Extraits du catalogue

C7000 SERIES. Maintenance. Easy access to all drives and maintenance points minimises maintenance effort. The individual components have an multi-layer anti-corrosion coating to protect against rust, dirt and moisture: the best guarantee for long-term value retention and reliability. > PAGE 20 Engine. Powerful 7.7 litre Mercedes-Benz engines 310 – 381 HP (230 – 280 kW) with a high torque reserve provide maximum power in all conditions. Low fuel consumption and low emissions thanks to SCR technology in combination with the EGR system (Stage V). > PAGE 16 Header. The patented Schumacher Easy...

Ouvrir le catalogue en page 2

Grain tank. The grain tank with 8,500 (C7205) or 9,500 (C7206) litre capacity (unloading at 90 l /s) allows long working periods with only short interruptions. Top unloading with a passage height of 4.30 m for easy filling even of high-walled transport vehicles. > PAGE 14 Treshing system. The threshing system is designed for the highest loads at maximum production rates and is equipped with an electronic speed control for the threshing drum (600 mm diameter, 420 – 1,250 rpm). The segments of the threshing basket can be exchanged quickly and easily depending on the grain type. > PAGE 10...

Ouvrir le catalogue en page 3

Features, quality and performance, excellence, unite within a brand with a long and distinguished history.

Ouvrir le catalogue en page 5

BEST CUTTING RESULTS. Perfect cutting results and optimum crop flow.

Ouvrir le catalogue en page 6

Planetary gear transmission: high cutting rates in all harvesting conditions. The feeder auger with full length retractable fingers ensure continuous feed and crop flow. The sensor skids allow the header to follow the contours of the terrain precisely and make instant adjustments to ensure an even cutting height. The offset configuration of the knife sections reduce wear and ensures excellent cutting results in all conditions. The rapeseed kit may be fitted to the grain header for even greater versatility. The sunflower seed kit harvests the sunflower heads only, for optimised harvesting...

Ouvrir le catalogue en page 7

HIGH TRESHING INTENSITY. Unrivalled results in all terrain cottons. THE DETAILS MAKING THE C7000 SUCH A GREAT MACHINE. Even the details of the C7000 Series are astonishing: The feeder housing is fitted with three alternating feeder bars fastened to three chains with toothed support shafts to prevent vibration and allow large headers to be used. The cutting angle is mechanically adjustable (or adjustable with an exclusive optional electrohydraulic system) ensuring continuous crop feed to the threshing system. The heavy-duty electric feeder reverse system for the feed elevator and header...

Ouvrir le catalogue en page 9

CONCAVE ADJUSTMENT. The clearance between the concave and the threshing drum at the input and output can be independently adjusted at the front and rear via electric actuators controlled by the Commander Control. THRESHING DRUM, CONCAVE AND STRAW BEATER. A broad 600 mm diameter threshing drum measuring 1.27 m in width for the 5 straw walker model and 1.52 m in width for the 6 straw walker model, and a multi-segment concave with a pitch of 121° ensure perfect threshing results in all conditions. TURBO SEPARATOR (photo on LH). A third drum situated behind the straw beater increases threshing...

Ouvrir le catalogue en page 10

GRAIN QUALITY. The perfect system for every need. AN INGENIOUS THRESHING SYSTEM. The C7000 Series is equipped with a threshing system built to meet the needs of even the most challenging harvesting job. The sturdy 600 mm diameter threshing drum is designed and built to withstand high stress and strain, to ensure excellent straw and grain quality even in very high production volume conditions. V-belt tension is adjusted automatically in relation to torque to let the system operate at full power in all conditions. The electric threshing drum speed adjustment system varies speed within a range...

Ouvrir le catalogue en page 11

SEPERATION TECHNOLOGY. Outstanding cleaning, minimal losses.

Ouvrir le catalogue en page 12

overload safety system ensures excellent reliability. The dual grain return system An (DGR) has two different operating speeds selectable in relation to the crop processed to ensure complete grain care in all conditions. (optional) electrically operated sieve adjustment system lets the operator adjust An sieve clearance instantaneously in relation to harvesting conditions. IMPECCABLE GRAIN CLEANLINESS WITH DEUTZ-FAHR. Unmistakeable: with DEUTZ-FAHR cleaning and separation technology, the C7000 Series meticulously processes every last grain. The large surface area of the five or six...

