Site web :

Big Dutchman

Site web :

Big Dutchman

Extraits du catalogue

Avi Max transit The multi-tier system for hygienic, efficient and successful broiler growing

Ouvrir le catalogue en page 1

AviMax transit Successful broiler production and automatic bird transport AviMax transit is an innovative manure belt system developed by Big Dutchman for broiler growing. It has been designed for hygienic management conditions and maximum profitability. This means: 4 ealthy and uniform birds, increased h growth rate, high feed conversion, up to one batch more per year; 4 to four times higher stocking densities two compared to production on the floor, leading to a significantly improved utilisation of the house surface area and to reduced energy costs for heating and/or cooling; 4 imple...

Ouvrir le catalogue en page 2

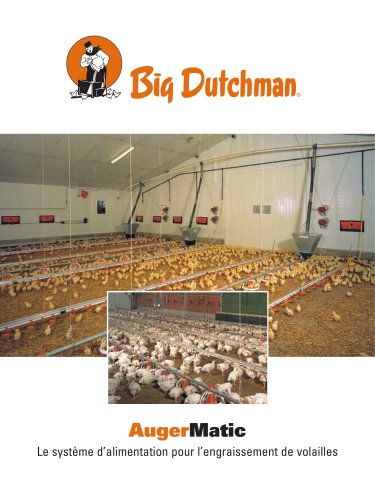

Feed supply – reliable and adapted to the birds’ needs at any age A FlexVey spiral transports the feed from the silo through the continuous weigher FW99 and into the house. Here, the feed is dispensed into feed pans by feed valves in every tier. Every compartment is equipped with two of our well-proven FLUXX feed pans, which satisfy the needs of both day-old chicks and of heavy broilers in the final growing phase. After the day-old chicks are moved in and during the first days, the 360° flooding mechanism provides a high feed level in the pan, without additional labour requirements. As long...

Ouvrir le catalogue en page 3

Inspection cart - easy monitoring of the birds The Big Dutchman inspection cart ensures optimal monitoring of the flock and makes it easy to move broilers in and out, especially in the top tiers. The height of the inspection cart can be adjusted as required. A rail guides the cart, which runs on the floor, safely along the system. The cart can be locked in place in any position by means of a brake. High corrosion protection Excellent product quality and reliability are part of the Big Dutchman philosophy. For this reason, all grilles installed in the AviMax transit system are treated with a...

Ouvrir le catalogue en page 4

Manure removal with manure belts – simple, efficient and clean The manure drops onto polypropylene (PP) manure belts underneath the system. After moving in the day-old chicks, manure should be removed by running the manure belts for the first time no later than one week after the moving-in date. In weeks 2 and 3, the manure should be removed every other day, and from week 4 onwards, the belts should run daily. This ensures a relatively low ammonia content in the house air and prevents fly problems. The end set is galvanized and thus protected against corrosion. The stainless steel manure...

Ouvrir le catalogue en page 5

Easy moving-out of ready-for-slaughter broilers For the moving-out procedure, the pivoting floors are simply opened upwards, with little effort, so that the broilers slide onto the manure belt from a very low height of just a few centimetres. While this work is done, the barn lights are dimmed (lights out). Since the floor is opened upwards into the cage area, there is sufficient headroom above the manure belt for the transport of the broilers. Thanks to this innovative moving-out method, AviMax transit requires significantly less building height than other systems. In many cases, this...

Ouvrir le catalogue en page 6

ViperTouch climate and production computer – secure, comfortable, easy to use ViperTouch is the basis for reliable and secure climate and production control in your barn! The computer’s outstanding features include: 4 oloured 7-inch or 10-inch touch C screen: Functions you use on a daily basis are immediately available in the menu. Relevant curve trends are displayed as graphs. 4 ustomisable user interface: You can C design the display just as you require and prefer. 4 odular hardware: Easy to extend M whenever you need new functions. 4 oftware updates: Easy to implement S when...

