Katalogauszüge

Agitators & Pumps for biogas

Katalog auf Seite 1 öffnen

AGITATORS FOR BIOGAS Thanks to our years of experience, as the first inventor and manufacturer of the electric agitator, we collect great knowhow and have the possibility to optimize our products throughout. Our biogas agitators are specially designed for use in fermenter, secondary fermenter, digestate tanks as well as pre-pits and hydrolysis. This enables us to guarantee you optimum homogenization of the substrate for maximum gas yields.

Katalog auf Seite 2 öffnen

Propeller Our propellers The propeller influences the efficiency and the result of agitation like no other component of the agitator. However, depending on the tank, the agitator location and the substrate properties, the requirements on the agitator blade vary significantly. We provide you a large selection of varieties. So we can offer you the perfect solution for your application. We develop and manufacture suction and push propeller as well as aerodynamically optimised high-performance blades (HD+). Diameters from 230 mm to 900 mm and speeds from 1,450 rpm to 180 rpm allow specific...

Katalog auf Seite 4 öffnen

Overview Long axis agitators for the biogas sector

Katalog auf Seite 5 öffnen

Long axis agitators GIANTMIX FR light Tube length Especially for concrete- or steel tanks with nearly constant substrate levels Installation depth up to 6 m beneath substrate level Easy assembly and maintenance outside the tank Optional available without engine and only with PTO connection FR light - Closed tank

Katalog auf Seite 6 öffnen

Long axis agitators GIANTMIX FR SP | FR HY SP Tube length Mainly for fermenter and end storages with nearly constant substrate levels Installation depth up to 8 m beneath substrate level Vertically adjustable through upper link ±11° optional ±30° through hydraulic cylinder or pinion rack Easy assembly and maintenance outside the tank Optional available without engine and only with PTO connection (FR HY SP) 60 - 88 kW | 540 or 750 rpm | Ø-Propeller 560 - 700 mm

Katalog auf Seite 7 öffnen

Long axis agitators GIANTMIX FR 30° | FR HY 30° Tube length Specially for fermenter and secondary fermenter with nearly constant substrate Installation depth up to 1.5 m beneath substrate level Vertical inclination ± 11° through upper link or optional ± 25° through rack winch Optional PTO with protection for an alternative tractor operation Optional without engine only with PTO (FR HY 30°) 60-88 kW | 540 or 750 rpm | Ø-Propeller 560 - 700 mm

Katalog auf Seite 8 öffnen

Long axis agitators GIANTMIX FR stationary | FR HY stationary Tube length Together with installation console for the stationary installation Installation depth up to 8 m beneath substrate level Optional PTO with protection unit for alternative tractor operation Optional without engine only with PTO (FR HY stationary) 60-88 kW | 540 or 750 rpm | Propeller 560 - 700 mm FR stationary - Closed tank FR HY stationary - Concrete tank 9

Katalog auf Seite 9 öffnen

Long axis agitators GIANTMIX FTX | FTX top mount Tube length For highly viscous substrates with dry matter content up to 15 % For highly viscous substrates with dry matter contents up to 15 % Installation depth up to 8 m beneath substrate level Vertical inclination through hydraulic cylinder +5° / -30°

Katalog auf Seite 10 öffnen

Long axis agitators GIANTMIX FT | FT HY Tube length Installation depth up to 8 m beneath substrate level Horizontal adjustment up to ± 30° through handspindle Vertical adjustment up to ± 30° through hydraulic cylinder Optional PTO with protection for alternative operation with tractor Optional without engine only with PTO (FT HY) 72 - 100 kW | 540 or 750 rpm | Ø-Propeller 580 - 750 mm FT HY with hydraulic cylinder upwards - Concrete tank

Katalog auf Seite 11 öffnen

Long axis agitators GIANTMIX FT top mounting Tube length Especially for an installation on top of the tank Low noise spur gear Oil expansion vessel for lubrication and monitoring of the sea