Ouvrir le catalogue en page 13

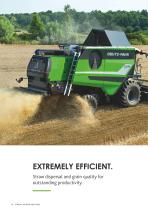

EXTREMELY EFFICIENT. Straw dispersal and grain quality for outstanding productivity. 14 - STRAW CHOPPER AND TANK

Ouvrir le catalogue en page 14

Grain tank. Generous sized grain tank. Unloader, fast and efficient high clearance grain unloading. isaual grain tank monitoring. A double window in the cab lets the operator V visually check the fill level of the tank and the quality of the grain harvested. Straw Chopper, for even more effective material distribution, the straw chopper may also be equipped with deflectors, adjusted electrically from the cab, to adjust spreading to weather conditions. STRAW CHOPPER AND CHAFF SPREADER. The integrated straw chopper is engaged and disengaged directly from the cab. The high intensity...

Ouvrir le catalogue en page 15

HIGH PERFORMANCE. Outstanding performance with low running and maintenance costs. ENGINES AND HYDRAULICS. The C7000 Series is born to deliver impressive performance: with an extraordinary torque reserve, it takes peaks in engine loading easily in its stride. Durable and economical Mercedes Benz OM936 7,7 l engines produce 228 kW (310 HP) on 5 straw-walkers models and up to 280 kW (381 HP) on 6 straw-walkers models. With SCR technology with AdBlue®, all models offer very low fuel consumption figures. A large rotary screen cleans the cooling air fed to the radiators. Power is taken off on...

Ouvrir le catalogue en page 17

Easy access to all controls and settings during operation. OMMANDER STICK. C For controlling: 1) Position and inclination of header Ergonomic seat with mechanical or pneumatic adjustment and adjustable steering column for setting a comfortable driving position. ASSENGER SEAT. P Folds for optimal

Ouvrir le catalogue en page 18Tous les catalogues et fiches techniques (PDF) Deutz-Fahr

-

SÉRIE 5 DF/DS/DV ECOLINE.

4 Pages

-

SÉRIE 5 DF.

4 Pages

-

SÉRIE 5D TTV.

28 Pages

-

SÉRIE 6C.

48 Pages

-

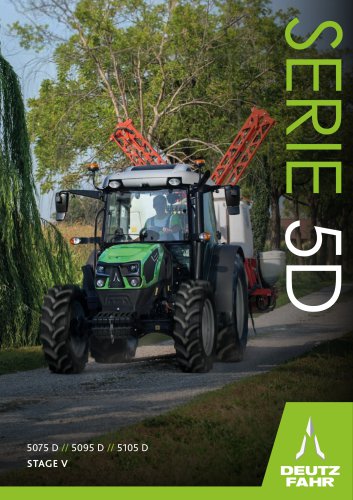

SÉRIE 5D.

4 Pages

-

GAMME 5DF KEYLINE

16 Pages

-

SÉRIE 5

32 Pages

-

SÉRIE C6000

14 Pages

-

SÉRIE C9000

48 Pages

-

SÉRIE C7000

16 Pages

-

5DS/5DV/5DF SÉRIE 5 DF ECOLINE

36 Pages

-

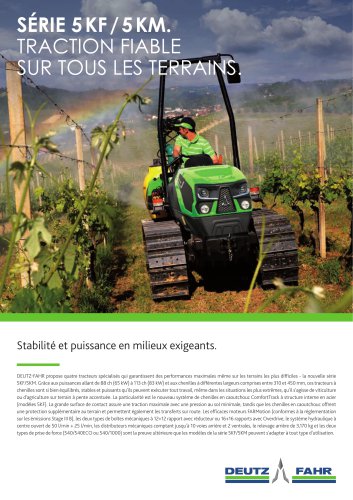

SÉRIE 5 KF / 5 KM.

2 Pages

-

5115 K.

2 Pages

-

SÉRIE 4E

20 Pages

-

SÉRIE 5D KEYLINE

20 Pages

-

SÉRIE 5G TB

16 Pages

-

SÉRIE 5G

32 Pages

-

2020 SÉRIE 6

36 Pages

-

SÉRIE 7 TTV

36 Pages

-

SÉRIES 7

36 Pages

-

SÉRIES 9

40 Pages

-

SERIES 5K

4 Pages

-

THE NEW 3 SERIES.

3 Pages

-

SERIES 6 TTV.

32 Pages

-

THE NEW 8280 TTV

32 Pages

-

SERIES 4E

16 Pages

-

5 SERIES

24 Pages

-

Agrokid

16 Pages

-

PRODUCT RANGE

48 Pages

-

Agrovector

12 Pages

-

Agrotron X 720

2 Pages