Website:

AGI

Website:

AGI

Catalog excerpts

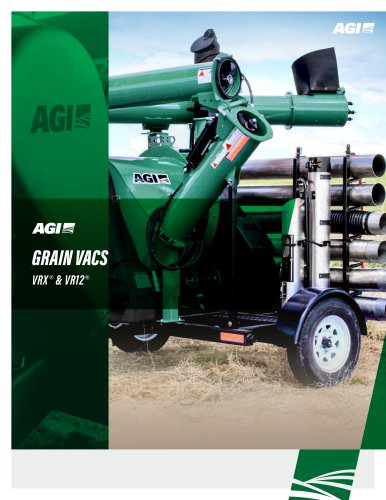

AGI GRAN VACS All aspects of AGI grain vacs are examined, questioned and tested, both individually and as part of the whole system, not just in controlled environments, but also in the field. By utilizing VR Technology ®, AGI grain vacs are able to get more capacity and longevity while reducing noise, debris and maintenance time. Signature body Specifically designed to minimize impact and maximize the auger feed - the drive shaft is mounted on the outside where you can access it. AGI grain vacs feature leak-proof cleanout doors with the ability to fully open without tools. Chrome augers AGI...

Open the catalog to page 2

The VRX sets the standard in grain vac technology and has capacity up to 6,000 BPH. The VRX sports 45-feet of 7-inch diameter hose. Combined with the telescoping inlet and the standing floor sweep, the VRX cleans up grain within a 49-foot radius from the base of the machine. The VR12 reaches up to 10,000 BPH with only 130 HP. The VR12 has 48-feet of 8-inch diameter hose. Combined with the telescoping inlet and the standing floor sweep, the VR12 cleans up grain within a 52-foot radius from the base of the machine. THE STANDARD HOSE PACKAGE INCLUDES: THE STANDHOSE PACKAGE INCLUDES: • One bin...

Open the catalog to page 3

HOSES & ACCESSORIES AGI grain vacs come equipped with more standard hose than any other. Together with the telescoping inlet and the standing floor sweep, the standard package cleans up grain within a 49 foot radius from the base of the machine with the VRX and a 52 foot radius with the VR12. To achieve the best capacity at any distance, cover much as possible with straight or smooth pieces like aluminum pipes and elbows, then add flexible portions like the stainless steel flex hoses and the bendahose where needed. Aluminum pipe Flex pipe Aluminum pipe provides the least resistance and...

Open the catalog to page 4

Transitions Transitions available in 4, 6, 7 and 8 inch sizes. 4" male to 7" male PART #: 38-10749 Durathane hose Durathane offers the most flexibility but is the least durable. 6" male to 7" female PART #: 38-104690 PART # 6" x 12' durathane hose without ends 7" x 8' durathane hose without ends 7" x 12 ½' durathane hose without ends 7" x 25' durathane hose without ends Cover is applied by holding the hose off the floor through 8 tighteners (6190-00-0128) or by a hose caddy. See hose caddy on the next page. 7” male to 6” female PART #: 38-103897 Hose cover (black) To help this lightweight...

Open the catalog to page 5

NOZZLES & SWEEPS Nozzles Clamps Clamps work best when sitting on top - not dragging beneath the hoses. 7" clean-up nozzle with wheels PART #: 38-108401 8" pull ring/clamp PART #: P2391-00-0002 8" clamp rubber seal PART #: P2391-00-0004 8" hose tightener 7" aluminum bin load-out nozzle 6" & 7" hose tightener 8” aluminum bin load-out nozzle PART #: 55-111828 *Use the bin load-out nozzle when you want to get maximum efficiency when loading out of a full bin Sweeps Use the floor sweep to clean up the bin floor in one swoop. This nozzle allows maximum efficiency when cleaning the bottom of a...

Open the catalog to page 6

Troubleshooting tips SHORT Position the grain vac as close to the source of the material as possible. Keep the length of piping short. The shorter the distance, the less piping friction and the greater the grain vac capacity. Drum brush kit for VR12 PART #: 45-113221 Drum brush kit for VRX PART #: 45-112996 Smooth pipes (interior walls) reduce resistance to air and grain movement. Where possible, use aluminum pipes first, then stainless steel flex pipes. Last of all use soft hose (for clean up only) as lightweight hose creates more friction. Drum brush kit for 552-2700 PART #: 38-104551 A...

Open the catalog to page 7

AGI is a global leader in supplying farm and commercial customers with the manufacturing, planning, and engineering of full equipment solutions for grain, seed, fertilizer, feed, and food. AGI’s expertise enables the storage, blending, mixing, conveying, conditioning, processing, and protection of agricultural products and inputs worldwide. Your safety is our highest priority. Please read and understand the operator’s manual and safety decals before using. Use and maintain products properly, and do not modify. Keep guards in place when operating and follow all product manuals and safety...