Katalog auf Seite 12 öffnen

Long axis agitators GIANTMIX AMX | AMX top mounting Tube length Especially for highly viscous substrates with high dry matter content up to 16 % Installation depth up to 6 m beneath substrate level Vertical inclination through hydraulic cylinder +5° / -30° GIANTMIX AMX top mounting for installation on top of the tank AMX top mounting - Closed tank 13

Katalog auf Seite 13 öffnen

Long axis agitators Rekordmix Optional with trolley Standard 100 cm / Narrow 58 cm Optional with hanging rack EB2 Tube length Application in small tanks with low dry matter content of up to 8 % Motor handle with handhold Multiple bearing stub shaft in oil bath Optional mobile version with trolley Optional mounting on tank wall or opening through brackets for dowelling or hanging rack EB2 REKORDMIX - Closed tank with concrete top

Katalog auf Seite 14 öffnen

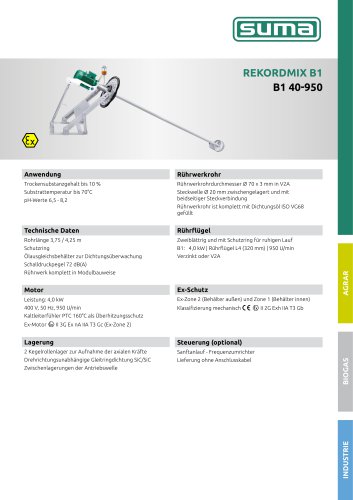

Long axis agitators REKORDMIX B1 Tube length Vertical adjustment through upper link Gastight lead through using EPDM membrane with ring flanges on the foil reduces the risk of cracking due to vibrations

Katalog auf Seite 15 öffnen

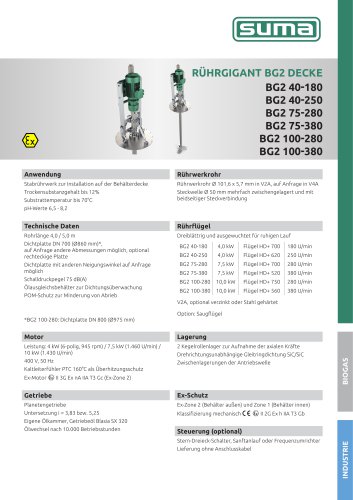

Long axis agitators GIANTMIX BG2 | BG2 top mounting Tube length Especially for installation on top of concrete- and steel tanks Vertical adjustment through upper link Gastight lead through using EPDM membrane with ring flanges on the foil reduces the risk of cracking due to vibrations

Katalog auf Seite 16 öffnen

Long axis agitator GIANTMIX Z5 | Z6 Tractor power Tube length Long axis agitator for open tanks and lagoons Three-point-frame with hydraulic cylinder for vertical adjustment max. 45° Agitator completely modular designed Lubrication by oil bath in the agitator tube, intermediate bearings and balanced agitator propellers guarantee smooth running Z6 - Lagoon with foil cover 17

Katalog auf Seite 17 öffnen

Overview Submersible agitators for the biogas sector Suspension mounting frame EV

