Site web :

Buschhoff GmbH & Co.

Site web :

Buschhoff GmbH & Co.

Extraits du catalogue

Top-notch mobile concentrated feed plants ■ Maximum performance with easy handling. ■ User-friendly residue-emptying of the complete plant. ■ Minimum maintenance cost by way of few wear parts. ■ Coarse meal, rolled grain, and other feed components are directly (without rotary valve) fed into the mixer and processed. ■ Pneumatic emptying of the mixer. ■ Feed residue is automatically removed from the mixer bottom by the rotational sucker and discharged. At the same time, high pressure inside the mixer is gradually relieved. ■ An automatic load control caters for a smooth pneumatic discharge. ■ The emptying performance is up to 26 t/h via discharge pipe, via discharge arm up to 60 t/h. ■ The suction/pressure pipes and the discharge arm are at the left side of the truck. The operating position and the hose stowage on the right-hand side remain unobstructed. The new filter unit is integrated within the suction-pressure-mixer. Minimum pressure drag inside the autonomously pneumatic-cleaning filter unit ensures an efficient, continuous sucking throughput. The filter unit is maintenance-free and easily accessible Short conveying distances and fully-opening ball valves ensure low drag and a high conveying performance.

Ouvrir le catalogue en page 1

Flowchart 1. Suction flap 2. Hammer mill 3. Grain rolling unit 4. Rotary piston blower 5. Filter unit 6. Suction-pressure-mixer 7. Rotational sucker 8. Feed oil tank 9. Feed component hopper 10. Discharge pipe 11. Discharge arm Technical data at a glance Drive Blower Suction pipe Mill Grain rolling unit Direct drive by truck engine up to 320 kW (440 PS) or Plant engine Mercedes-Benz OM 501 LA 290 kW (395 PS) Aerzener rotary piston blower with pre-inlet cooling Pipe diameter: 100 mm (90 mm) Hammer mill HF400 with 72 or 100 hard metal hammers Screen cage with two screens Milling...

Ouvrir le catalogue en page 2Tous les catalogues et fiches techniques (PDF) Buschhoff GmbH & Co.

-

Bruised Grain Blower

2 Pages

-

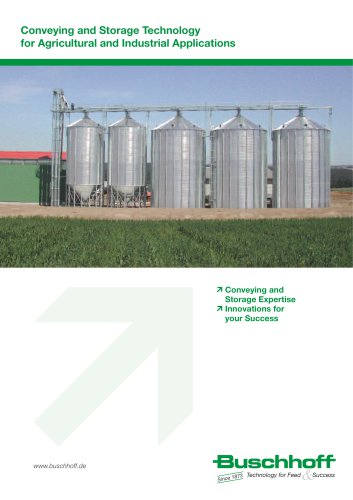

Storage and conveying technology

12 Pages

-

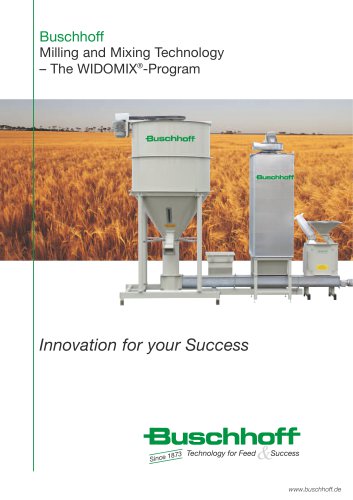

Milling and Mixing Technology

14 Pages

-

TOURMIX 02-VE

2 Pages

-

TOURMIX 03

2 Pages

-

TOURMIX 03 DUO

2 Pages