Open the catalog to page 8All AGI catalogs and technical brochures

-

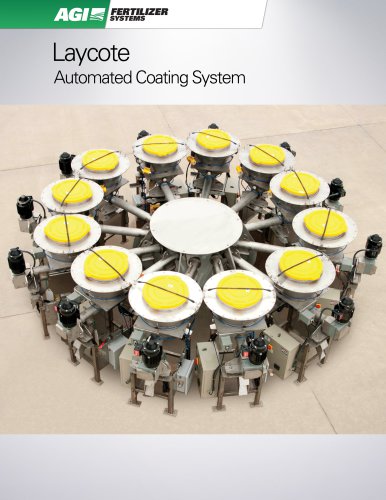

Automation Batch Blenders

2 Pages

-

FERTILIZER SYSTEMS

8 Pages

-

Conveying

2 Pages

-

AGI FRAME

31 Pages

-

AGI Handling Equipment

23 Pages

-

AGI Temporary Storage

4 Pages

-

AGI Bin Monitoring

16 Pages

-

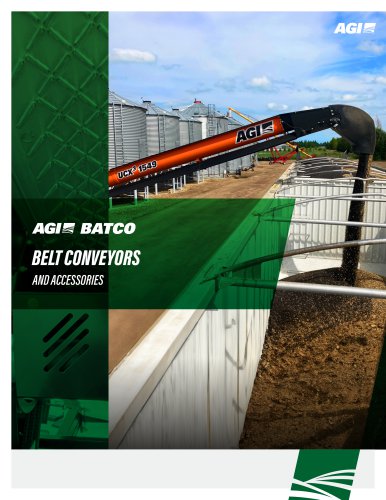

UCX3 Belt Conveyor

3 Pages

-

AGI Grain Storage

28 Pages

-

AGI Fertilizer Systems

8 Pages

-

AGI Structures

8 Pages

-

Aeration & Conditioning

7 Pages

-

Grain Processing Solutions

44 Pages

-

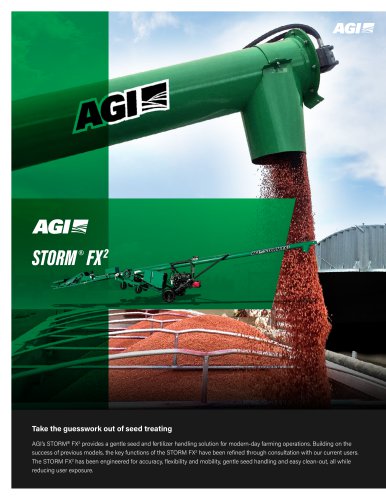

AGI Seed Treater FX2

2 Pages

-

AGI Post Pounder

4 Pages

-

AUGER TOOLS

4 Pages

-

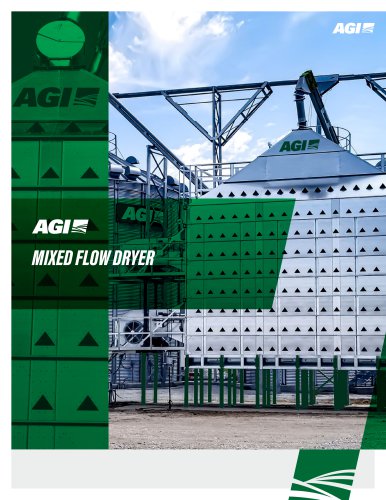

MIXED FLOW DRYER

8 Pages

-

Hutchinson Unload Systems

12 Pages

-

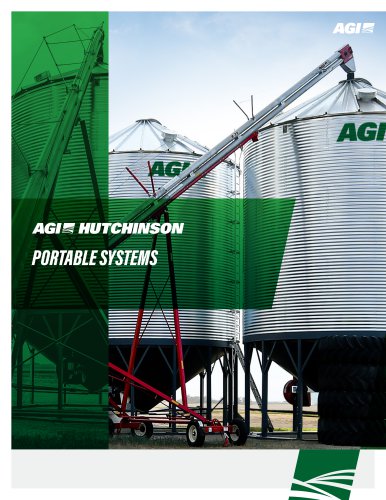

Hutchinson Portable Systems

8 Pages

Archived catalogs

-

AGI C-Line Permanent Handling

12 Pages

-

AGI Westeel Galvanized Storage

15 Pages

-

Westeel Petroleum Storage

11 Pages