Ouvrir le catalogue en page 7

AviMax transit is available with different ✓ Compartment width: 150 or 180 mm types that can be supplied as per your dimensions: ✓ Tier distance: 655 or 775 mm requirements. 4 Compartment length: 2 412 mm These dimensions result in a number of system AviMax 150 transit - 2412 Width x Length = 150 x 2 412 mm AviMax 180 transit - 2412 Width x Length = 180 x 2 412 mm Tier distanceRecommended number of birds per compartment depending on broiler weights Final weight (g) We recommend a stocking density of 50 kg/m2. \ Dutchman. Europe, Middle East & Africa: Big Dutchman International GmbH P.O. Box...

Ouvrir le catalogue en page 8Tous les catalogues et fiches techniques (PDF) Big Dutchman

-

Plateau d'aliment Vista 360

2 Pages

-

Volière NATURA Visio

2 Pages

-

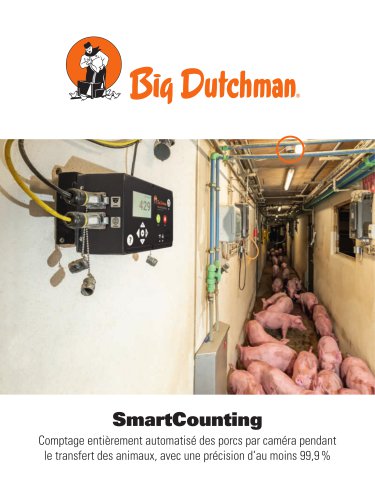

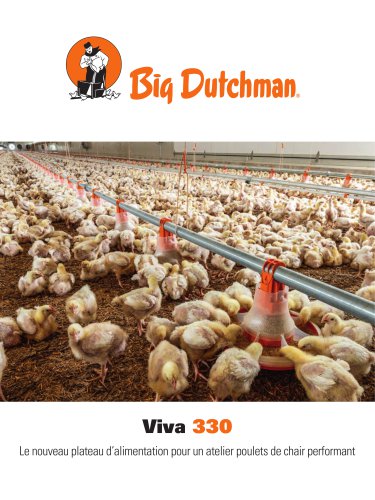

Plateau d'aliment Viva 330

2 Pages

-

Éclairage LED

12 Pages

-

Systèmes d‘admission d’air

12 Pages