Katalog auf Seite 18 öffnen

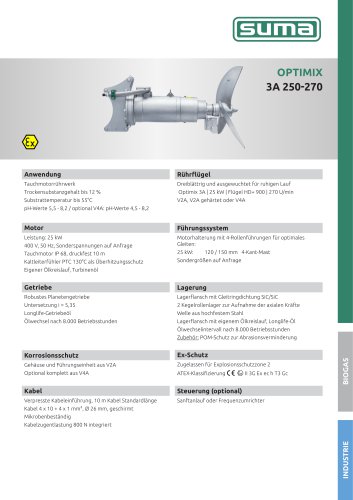

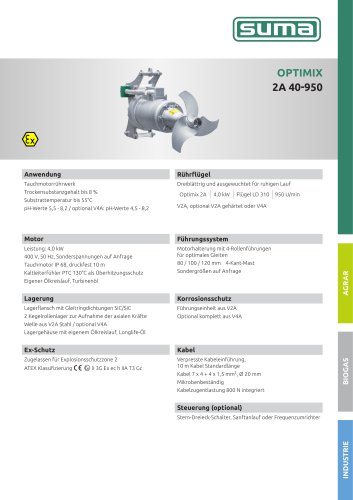

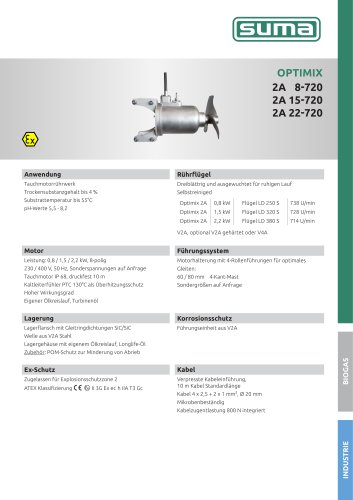

Submersible agitators Submersible agitator OPTIMIX Thanks to our modular design, our submersible mixers can be individually combined in regard to motor power, gear, propeller and mast size. This enables us to offer an agitator that is optimally matched to your needs. All our submersible mixers are suitable for substrate temperatures of up to 55°C and have separated oil chambers for motor, gear and bearing housing. Our special SUMA mechanical seal SiC/SiC seals the rotating shaft to the bearing flange and prevents substrate from entering the agitator blade bearing. Microbe-resistant cable...

Katalog auf Seite 19 öffnenAlle Kataloge und technischen Broschüren von SUMA Rührtechnik

