Catalog excerpts

PELLET PRESS ALTINBILEK Pellet Presses are designed based on "Quality, User Satisfaction, Environment and Nature Consciousness". Pellet Presses are machines which, after mixing the powdered raw materials or mixed powder products with steam and / or water in certain proportions enables it to be formed into pellets of various diameters (Ø1,6-22 mm) by mechanically compressing and passing through the perforated molds called discs with the help of roller-shaped pressure rollers. When used in the production of feed, Pellet Press prevents the decomposition that often occurs in the powder product depending on the transportation, storage, environmental conditions and the ability of the animals to choose; the prepared ration is maintained within the desired homogeneity balance, facilitates the digestion of the animals, thus increasing the desired yield from the animal. It enables the death of harmful microorganisms and increase hygiene due to the heat generated by the compression. The density of powder raw materials or products that are brought into pellet form is increasing. Compared to powdered products, the storage and transportation costs of pelleted products are reduced, losses are prevented, shelf life increases and becomes more economical under appropriate storage conditions. Pellet Presses have effective usage areas outside the feed industry. It is used to pellet raw materials and wastes such as bran, pulp, various grain husks, corn stalks, wood chips, garbage, organic fertilizers, hops and pomace. FEATURES Reinforced Structure High Strength Special Circular Design Double Piece Body That Makes Carrying Easy Special Design Stainless Cover and Pelletizing Cubicle Regular Ampere Draw in One Engine with Balanced and Equal Supply Large Pelletizing Surface Area High PDI (Pellet Durability Index) Values in the Product Superior Capacity Performance High Production Capacity Short Downtime Heavy Type Block Bearings Easy Use and Maintenance DRIVE SYSTEM IE3 Class High Efficiency Electric Motor (IE4 - Optional) Possibility for the motor to be mounted on the right or left side Belt-Pulley Connection Power Transmission SECURITY SYSTEM Electro-Pneumatic Controlled Magnet Separation System Safety Pin and Safety Sensor to Prevent Damage to the Machine in Case of Sudden Jamming Electro-Pneumatic Controlled By-Pass System Special Coupling System that Protects the Engine in Sudden Jamming Safety Sensor on the Cover Electromechanical Lock System (Optional) Roller Temperature Detection (Optional) ACCESSORIES High attraction magnet Cutting Blades Providing the Possibility of Adjusting the Length of the Product Inlet and Outlet Sampling Compartments Electric Winch System that Shortens the Change Time of Dies and Rollers, Provides Forward-Backward and Down-Up Movement Opportunity Reinforced Bearing - Roller System High Efficiency Powerful Motor Options High Permeability Close Hole Die Rollers Suitable for Raw Material (Channel and / or Perforated Type) Slowed Disk Rotation System (Optional) That Makes Operation Safe and Easier while in Maintenance Clamped or Forehead Mounted Disc Holding System (Optional) Automatic Lubrication System (Optional) Automatic Rolling System (Optional) Vibration Absorbing Rubber Wedges Closed Type Casing www.abms.co

Open the catalog to page 1

PELLET PRESS Rule Rule Adedi Çapı(mm) İç Çap Genişlik Alan (mm) (mm) (cm2) The designs and dimensions may be modified without notice.

Open the catalog to page 2All ALTINBILEK GRAIN HANDLING AND STORAGE SYSTEMS catalogs and technical brochures

-

TWO-WAY VALVE

8 Pages

-

BUCKET Z ELEVATOR

2 Pages

-

FLAT BOTTOM SILOS

15 Pages

-

HOPPER BOTTOM SILOS

5 Pages

-

SCREW CONVEYOR UH150-200-250

2 Pages

-

LOADING BELLOW

3 Pages

-

SEPARATOR

1 Pages

-

HAMMER MILL

2 Pages

-

MIXER

2 Pages

-

ROTARY DRUM SIEVE

2 Pages

-

Flour Silos

6 Pages

-

Intake Pit Dust Aspiration

4 Pages

-

Corn Drying Systems

6 Pages

-

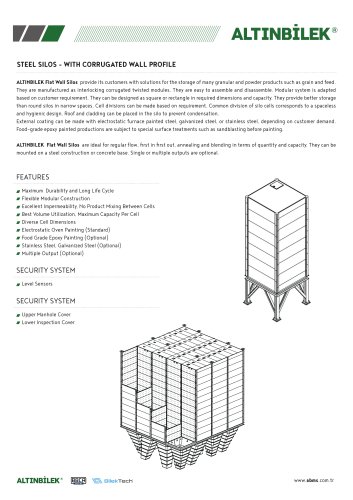

Square Silo

6 Pages

-

Rotary Drum

6 Pages

-

Bottom Scraper

4 Pages

-

Steel Silos

16 Pages

-

Abcordion

4 Pages

-

BBCA Catalog

56 Pages