Extractos del catálogo

the new generation AURORA MODULAR PLANSIFTER

Abrir la página 1 del catálogo

the new generation Modular Square Plansifter The Aurora is a new generation of Plansifter which is designed by using new and innovative concepts of using modules, which allow a total flexibility from 2 sections to 4, 6 and 8 sections to suit the specific requirements of its usage. By using a new manufacturing technique which allows fast delivery times to respect the customer’s demands. APPLICATION & SCOPE OF USE The Aurora has been designed to sift and grade granular and floury products in flour, maize (corn), durum, rye and rice mills. It can also be applied for the sorting of free flowing...

Abrir la página 3 del catálogo

Modular Concept Higher sifting efficiency with compactness This innovative concept consists of the central oscillating drive mechanism to which there are two sections attached by means of 2 carrier arms. Starting from here any even number of sections can be attached limited to a maximum number of 8 sections and vice versa they can be removed. The oscillating drive system consists of a central shaft to which the counter weights, which are adjustable are attached. The top and bottom ends of the shaft are housed in double conical cylindrical bearings. The shaft is driven by a motor, special...

Abrir la página 4 del catálogo

Efficient Sifting And Sanitation Higher sieve loads are achieved by using the AURORA (G) frames and AURORA sieve fabric and sieve tray cleaners an extra 22% sifting area is achieved. The Alapala type G, N and S sieves can be used. Further more, a constant sifting capacity is achieved with the best through rates with minimum sieve cleaning and low easy maintenance. After the sieves have been placed in the section they are pressed and clamped by a special pressure clamping device which is independently adjustable from all four corners. High levels of sanitation are achieved due to the...

Abrir la página 7 del catálogo

FEATURES & ADVANTAGES Modular section concept The modular concept allows the number of sections to be adjusted as required Fast manufacturing and delivery time Higher loads and excellent sifting capacity in the minimum of space 22% extra sieving are by using the Type G AURORA boxes with a maximum of 30 sieves per section Combined AURORA cleaners for fabric sieves and sieve boxes Constant sifting capacity Vertical & horizontal dividing possibility at any required level Maximum sanitation by the use of stainless steel & food grade synthetics Excellent insulation against humidity and...

Abrir la página 9 del catálogo

Minimum maintenance cost,

Abrir la página 11 del catálogo

Aurora New Generation Modular Plansifter

Abrir la página 14 del catálogo

Technical Features AURORA 430 AURORA 630 Number of Compartments Number of Sieves per Compartment Timber Typ N (m2) Frame Typ G (m2) Net Sifting Area In Aluminium Typ N (m2) Frame Typ G (m2) Power Motor with 6 - Poles (Kw) Net Weights Gross Brut Gross Volume (m3)

Abrir la página 15 del catálogo

ALAPALA’S NEW STATE OF THE ART MILLING TECHNOLOGY. pusula reklamevi Minimum maintenance cost, maximum hygiene. “Passion for milling since 1954” HEADQUARTERS & FACTORY : ORGANİZE SANAYİ BÖLGESİ, 12.CADDE NO: 15 PK.54 19040 ÇORUM, TURKEY SALES & MARKETING www.alapala.com • www.alapalaworld.com

Abrir la página 16 del catálogoTodos los catálogos y folletos técnicos Alapala

-

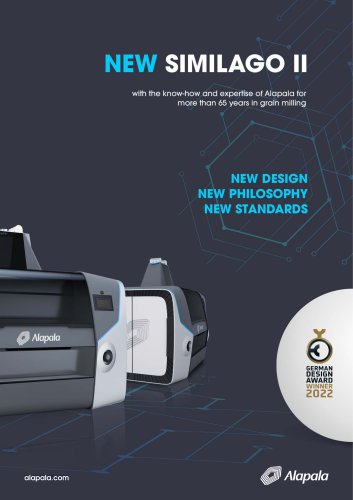

SIMILAGO II

16 Páginas

-

Products & Technical Catalogue

164 Páginas

-

GRAIN STORAGE & HANDLING SYSTEMS

17 Páginas

-

NEW SIMILAGO II

12 Páginas