-

OPTIMIX 2G

2 Seiten

-

OPTIMIX 3G 250-270

2 Seiten

-

RÜHRGIGANT AMX

2 Seiten

-

REKORDMIX B1

2 Seiten

-

OPTIMIX 2G 150-275

2 Seiten

-

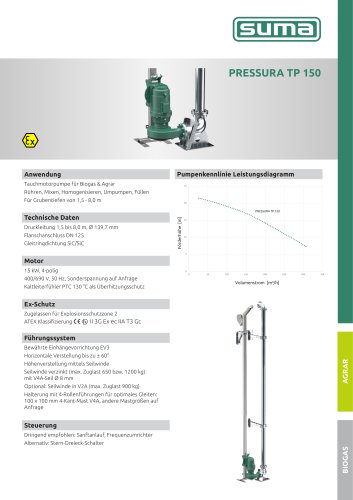

SUMA Pumpe Pressura TP

2 Seiten

-

SUMA Pumpe Pressura LW

2 Seiten

-

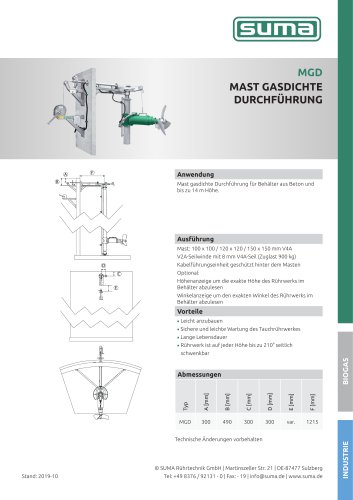

SUMA MGD

1 Seiten

-

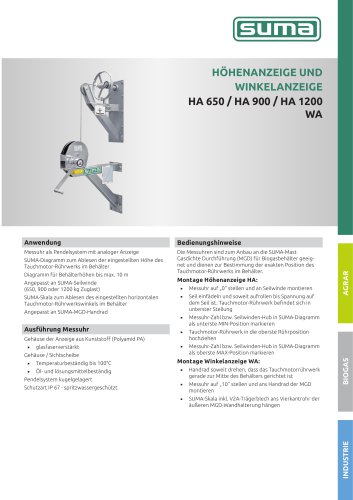

SUMA Höhenanzeige

2 Seiten

-

SUMA EV3 light

1 Seiten

-

SUMA Einhängevorrichtung EV

2 Seiten

-

SUMA GDD

2 Seiten

-

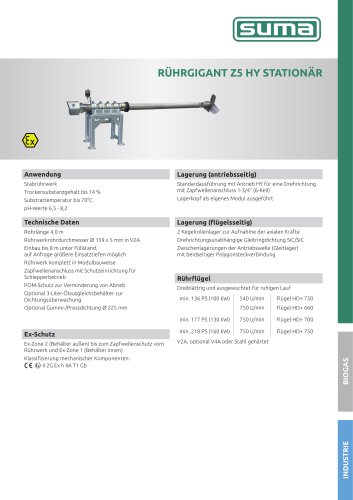

SUMA Rührgigant Z5 stationär

2 Seiten

-

SUMA Rührgigant Z5

2 Seiten

-

SUMA Rührgigant Z5 HY

2 Seiten

-

SUMA Rührgigant Z4

2 Seiten

-

SUMA Rührgigant FT HY

2 Seiten

-

SUMA Rührgigant FT HY stationär

2 Seiten

-

SUMA Rührgigant FR HY stationär

2 Seiten

-

SUMA Rührgigant FR HY SP

2 Seiten

-

SUMA Rührgigant FR HY 30

2 Seiten

-

SUMA Rührgigant Z-MIX

4 Seiten

-

SUMA Rührgigant S-MIX

2 Seiten

-

SUMA Rührgigant FTX Decke

2 Seiten

-

SUMA Rührgigant FTX

2 Seiten

-

SUMA Rührgigant FT stationär

2 Seiten

-

SUMA Rührgigant FT Decke

2 Seiten

-

SUMA Rührgigant FR light

2 Seiten

-

SUMA Rührgigant FR Stahlturm

2 Seiten

-

SUMA Rührgigant FR Decke

2 Seiten

-

SUMA Rührgigant BG2 Decke

2 Seiten

-

SUMA Rührgigant AMX Decke

2 Seiten

-

SUMA Rührgigant AMT SL

2 Seiten

-

SUMA Rührgigant AMT LL

2 Seiten

-

SUMA Rührtunnel

2 Seiten

-

SUMA Optimix ECO mobil

2 Seiten

-

SUMA Optimix 4G

2 Seiten

-

SUMA Optimix 3G 25kW

2 Seiten

-

SUMA Optimix 3G 10kW

2 Seiten

-

SUMA Optimix 3A

2 Seiten

-

SUMA Optimix 2G stationär

2 Seiten

-

SUMA Optimix 2G 185-275

2 Seiten

-

SUMA Optimix 2G 75-380

2 Seiten

-

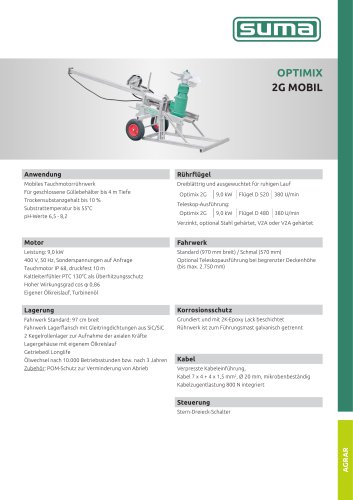

SUMA Optimix 2G mobil

2 Seiten

-

SUMA Optimix 2G 90-75 XT

2 Seiten

-

SUMA Optimix 2G 90-75

2 Seiten

-

SUMA Optimix 2A 15kW

2 Seiten

-

SUMA Optimix 2A 13,5 kW

2 Seiten

-

SUMA Optimix 2A 9kW

2 Seiten

-

SUMA Optimix 2A 4kW 950 U/min

2 Seiten

-

SUMA Optimix 2A 720 U/min

2 Seiten

-

SUMA Optimix 2A 4 kW

2 Seiten

-

SUMA Rührgigant MZR Lagune

2 Seiten

-

SUMA Rührgigant MZR

2 Seiten

-

SUMA Rührgigant Z5

2 Seiten

-

SUMA Rührgigant Z3

2 Seiten

-

SUMA Rekordmix

2 Seiten

-

SUMA Rührgigant BG2

2 Seiten

-

Rührgigant FR stationär

2 Seiten

-

INDUSTRIERÜHRWERKE

12 Seiten

-

RÜHRGIGANT FR SP

2 Seiten

-

RÜHRGIGANT FR 30

2 Seiten

-

RÜHRGIGANT FT

2 Seiten

-

RÜHRGIGANT Z6

2 Seiten

-

OPTIMIX2G 150-275

2 Seiten