Website:

AGI

Website:

AGI

Catalog excerpts

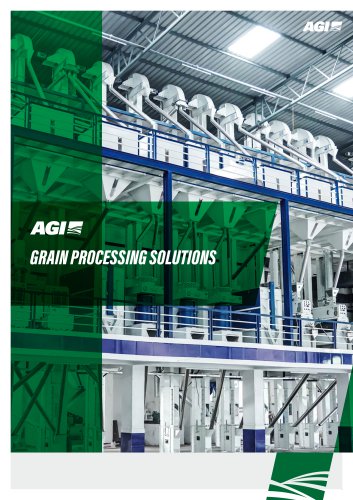

GRAIN PROCESSING SOLUTIONS

Open the catalog to page 1

Mission AGI is passionately committed to delivering innovative solutions to customers. Through qualitative and ethical practices, their equipment saves process losses and maintains hygienic standards in food processing and complimentary industries. Infrastructure AGI design centers are equipped with high-end servers and workstations complete with the latest CAD/CAM software and tools. Our state-of-the-art assembly shop, paint shop, and quality control division ensure only precision machineries leave our factory, meeting the exact requirements set from our clients. The service division is...

Open the catalog to page 2

Manufacturing Facility AGI Milltec® changed the Indian rice processing industry by producing top quality machinery locally, while following international quality standards. This resulted in the highest quality machine but at an affordable price. Following this quality and affordability model, AGI has made these rice milling solutions available to global customers. Manufacturing Capabilities Include: • Laser cutting Robotic MIG welding station

Open the catalog to page 3

AGI Rice Milling Product Portfolio AGI is the market leader in paddy processing and has commissioned more than 15,000 rice mills. Storage Silos Grain Silos Parboiling, Drying & Steam Generation Steam Generation Parboiling & Dryer Rice Processing Solutions Pulses Processing Solutions Color Sorting, Blending & Packing Solutions Packing AGI is the market leader offering complete end-to-end rice milling solutions for turnkey project implementation.

Open the catalog to page 4

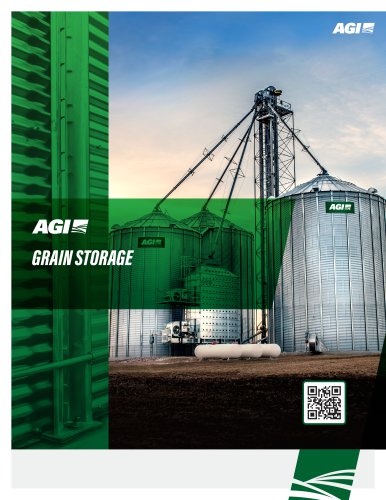

Storage Silos Grain storage silos are the best alternative for traditional storage systems. Our silos avoid storage losses like rodents, moisture, and insects. We design our silos based on the project requirements and provide ease of assembly, hygienic handling and use quality materials. AGI silos are made of high-quality steel and high-quality metal galvanized up to 600 GSM. We have highly qualified and experienced in-house engineers who provide the best service anywhere in the world. We have a dedicated project management team for every installation to ensure that installation is done...

Open the catalog to page 5

Packaged Boiler AGI offers fully automatic solid fuel fired steam boilers designed as per IBR (Indian Boiler Regulations) and has high thermal efficiency. • High thermal efficiency • Pneumatic over feed, three pass, wet back • Designed for ease of operation and hassle free maintenance • Multi-fuel: fire wood / coal / biomas / saw dust / wood chips / agro waste MA X OPER ATING PRESSURE FUEL CONSUMPTION (BASED ON 3,50 0KCAL / KG) TOTAL CONNECTED LOAD THERMAL EFFICIENCY (HE AT RECOVERY UNIT - HRU) Note: EXTERNAL WATER WALL BOILER is Supplied for Capacity above 5 tons/h

Open the catalog to page 6

Online Cooker Online Cooker is a steaming process which ensures uniform steaming of each and every paddy grain. Paddy will be given thermal treatment dependent on temperature and time. The gelatinized paddy is then thermally treated for a prescribed time, based on the clients desired color. This system produces quality rice for cooking, with less broken and minimal discoloration. The entire process is monitored and controlled by PLC. • Fully automated system monitored and controlled by PLC • Suitable for all paddy varieties • Best cooking and homogeneous color Application: Only paddy. •...

Open the catalog to page 7

Parboiling Parboiling is the process of hydrothermal treatment on paddy which is done in three steps: soaking, steaming and drying. Parboiling causes a gelatinization of starch during boiling, steaming and cooling, the amylase molecules re-associate with each other and forms tightly packed structure and mends the crack that developed in the endosperm. Parboiling increases grain translucency and hardness, decreases chalkiness, and is less sticky after cooking and reduces breakage. • Ergonomic design and convenient feeding and discharging system • Impeccable service, SS construction material...

Open the catalog to page 9

Fluidized Bed Dryer A continuous Fluidized Bed Dryer (FBD) system is used to reduce moisture from soaked paddy in a parboiling system. • Advanced design for high moisture reduction up to 5-6 % in single pass In FBD the wet paddy is conveyed over a perforated bed at the drying chamber. The system blows hot, ambient air through the holes of a perforated bed. The air blown will be passed through the wet paddy, behaving like a fluid and continue to flow until completely removing the moisture. Hence the name FBD. • FBD guarantees fast, continuous and homogeneous drying The air velocity is...

