カタログの抜粋

Kongskilde Dual Cleaner and Aspirators

カタログの1ページ目を開く

Kongskilde Aspirators FRL 10 blower can be used to vacuum off dust, for instance, on the discharge of grain driers or dust extraction spigot on elevators, augers etc. Aspirators are suitable for removing dust and light impurities from grain. grain to fall down into the bottom outlet of the aspirator. In an aspirator the grain passes through an upwards moving air stream. The dust and light impurities follow the air stream through the blower and on into a pipeline to the desired location for discharge. The air stream picks up dust and light impurities, whereas gravity allows the Cyclone for...

カタログの2ページ目を開く

KF 40 fitted with support legs. The construction of the pre-cleaner provides many options for integration in a grain plant: • Modular system for large flexibility for build-in solutions. • Easy access for regulation of the cleaning function, the regulation can be installed anywhere in the pipe line. Technical data Max. capacity (barley) t/h Motor size blower motor kW (HP) Air regulation for adjusting the suction power of the aspirator. • Installing the cleaner so the grain passes the cleaner both at the intake and outlet provides an optimal solution. Max. recommended conveying length for...

カタログの3ページ目を開く

Screens are easy fitted by means of quick release system. No tools required. Screen drum with 2 layers of screens. The Inner screen works as scalping screen retaining oversize impurities. The outer screen is a sand screen where small impurities are sorted from the prime product. KDC 4000 is a dual cleaner, with screen and aspirator function. The screens sort by means of size, in the aspirator unit light impurities and dust are removed by means of air. • Only rotation parts – no vibration transmitted, which reduces stress and wear on the components. • All components exposed to the ambient...

カタログの4ページ目を開く

The first bottom outlet can be opened, if you want to collect small kernels together with the screenings from the outer screen. KDC 4000 model with outlet hoppers, without auger. Ideal for cleaning crops with large impurities such as maize. Accessories: • Rain cover for gear motor on drum shaft and panel • Cleaning brush for outer screens. To be used when cleaning small seeds and size separation to avoid blocking the screens. • OK 200 pipes and cyclone for conveying the screenings for discharge up to 15m distance from the KDC4000. • Wide assortment of standard screens for all common crops....

カタログの5ページ目を開く

1 Intake 2 Inner screen 3 Outer screen 4 Auger 5 Screenings outlet 6 Fan 7 Venturi 8 Scoop elevating section 9 Aspiration chamber 10 Outlet, cleaned grain 11 Air bleed 12 Outlet from inner screen 13 Outlet for small grain, used e.g. when grading malting barley Mode of Operation 1. Inlet for unclean crop. 2. Inner screen separates the oversize impurities by retaining them. The conical shape of the screen drum slows down the grain, ensuring a good separation of the crop. 3. The outer screen sorts out the small impurities from the desired product, and also small kernels. 4. The screenings from...

カタログの6ページ目を開く

Screen selection for KDC 4000 combi-cleaner Inner screen Crop 1 2 3 Malting Rape Peas/ Barley barley Wheat Rye Oats seed Soya Maize Sun (sep.) Beans flower Perforation (mm) 1 Inner screens • The screens chosen determines the capacity for pre-cleaning. • Small holes provide a better separation of large impurities. • Large holes give a higher capacity. Choice of screens Choice of screens has a high impact on both cleaning capacity and efficiency. Max. cleaning (reduced capacity). Average cleaning (medium capacity). Pre-cleaning (high capacity). Outer screen Crop Malting Rape Peas/ Barley...

カタログの7ページ目を開く

drying tasks and heating in agriculture, construction and industry. Kongskilde was established in 1949, when mechanisation of agriculture began to be felt in Denmark. The company’s first products were cereal blowers, tine harrows and mobile heaters. The Kongskilde grain product programme includes: • Pneumatic transport • Mechanical transport • Cleaning and weighing • Drying • Storage • Complete system solutions • Measurement equipment and accessories • Heat sources - oil and gas heaters and electric heaters • Straw Drying These products, which at the time set new standards, still form the...

カタログの8ページ目を開くKONGSKILDE Industries A/Sのすべてのカタログと技術パンフレット

-

VIBRO SEEDER 6000

4 ページ

-

1-rotor rakes

8 ページ

-

Rotavator

6 ページ

-

Kongskilde Ploughs

28 ページ

-

Complete diet mixers

32 ページ

-

NS 1500 - 1900

2 ページ

-

Vibro Compact

4 ページ

-

Tedders

8 ページ

-

Front Terra C

2 ページ

-

SB4000/SB5200

4 ページ

-

Vibro Crop 2017

4 ページ

-

Clean cut 2021

20 ページ

-

VIBRO TILL 2900

8 ページ

-

COMBI JET

8 ページ

-

FLEXI DRILL

4 ページ

-

MULTI JET

8 ページ

-

KONGSKILDE TERRA-D

2 ページ

-

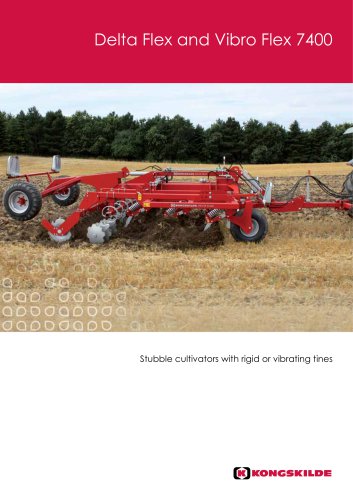

DELTA FLEX

8 ページ

-

VIBRO FLEX 7400

8 ページ

-

VIBRO TILL 2900 SF

8 ページ

-

VIBRO TILL 8200 SF

12 ページ

-

ÖVERUM CT-F

2 ページ

-

XLD PLOUGH BODY

5 ページ

-

KONGSKILDE MS-MT

2 ページ

-

VIBRO CROP VCR

2 ページ

-

KDC 8000

4 ページ

-

FAN GUARD

2 ページ

-

R+ 1610

8 ページ

-

R+ 2 ROTORS

8 ページ

カタログアーカイブ

-

Clean cut 2016

20 ページ