-

OneLite & DuoLite

2 Pages

-

Dispositifs d‘alarme

4 Pages

-

Échangeur de chaleur Earny 2

6 Pages

-

SiloCheck AIR

2 Pages

-

Cheminées d'extraction d'air

8 Pages

-

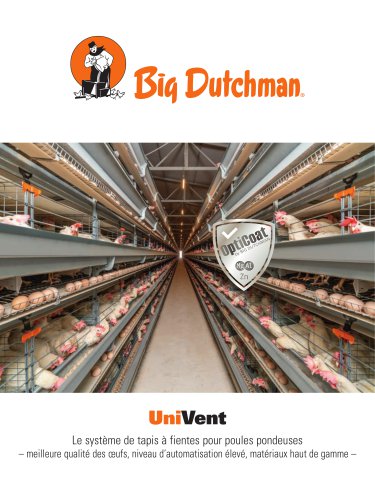

UNIVENT-Starter 680-plus

2 Pages

-

Pesage d‘animaux

6 Pages

-

Élevage des truies

16 Pages

-

Fosses à fientes

4 Pages

-

Élevage de reproducteurs chair

18 Pages

-

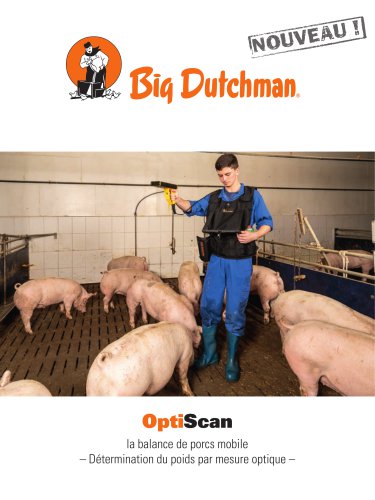

OptiScan

2 Pages

-

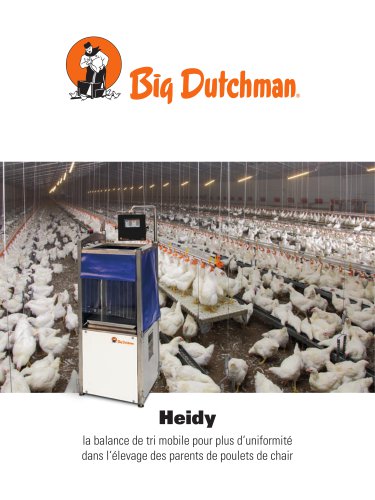

Balance de tri Heidy

2 Pages

-

Ventilation CombiTunnel

6 Pages

-

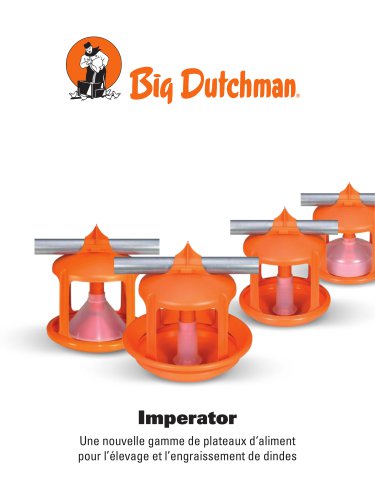

Plateau d'aliment Imperator

2 Pages

-

Bâtiment bien-être Havito

4 Pages

-

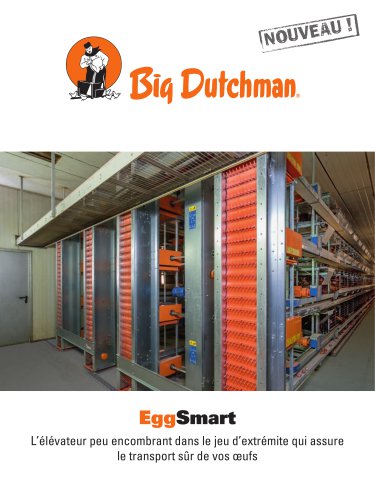

Élévateur EggSmart

2 Pages

-

Des équipements innovants

4 Pages

-

Plafonnier Helios

2 Pages

-

Nourrisseurs automatiques

4 Pages

-

Systèmes de caillebotis

4 Pages

-

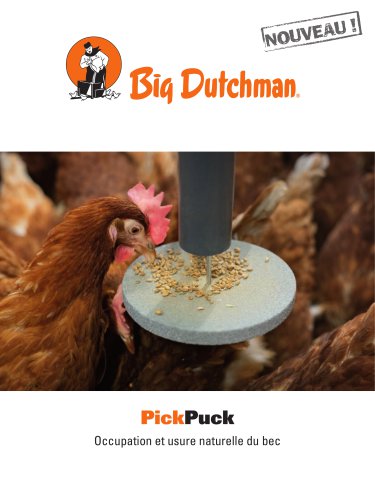

Accessoire de jeu PickPuck

