Extractos del catálogo

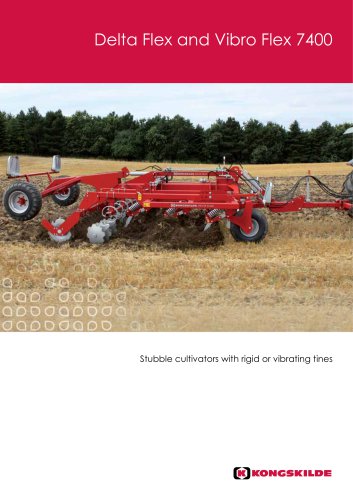

Stubble cultivators with rigid or vibrating tines

Abrir la página 1 del catálogo

What is obtained by correct stubble cultivation? Incorporation of straw and field residues • Quick decomposition due to the mixing of both straw and plant residues with the soil • Utilizing the moisture in the soil just after harvest • Establish an optimal climate for microbes to work in Establishment of a stale seedbed for germination of weed seeds • Shallow cultivation directly after harvest will encourage lost seeds and weed seeds to germinate • Seedbed preparation for establishing intermediate crops such as mustard, oil radish etc. • No slug nutrition Preparation of a seedbed in mulch...

Abrir la página 2 del catálogo

Common platform offers flexibility Main advantages: • Reliable heavy duty construction • Blockage-free operation through large frame clearance and tine spacing • Safe access for wearing part replacement when wings folded to vertical • Wing pressure system allows machine to follow field contours • Simple adjustment of the working depth by pin/hole system • Changing the working depth has no effect on the levelling system settings after basic adjustment • Transport wheels at the rear for safe road transport • Reduced soil compaction on headlands through wide profile transport tyres • Modular...

Abrir la página 3 del catálogo

Delta Flex Rigid tine stubble cultivator Main advantages: • Rigid tines ensure an even working depth • Working depths from 6 - 25 cm in one pass • Fitted with wing shares a full cut across the entire working width is achieved • Without wing shares fitted, deeper loosening down to 25 cm is possible in one pass • Optimal mixing of straw and residues is the result of the special curved stems, which encourage a rolling soil action • Release force of 400 kg on the tip of the point • High release clearance of 25 cm • Easy conversion from shearbolt to non-stop version Benefit for the user: • Delta...

Abrir la página 4 del catálogo

Vibrating tine stubble cultivator Main advantages: • The constantly-vibrating Vibro Flex tines leave an open soil structure • An extra crumbling effect is obtained, as the soil breaks up in the natural fracture lines • 4 rows of tines for a more intensive mixing of field residues with soil in one pass • Heavy duty VFM-spring with built-in backwards and sideways overload protection • Constant working depth as share point always operates directly under the tine flex point • Working depths from 6 – 15 cm in one pass and up to 25 cm in the following pass • Wide range of heavy duty high quality...

Abrir la página 5 del catálogo

Levellers Intensive levelling of the soil after the cultivator tine section is the premium criterion for quality reconsolidation. For the Delta Flex and Vibro Flex 7400 ranges Kongskilde offers 2 options for levelling. Disc leveller • Constant and blockage-free rotation. • One-step depth adjustment together with the cultivation depth • Frame connection via Kongskilde VTH spring, acting as suspension • Further mixing of plant residues with soil for quicker decomposition. • Mounted in sections, with 2 0460mm notched discs on each section. • Spindle depth adjustment Hockey stick leveller •...

Abrir la página 6 del catálogo

Crumble roller • Well-known Ø550 mm diameter crumble roller • Good choice in most soil types, with special advantage of constant rotation. • Cost-effective alternative to Max Pack and Vibro Pack rollers; in many cases a substantial packing and crumbling effect is achieved. Shares • Wide range of genuine high quality shares for Delta Flex and Vibro Flex 7400 to suit different applications. • Made in hardened boron steel for a long lifetime. Front disc section (Vibro Flex 7400) To cut and separate plant residues (maize, oil seed rape etc) an independent disc section can be used in front of...

Abrir la página 7 del catálogo

Work Width Transport width Cat. Weight incl. crumble roller Front wheels Tine spacing Power requirements hp Subject to be changed without notice. 101001585 EXP/GB/Stubble cultivation/BRO/0412 mail@kongskilde.com www.kongskilde.com (k) kongskii.de Kongskilde Industries A/S Tel. +45 33 68 35 65 adding value to the green world

Abrir la página 8 del catálogoTodos los catálogos y folletos técnicos KONGSKILDE Industries A/S

-

Vibro Seeder

4 Páginas

-

1-rotor rakes

8 Páginas

-

Rotavator

6 Páginas

-

Kongskilde Ploughs

28 Páginas

-

Complete diet mixers

32 Páginas

-

NS 1500 - 1900

2 Páginas

-

Vibro Compact

4 Páginas

-

Tedders

8 Páginas

-

Front Terra C

2 Páginas

-

Semi-mounted reversible ploughs

8 Páginas

-

SB4000/SB5200

4 Páginas

-

Vibro Crop 2017

4 Páginas

-

Rotary rakes with 2 rotors

8 Páginas

-

Clean cut 2021

20 Páginas

-

Trailed forage harvesters 2021

12 Páginas

-

VIBRO TILL 2900

8 Páginas

-

Delta Flex and Vibro Flex 7400

8 Páginas

-

COMBI JET

8 Páginas

-

COMBISEED HT3000S-HT4000S

4 Páginas

-

FLEXI DRILL

4 Páginas

-

MULTI JET

8 Páginas

-

KONGSKILDE FRONT TERRA DISC

2 Páginas

-

KONGSKILDE TERRA-D

2 Páginas

-

KONGSKILDE DELTA SHEAR BOLT VERSION

4 Páginas

-

VIBRO FLEX 2000/4000/4200/4300

6 Páginas

-

VIBRO FLEX 7400

8 Páginas

-

VIBRO FLEX FRONT MOUNTED

6 Páginas

-

VIBRO TILL 2900 SF

8 Páginas

-

VIBRO TILL 8200 SF

12 Páginas

-

BETTER FUEL EFFICIENCY

2 Páginas

-

ÖVERUM CT-F

2 Páginas

-

XLD PLOUGH BODY

5 Páginas

-

KONGSKILDE MS-MT

2 Páginas

-

VIBRO CROP VCR

2 Páginas

-

KDC 8000

4 Páginas

-

ASPIRATOR PRE-CLEANERS - KF

8 Páginas

-

FAN GUARD

2 Páginas

-

PNEUMATIC GRAIN CONVEYING

16 Páginas

-

R+ 1610

8 Páginas

-

R+ 2 ROTORS

8 Páginas

-

Rear mounted drum mower - CM 305

2 Páginas

Catálogos archivados

-

Trailed forage harvesters 2016

12 Páginas

-

Clean cut 2016

20 Páginas