Catalog excerpts

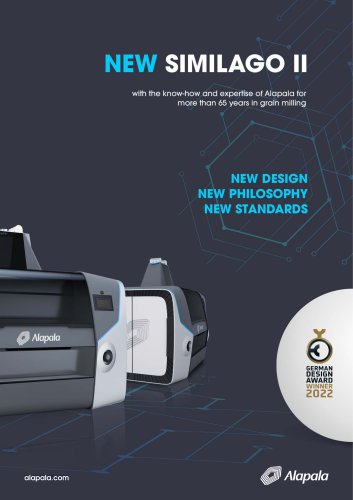

NEW SIMILAGO II Designed to meet the future’s expectations NEW SIMILAGO II Roller Mill is the result of know-how and expertise of Alapala for more than 65 years in grain milling. New standards in reliability, efficiency, and sanitation, but that’s not all… NEW SIMILAGO II roller mill is also ready to meet the future’s expectations from today with its digital innovat

Open the catalog to page 3

perfect evolution of a new design and technology While we have entered through the digital era in industry, we created NEW SIMILAGO II roller mill which stands out with a new futuristic design, technology, and an improved functionality for its users. The roller mill’s industrial design development process has been carried out in the collaboration of Alapala R&D team with ITALDESIGN. Moreover implementing digital technologies into milling, NEW SIMILAGO II roller mill’s technological foundations are now ready to incorporate with next generation’s milling systems.

Open the catalog to page 4

Ultimate Grinding NEW SIMILAGO II is equipped with high technology electronic control systems for a continuous and consistent performance in the grinding of cereals, such as wheat, maize (corn), rye, spelt, barley and sorghum.

Open the catalog to page 6

Feeding Control Systems Stock Level Control The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly. Feed Roll Speed Monitoring Rotational speed of feed rolls is monitored against an unexpected stop due to belt problem, etc. Feeding Gap Adjustment Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls. Grinding Control Systems Motor Load Monitoring Main motor load is constantly measured for protection against any possible damage. Main Roll Speed Monitoring The rotational speed of...

Open the catalog to page 7

NEW SIMILAGO II is built to comply with the high sanitation standards and ensure food safety. safe food processing. The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk. Stainless steel product contact surfaces is also available as an option. Time Saving Solutions. Quick Roll Change Roll change operation can be performed in just 20 minutes, with is a significant reduction in down times. Also, the operation can be carried out easily with only using a standard tool set. Central Lubrication System The system allows one-point and automatic...

Open the catalog to page 8

Variants • 800 mm, 1.000 mm or 1.250 mm roll length • 250 mm (standard) or 300 mm roll diameter • Double Deck version to save from space • Direct Pick-Up Version Accessories • Main drive motor, incl. pulleys and belts * • Motor mounting profile beams and fasteners * • Electrical motor trays * • Floor mount metal chassis incl. anchor bolts * • Roll disassembly trolley incl. toolbox * • Pulley and bearings disassembly set * • Discharge hoppers (*) Only supplied as standard in turnkey projects Options • Stainless Steel Contact Surfaces • Semi Automatic Roll Gap Adjustment • C

Open the catalog to page 10

Front View Side View TECHNICAL FEATURES Feed Roll Motor (kW) DISCLAIMER: Alapala Dış Ticaret San. ve Tic. A.Ş., believes the specifications in this brochure to be correct at the time of printing. However, specifications, standard equipment, options, and colors are subject to change without notice. Some equipment may be unavailable when your machinery is built. Please ask your sales representative for advice concerning current availability of standard and optional equipment, and your sales representative will verify that your machinery will include the equipment you ordered. Some of the...

Open the catalog to page 11

Alapala B.V. Rivium Quadrant 175, 2909LC Capelle aan den ljssel / The Netherlands Alapala Foreign Trade Ltd. Yeşilköy Mah. Atatürk Cad. EGS Business Park Blokları B - 3 Blok Kat: 14 No: 431, 34149 Bakırköy, İstanbul / Turkey Alapala Machine Inc. Organize Sanayi Bölgesi 12. Cadde No:18 PK54 19040 Çorum / Turkey +90 (212) 465 60 40

Open the catalog to page 12All Alapala catalogs and technical brochures

-

SIMILAGO II

16 Pages

-

Products & Technical Catalogue

164 Pages

-

AURORA MODULAR PLANSIFTER

16 Pages

-

GRAIN STORAGE & HANDLING SYSTEMS

17 Pages