Open the catalog to page 10

Raw Paddy Dryer Paddy Dryers are used to reduce the moisture content in paddy grain for preventing spoilage during storage. • Simple construction and operation The harvested paddy will have a very high moisture level and may not be suitable for storing or milling directly. Hence the need to dry the paddy uniformly to the required moisture level of 14%. Various problems such as discoloration, loss of germination, mold development, insect infestation, odor development, loss of yield etc. can occur if not dried properly. • Stainless steel and mild steel construction • Ergonomic design,...

Open the catalog to page 11

Pulse Dryer AGI’s Pulse Dryer is designed to provide the best-in-the-class drying solution. This Fit-and-run equipment, with a compact design and a very less power requirement, provides the most economical drying while ensuring uniform and controlled drying for pulses (non-rice application). • Designed For Drying “full, round pulses”. • Highly efficient and power saving design. • Hygienic and user friendly equipment. • Suitable for handling all types of pulse applications. MA X CAPACIT Y ( TONNES PER BATCH) DRYING R ATE (% PER HOUR) FOR CHANA DRYING R ATE (% PER HOUR) FOR OTHERS High...

Open the catalog to page 12

Cyclonic Husk Furnace The Cyclonic Husk Furnace is an alternate source of hot air supply for dryers. The furnace produces clean hot air without smoke. It reduces energy costs by replacing an oil burner and gas fired furnaces. Cyclonic Husk Furnace is equipped with an automatic husk feeding and temperature controlled system. • High efficiency combustion produces clean hot air, smokeless, pollution-free and environmentally friendly Application: Husk only. • Digital temperature controller system provided with husk feeding system (auto controller) • 2/3 dryer can be connected with a single husk...

Open the catalog to page 13All AGI catalogs and technical brochures

-

Automation Batch Blenders

2 Pages

-

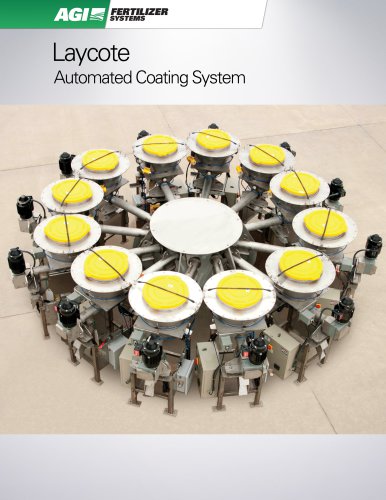

FERTILIZER SYSTEMS

8 Pages

-

Conveying

2 Pages

-

AGI FRAME

31 Pages

-

AGI Handling Equipment

23 Pages

-

AGI Temporary Storage

4 Pages

-

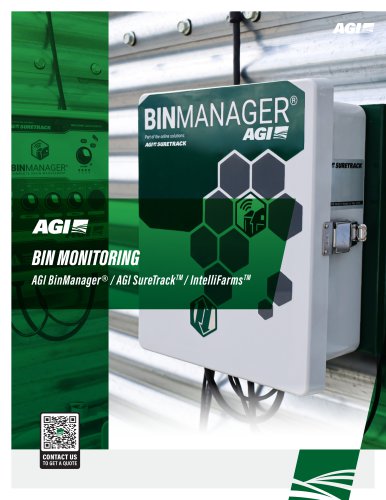

AGI Bin Monitoring

16 Pages

-

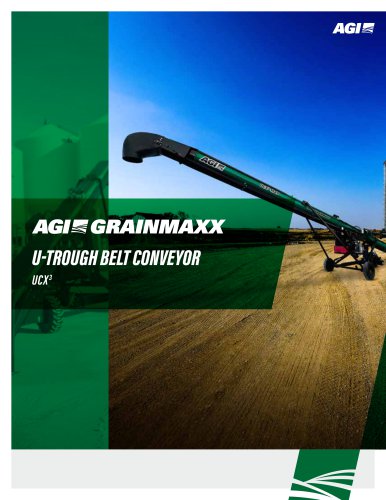

UCX3 Belt Conveyor

3 Pages

-

AGI Grain Storage

28 Pages

-

AGI Fertilizer Systems

8 Pages

-

AGI Structures

8 Pages

-

Aeration & Conditioning

7 Pages

-

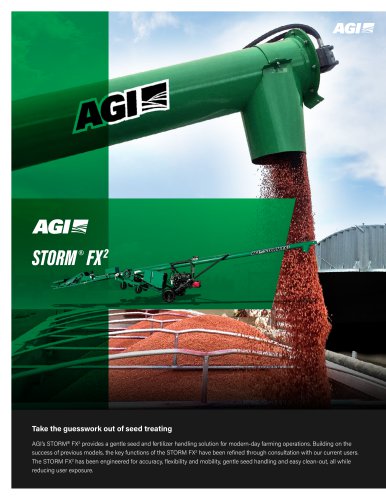

AGI Seed Treater FX2

2 Pages

-

AGI Grain Vacs

8 Pages

-

AGI Post Pounder

4 Pages

-

AUGER TOOLS

4 Pages

-

MIXED FLOW DRYER

8 Pages

-

Hutchinson Unload Systems

12 Pages

-

Hutchinson Portable Systems

8 Pages

Archived catalogs

-

AGI C-Line Permanent Handling

12 Pages

-

AGI Westeel Galvanized Storage

15 Pages

-

Westeel Petroleum Storage

11 Pages