ウェブサイト:

Agroservis - proizvodnja d.o.o.

ウェブサイト:

Agroservis - proizvodnja d.o.o.

カタログの抜粋

HOW DOES BEDDY WORKS? Tilling section shreds, mixes and crumble soil, prepairing it for bed shaping operation. Soil containment elements (profilers) of the bed making section forms bed distributing loose soil prepared by tilling section of the machine.

カタログの3ページ目を開く

➢Easy handling ➢Robust construction ➢Trusted functionality ➢High performance ➢Reduces costs ➢High level of person

カタログの4ページ目を開く

MACHINE FEATURES ➢Fits machines with Cat 1 and 2, 3-Point hoop-up ➢Spiral placed blades results with lesser requirement for power and finest tilling ➢4 blades per flange (possibility for 6 blades per flange as additional option) ➢Adjustable working depth ➢Maximal working (tilling) depth

カタログの5ページ目を開く

MACHINE FEATURES ➢PTO shaft speed: 540 o/min ➢Shaft rotation speed: 238 o/min ➢Gearbox power - 48 kW ➢Power (driving) chain in oil bath ➢Possibility of performing only tilling operations – without bed making

カタログの6ページ目を開く

MACHINE FEATURES ➢Soil containment elements (profilers) makes bed by distributing soil prepared by tilling section of the machine. ➢Compaction of the soil in bed is enabled (and regulated) by spring system placed on upper part of the bed making secti

カタログの7ページ目を開く

BEDDY MACHINE MODEL

カタログの8ページ目を開く

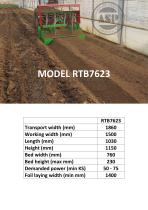

BEDDY MACHINE MODELS - PURPOSES Models of machines are derived according to the size of bed that each version of machine can create Intended (suggested) purpose of models: 1. RTB7618 - intended for single season plants 2. RTB7623 - intended for multi seasonal plants (e.g. strawberries)

カタログの9ページ目を開く

Transport width (mm) Working width (mm) Length (mm) Height (mm) Bed width (mm) Bed height (max mm) Demanded power (min KS) Foil laying width (min mm)

カタログの10ページ目を開く

Transport width (mm) Working width (mm) Length (mm) Height (mm) Bed width (mm) Bed height (max mm) Demanded power (min KS) Foil laying width (min mm)

カタログの11ページ目を開く

ADDITIONAL EQUIPMENT – FOIL LAYING SYSTEM ➢Removable and adaptable foil carrier that can recieve foil ➢Built-in mechanism that prevents unwanted unrolling of the f

カタログの12ページ目を開く

ADDITIONAL EQUIPMENT – ON GROUND IRRIGATION (DRIP) HOSE LAYING SET Allows laying up to 2 irrigation drip hose on ground (on previously formed bed) while foil is being layed. By using this set irrigation (drip) hose is placed between soil and foil that is being layed.

カタログの13ページ目を開く

Allows fertilisation of soil while bed is being created, meaning fertilizer is dropt on soil and buried during bed forming operations. Hopper is made of stainless steel. Dispersing is propelled by electromotor. Spreading quantity regulated by combination of setups on electric cabin control unit, mechanical regulator and tractor moving speed.

カタログの14ページ目を開く

ADDITIONAL EQUIPMENT – PUNCH WHEEL SYSTEM Main purpose is to punch holes on the layed foil in which plans will be transplanted. Zink coated/galvanized Depending of customer needs, system can contain 1 wheel (punching holes in 1 row), 2 wheels (punching holes in 2 rows) or even 3 wheels (punching holes in 3 rows).

カタログの15ページ目を開く

Klik ili scan za pregled • Machine is of European origi

カタログの16ページ目を開く

Address: Stjepan Radic street No. 136 33000 Virovitica R. Hrvatska / Croatia agroservisproizvodnja.vt@gmail.com agroservis.proizvodnja@vt.t-com.hr *All pictures and illustrations shown in this file are for illustration purpose only. Actual product may vary due to product enhancement.

カタログの17ページ目を開くAgroservis - proizvodnja d.o.o.のすべてのカタログと技術パンフレット

-

CULTSOY cultivator

10 ページ

-

CULTCOR cultivator

10 ページ

-

GADER weeder machine

10 ページ

-

HeKo Hemp harvester

11 ページ