Extraits du catalogue

Tri-States Grain Conditioning, Inc. Grain Temperature Monitoring Systems

Ouvrir le catalogue en page 1

Grain Temperature Monitoring - An Effective Management Tool CONTROL ENERGY COSTS: 1 HP = 1 KW KW x (KW per hour) x KW per hour cost Example: 10 HP motor run for 14 days (14 days x 24 hours) @ 10¢/KW = $336.00 Your Operation: _____ x _______ x ___________ = __________ HP KW/hour KW/hour cost The following table can be used as a rule of thumb for warning signals: When grain is reading WARNING SIGNALS WARNING SIGNALS IMPORTANT: Any rapid rise of temperature in a given location in the grain mass - no matter how small - is an indication that trouble is developing. The greater the rise within a...

Ouvrir le catalogue en page 2

INITIAL COST PER BUSHEL TSGC markets a complete line of grain temperature monitoring systems to fit any size facility or budget and would be happy to provide you with a custom quote for your operation. The information below is for demonstration purposes only. 48’ Diameter x 33’ Eave x 48’ Peak - 53,000 Bushels 7,950 Bushels Direct Coverage Less than 1¢ per Bushel 3 Temperature Cables 50% Direct Coverage 7 Temperature Cables 100% Direct Coverage 1 Temperature Cable 15% Direct Coverage 26,500 Bushels Direct Coverage Less than 2¢ per Bushel 53,000 Bushels Direct Coverage Less than 4¢ per...

Ouvrir le catalogue en page 3

7 IMPORTANT REASONS WHY GRAIN MANAGERS USE TEMPERATURE MONITORING Maximum energy efficiency of aeration Helps keep grain in highest quality Detection of mold growth. Provides accurate information for safe, long term storage. Detection of insect activity. Alerts managers more quickly to changing Monitors the effectiveness of fumigation. grain conditions. TEMPERATURE MONITORING Temperature records help you, the grain manager, to react quickly to changes occurring within the grain. Whether grain is warm or cool, changes in temperature can be the first sign of potential problems....

Ouvrir le catalogue en page 4

THE IMPORTANCE OF GRAIN TEMPERATURE MONITORING Temperature is the key to safe grain storage. When grain goes out of condition, regardless of the cause, there is always an unusual increase in temperature. For those who manage grain, temperature is the best indicator of grain quality. Grain is a living organism. Like other living things, it breathes (respires) and it may become sick. Excessive moisture, high temperature, and poor grain condition (damaged kernels) are generally considered the most important factors that lead to trouble in stored grain. The three specific causes of heating are...

Ouvrir le catalogue en page 5

Natural Air Drying & Storage Equilibrium Moisture Content With increasing energy costs and the dry down capabilities of today’s hybrids, many producers are harvesting 16 to 20% corn. The following charts provide you with information on storage life and equilibrium moisture content for corn and soybeans. Grain Moisture Content will change with the relative humidity of the surrounding air. The following Equilibrium Moisture Values chart shows the relationship between the moisture content of corn at various temperature and relative humidity. Grain will deteriorate faster as temperature and...

Ouvrir le catalogue en page 6

Grain TRAC removes the guess work from grain storage. Grain TRAC reads and sends temperature data to a secure web page. Remotely read your Tri-States Grain Conditioning temperature cables from any computer with Internet access. Grain TRAC gives you the ability to monitor all your bins on a daily basis without driving, climbing or keeping hand written notes. ● Temperature cables that are installed in the bin connect to the Grain TRAC sensor board. ● Readings are taken 4 times daily to collect timely temperature data. ● The data is sent to the Internet...

Ouvrir le catalogue en page 7Tous les catalogues et fiches techniques (PDF) TSGC

-

MaxiScanTM 24

1 Pages

-

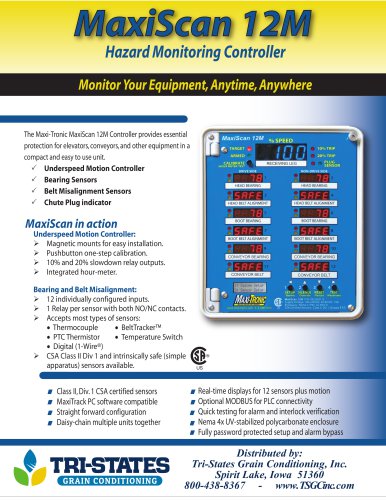

MaxiScan 12M

1 Pages

-

BEAR SCAN INFO

1 Pages

-

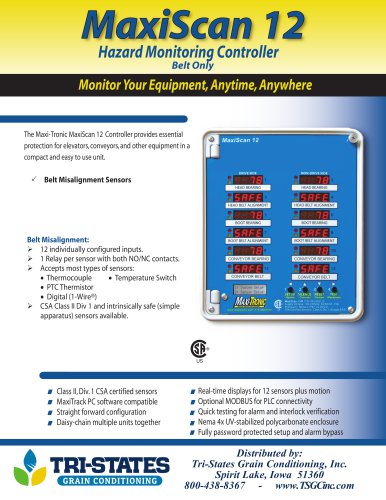

MAXISCAN INFO

1 Pages

-

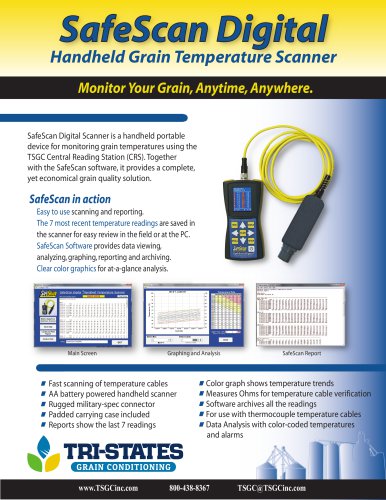

SafeScan

1 Pages

-

Bin Temp 612 & 1821

1 Pages

-

RS24 Remote Switch

1 Pages

-

PC3010

1 Pages

-

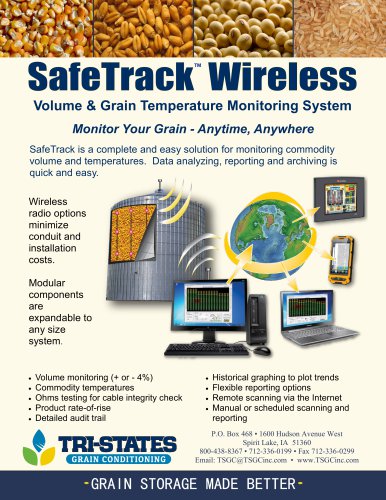

SafeTrack Wireless

1 Pages

-

GrainTrac

1 Pages

-

BTM

1 Pages