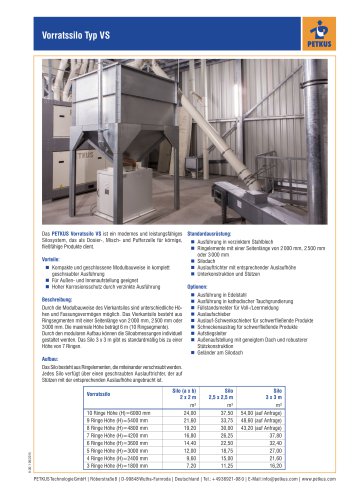

Vorratssilo Typ VS

2 Seiten

-

Glattwandsilo GWS

2 Seiten

-

Profilwandsilo Typ PWS

2 Seiten

-

Muldenband Typ MB 300 / MB 400

2 Seiten

-

Becherelevator Typ BE 100

2 Seiten

-

Durchlauftrockner Typ DWU

2 Seiten

-

Dächerschachttrockner DD

2 Seiten

-

Zellenausleser ZA

2 Seiten

-

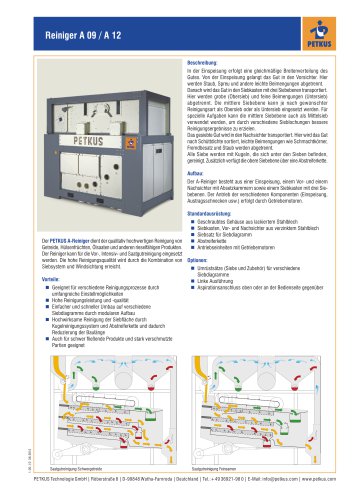

A-Reiniger

2 Seiten

-

Optical sorter OS T roeber

3 Seiten

-

PETKUS K-Series

3 Seiten

-

SE 03

2 Seiten

-

Dust Extraction System

2 Seiten

-

Storage and Buffer Silo

2 Seiten

-

Smooth Wall Silo

2 Seiten

-

Wall Silo PWS

2 Seiten

-

MultiCoater CM 100

2 Seiten

-

Chemical Mixer Type 200

1 Seiten