2 Pages

-

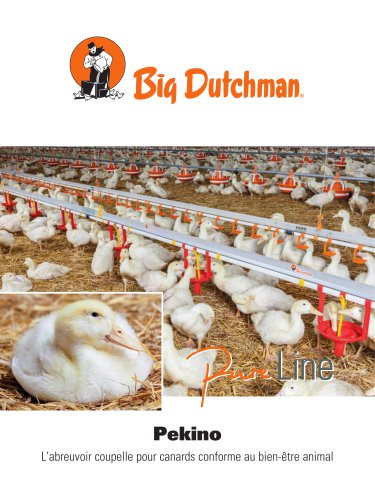

Abreuvoir coupelle Pekino

2 Pages

-

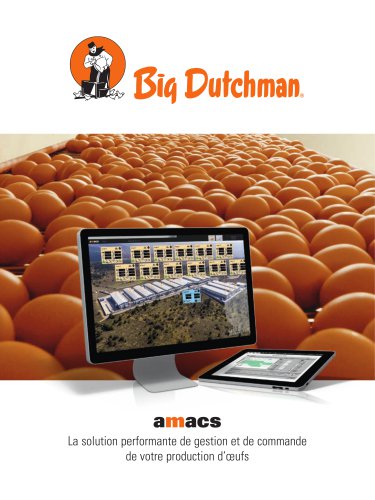

Gestion d'élevage avec amacs

12 Pages

-

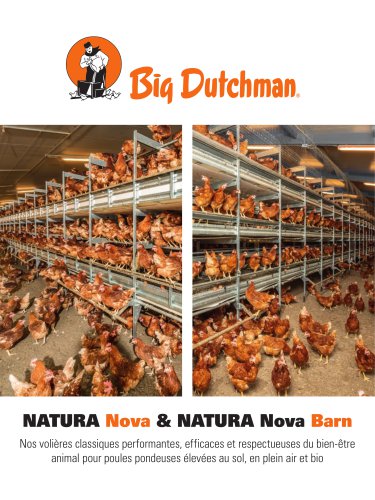

Volière NATURA 70

6 Pages

-

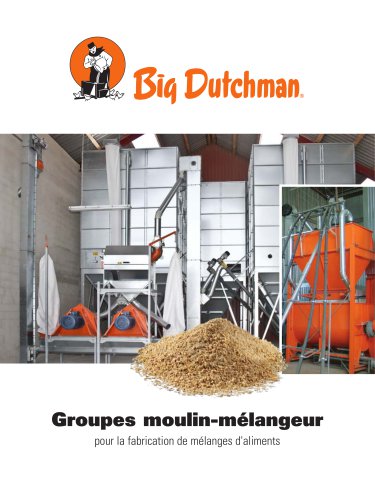

Groupes moulin-mélangeur

6 Pages

-

Systèmes de refroidissement

4 Pages

-

Laveur d’air Porcus

4 Pages

-

Réglette étanche LED

2 Pages

-

Kit de rattrapage LED

2 Pages

-

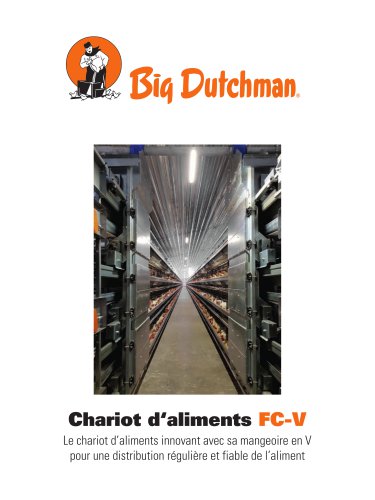

Chariot d‘aliments FC-V

4 Pages

-

Balance de tri TriSort pro

4 Pages

-

DOL 53 – le capteur NH3

2 Pages

-

Sharky 430 cleaning robot

2 Pages

-

CompoTower fermenter

4 Pages

-

PURO air cleaning system

4 Pages

-

OptiSec Porco belt dryer

4 Pages

-

BD plastic slat

2 Pages

-

AviMax sliding broiler cage

2 Pages

Catalogues archivés

-

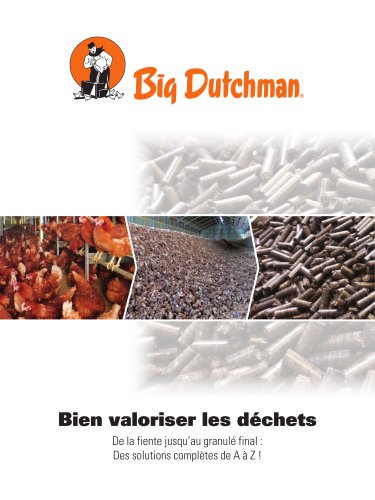

Bien valoriser les déchets

12 Pages

-

Pondoir collectif RelaxGo

2 Pages