Catalog excerpts

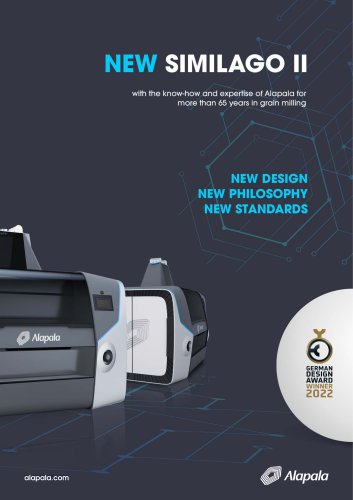

a perfect evolution of technology Similago II New Ideas – New Thinking – New Generatio

Open the catalog to page 2

REVOLUTION IN MILLING TECHNOLOGY GOES ON... Stainless steel contact parts

Open the catalog to page 4

The new SIMILAGO II is the result of ALAPALA’s 60 years of experience in the technology and engineering of roller mills and the complete range of milling machinery. The SIMILAGO II is designed for high, continuous and consistent grinding of cereals such as wheat, maize (corn), rye, spelt, barley and sorghum. A uniform feed rate across the grinding rolls ensures a consistent grind. Structurally, the SIMILAGO II has a sturdy frame which is a desk type, precision machined by using the most modern CNC machines. The steel used is a special quality high carbon steel. The bearings and the grinding...

Open the catalog to page 5

Easy and fast change of the rolls can be performed in 20 minutes, which is a significant reduction in down times. No special tools are required as the standard tools can be used. No lifting devices for the roll sets are required as they can be dismounted directly from the machine onto a cart. The grinding rolls are mounted on self-aligning double row roller bearings which are housed in 25 mm thickness housing. For inspection purposes, double walled inspection door (Alapala design) which can be opened and closed easily due to a weight system avoiding the use of latches. This enables the...

Open the catalog to page 6

20* MINUTES CHANGE SO MANY THINGS * The disassembling of a roller set and the assembling of a new roller set are performed in 20 minutes, so the downtime of the milling section is minimized with Similago II.

Open the catalog to page 7

The feed roll speed is controlled automatically by the capacitance sensor in the feed box which sends a signal to feed roll drive motor invertor via a PLC according to the product level in the feed box. No calibration is required. This ensures a perfect and uniform product feed to the grinding rolls. The polycarbonate inspection glass on the feed box can be easily removed from the outside without the need to dismantle the feed spouts and related parts, for cleaning.

Open the catalog to page 8

The SIMILAGO II complies with the sanitation standards. Opportunity for maximum cleaning and hygiene in a few minutes by setting lower chamber of feeding system rollers to fully open position with only a single operation.

Open the catalog to page 9

A user friendly touch screen operator interface panel between the operator and microprocessor which is mounted on both sides allows the continuous and changing and monitoring of all the operating parameters together with alarms and graphical system visualisation. This allows easy speed changes, product level in the hopper, motor power consumption, alarm e.t.c. The system comes with a built in RS 485 interface for communication. An optional Profibus module can be installed for net working with the main mill PLC. For safety an emergency stop buttons are installed. The machine is supplied...

Open the catalog to page 11

Nature’s blessing inspires our innovations...

Open the catalog to page 13

PRODUCT INLET PRODUCT INLET MATERIAL INLET LEVEL SWITCHES HANDGRIP SHUT-OFF VALVE øJ FINE ADJUSTMENT GROUP FEED ROLLS GRINDIG ROLLS MATERIAL OUTLET AIR SUCKING BREAK PASSAGES REDUCTION PASSAGES Dimensions [mm] Model DAVS II 4 x ø 250 / 800 DAVS II 4 x ø 250 / 1000 DAVS II 4 x ø 250 / 1250 DAVS II 8 x ø 250 / 800 DAVS II 8 x ø 250 / 1000 DAVS II 8 x ø 250 / 1250 DAVS II 4 x ø 300 / 1250 DAVS II 8 x ø 300 / 1250

Open the catalog to page 14

Standard Accessories Lifting hooks Discharge hoppers Optional accessories Main drive motor, drive belts and pulleys Motor mounting profile beam and fasteners Adjustable motor mounting Floor mount metal chassis with anchor bolts* Roll disassembly & assembly cart* All required tools* Wrench set* Optional accessories marked (*) are supplied as standard accessories for complete turnkey projects.

Open the catalog to page 15

ALAPALA’S NEW STATE OF THE ART MILLING TECHNOLOGY. pusula reklamevi New Generation Similago II provides more energy efficiency and helps to save nature for future. “Passion for milling since 1954” HEADQUARTERS & FACTORY : ORGANİZE SANAYİ BÖLGESİ, 12.CADDE NO: 15 PK.54 19040 ÇORUM, TURKEY SALES & MARKETING www.alapala.com • www.alapalaworld.com

Open the catalog to page 16All Alapala catalogs and technical brochures

-

Products & Technical Catalogue

164 Pages

-

AURORA MODULAR PLANSIFTER

16 Pages

-

GRAIN STORAGE & HANDLING SYSTEMS

17 Pages

-

NEW SIMILAGO II

12 Pages