Site web :

Anaergia Technologies GmbH

Site web :

Anaergia Technologies GmbH

Groupe : Anaergia

Extraits du catalogue

UTS SEPARATOR FSP, MSU AND MSU PRO MAXIMUM SEPARATION │ MINIMUM OPERATION COSTS

Ouvrir le catalogue en page 1

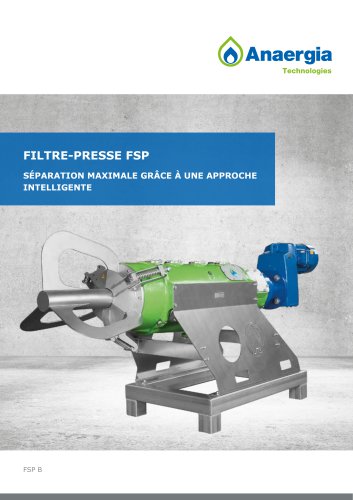

For more than 15 years, we have been developing and manufacturing filter screw press (FSP) separators that provide consistently high separation and throughput performance with a very long service life. Additionally, with high quality standards and innovative detailed solutions, there is a very low maintenance requirement for the unit. The hinged, quick-release press housing offers easy access to the screen and screw, while the inspection openings in the inlet and screen housing make cleaning and maintenance work quick and easy. The auger used in our separators has tungsten carbide cladding....

Ouvrir le catalogue en page 2

A UNIQUE TECHNOLOGY FSP SEPARATORS SEPARATION OF FILTER AND PRESS AREA Maximize the capacity, minimize the wear. » Radially moving filter screen head is separated from the high-pressure-resistant press screen basket by a fixed wear ring made of a specially selected plastic » Screw flights end at the wear ring » No pressure is exerted on the filter screen basket by the press. As a result, the entire screen surface area is available for dewatering FOLDING PRESS HOUSING WITH QUICK-RELEASE Quick access to screen and screw without excessive physical effort. » Screw press housing with press...

Ouvrir le catalogue en page 3

INSTALLATION EXAMPLE: SEPARATORS FSP A AND B Our separators are designed to be extremely robust and are thus consistently manufactured for difficult applications. In the process, the highest possible throughput is achieved for the separation of manure, digestate, mash, and other substances. Maintenance and service tasks can be carried out quickly and easily on-site without disassembly of the press head and pipelines – reducing overall downtimes to a minimum. An important element of our service is providing an individual design for every project through the use of a mass, nutrient, and cost...

Ouvrir le catalogue en page 4

We have developed our FSP A stainless steel separator series based on the very high requirements of industry and high-performance agriculture. Typical areas of application include: » Paper, pulp and wood-processing industry (e.g. MDF): Dewatering of pulp, rejected fine material and fibrous sludges, as well as fibre extraction from wastewater and process water. » Food industry: Fruit and vegetable processing, dewatering of distiller's wash and mash, wastewater and waste treatment » Meat processing industry: Slaughter waste, stomach and intestinal content, wastewater » Recycling of plastics:...

Ouvrir le catalogue en page 5

MOBILE SEPARATION SERVICE WITH THE MSU UNCOMPLICATED PLUG & PLAY SOLUTION The MSU (Mobile Separation Unit) is a compact plug & constantly regulated inlet pressure that ensures optimi- play solution for flexible separation of slurry and dige- zed material feed. The compact arrangement of the en- tire unit allows easy transport, e.g. by trailer. This unit is ideal for you if you want to separate slurry Depending on the design, the MSU can be used in vari- and digestate at different locations on your farm. It can ous ways: in classic separation mode, in bedding mode also be worthwhile for...

Ouvrir le catalogue en page 6

MSU PRO - MOBILE SEPARATION „ADVANCED“DRIVE UP, CONNECT AND GO The MSU Pro is an extension of the MSU. The additional conveyor belt with a length of 6 m can be swiveled up to 180°. With a drop height of 4 m, the MSU Pro is even more flexible in use than the MSU. A level sensor on the receiving hopper of the conveyor belt provides additional operational safety. It shuts down the system in the event of a plug breakthrough/liquid leakage at the separator.

Ouvrir le catalogue en page 7

Konzeption und Umsetzung: PLAN B - www.planb-suedwestfalen.de OUR ANAERGIA TECHNOLOGIES We offer solutions for the following applications: » Pump Technology » Mixing Technology » Separation » Extrusion Technology » Screening & Sorting » Size Reduction » Organic Polishing » Conveyor Technology Anaergia Inc. Headquarters Burlington, Ontario, Canada T: +1 905-766-3333 Anaergia UK Ltd. Sales Office St. Neots, Cambs, United Kingdom T: +44 1480-477-608 DB Technologies BV Product Company Oldenzaal, Netherlands T: +31 541-745031 Anaergia Technologies GmbH Product Company Lippetal, Germany T: +49...

Ouvrir le catalogue en page 8Tous les catalogues et fiches techniques (PDF) Anaergia Technologies GmbH

-

CAISSON DE SERVICE CLASSIQUE

6 Pages

-

CAISSON DE SERVICE PRO

6 Pages

-

POMPES UTS

6 Pages

-

FILTRE-PRESSE FSP

6 Pages

-

MOBILE SEPARATION MSU LIGHT

2 Pages