Catalog excerpts

AERODYNAMIC SEPARATORS Agricultural Science and Technology Co.

Open the catalog to page 1

SEPARATORS - WHAT THEY ARE AND WHERE THEY ARE USED We would like to present to you the developed and manufactured by us specialist equipment for grain cleaning and separation - the ASM brand aerodynamic separators. They use a patented technology for cleaning and segregating output material on the basis of specific weight by means of appropriately directed air streams. ASM separators are used for efficient grain cleaning and calibration. They can work with any material (cereal grains, grass grains, legumes and oil plants), irrespective of its moisture content.

Open the catalog to page 2

food industry during the cleaning and separation of seeds for sowing material it is possible to select the most biologically valuable seeds, which translates into an increase in yields of up to 40%! the pre-cleaning and cleaning mode allows the grain to be prepared for storage (improved phytosanitary properties) and the post-drying function allows the humidity of the grain to be reduced to ensure the right conditions for storage various modes of separator operation allow effective cleaning of different types of raw materials for mills, groat mills, feed factories, oil mills, distilleries,...

Open the catalog to page 3

Seed calibration basing on specific weight METHOD OF OPERATION The separator divides the raw material according to its specific weight. Separation takes place using air streams and divides the material into fractions (from the heaviest to the lightest). This makes it possible both to clean the raw material of impurities and to sort it into various types of material (e.g. seed, consumer grain, feed grain, waste). Moreover, thanks to the difference in weight, the separator separates infected material and removes pests. The ASM aerodynamic separator separates any material of a certain density...

Open the catalog to page 4

PATENTS The method of grain separation was described in the patent application PCT/UA2016/000030, publication number WO2016195615. On its basis we have obtained the patent protection in the USA and China (the procedure in the EU is in progress). Additionally, we have a reservation of industrial designs of the manufactured models.

Open the catalog to page 5

STARTING MATERIAL The machine works well with all types of grain. Starting from grass seeds, through cereals, oil plants and legumes. STARTING MATERIAL STARTING MATERIAL STARTING MATERIAL STARTING MATERIAL FRACTION GERMINATION, % In addition, the cleaning process itself reduces the humidity of the raw material by separating green impurities. It makes it possible to clean highly contaminated raw material, as well as material with a high level of humidity. It perfectly works with the material both before and after drying. STARTING MATERIAL STARTING MATERIAL FRACTION GERMINATION, % STARTING...

Open the catalog to page 6

DIVISION INTO FACTIONS During operation, the separator divides the source material into 5 fractions: Fraction I – heavy impurities Fraction II and III – best-growing grain Fraction IV – fine grain, half-grains Fraction V – light impurities Cyclone – dust, dirt Depending on the quality of the raw material and the user’s needs, we can regulate the quality and quantity of the material going into the individual fractions. We can also combine individual fractions with each other (e.g. waste from fractions I and V, good material from fractions II-I

Open the catalog to page 7

MODES OF OPERATION Depending on the needs, the machine can operate in different modes with different capacities: high efficiency pre-cleaning medium-efficiency fine cleaning separation (calibration) with low efficiency which removes the extreme fractions (heavy and light impurities) and will enable the raw material to be divided before storage (e.g. into consumer grain and fodder grain). This will prepare the raw material for storage and/or drying (using material from fractions II-IV after pre-cleaning), allowing for removal of impurities and precise division of raw material into fractions...

Open the catalog to page 9

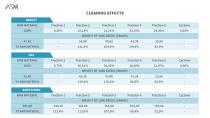

CLEANING EFFECTS The separator copes perfectly with different types of raw material. Examples of pre-cleaning: WHEAT RAW MATERIAL WEIGHT OF 1000 SEEDS (GRAMS) 33,20 WEIGHT OF 1000 SEEDS (GRAMS) 33,62

Open the catalog to page 10

CLEANING EFFECTS BARLEY RAW MATERIAL WEIGHT OF 1000 SEEDS (GRAMS) 47,42 WEIGHT OF 1000 SEEDS (GRAMS) 33,62 WEIGHT OF 1000 SEEDS (GRAMS) 291,08

Open the catalog to page 11

EFFECTS OF THOROUGH CLEANING GERMINATION CAPACITY GERMINATION ENERGY GERMINATION CAPACITY GERMINATION ENERGY GERMINATION CAPACITY GERMINATION CAPACITY GERMINATION ENERGY GERMINATION ENERGY

Open the catalog to page 12

WHITE MUSTARD SEED QUINTUS WHEAT Raw material Organic pollutants Organic pollutants Abnormal crops Abnormal crops Organic pollutants Abnormal crops

Open the catalog to page 13

BENEFITS IN CASH – PRE-CLEANING Pre-cleaning performed immediately after harvesting allows to: remove impurities, thus reducing the amount of material for drying - approx. by 5% reduce the moisture content of the raw material before drying by approx. 2% (for wheat) This translates into the savings as specified below: WHEAT Raw material Weight Moisture Cost of drying After cleaning It has been assumed that lowering the moisture content of 1t of grain by 1% (1 t/%) requires the use of approx. 2 litres of fuel oil (the cost of electricity and labour has not been taken into account). raw...

Open the catalog to page 14

CORN Raw material Weight Moisture Cost of drying After cleaning In the case of corn, pre-cleaning allows for greater moisture reduction (on average fractions II and III have a moisture content lower by 4 to 6% compared to the raw material). This translates into a higher amount of green waste. Cost of drying: raw material – 1 tonne * 16 t/% * 2 litres * 1,00 € = 32,00 € material after cleaning – 0.9 tonne * 12 t/% * 2 litres * 1,0

Open the catalog to page 15

SAVINGS - SEEDS Separation allows to select the best material for sowing, with similar germination capacity. For example, in the case of non-separated wheat with a germination capacity of 96% after 14 days, the germination capacity after 7 days was 80%. For separated seeds, these values were 96% and 92%, respectively. This translates into an uniform grain maturation process during the harvesting period. In the case of standard seeds, at harvest time about 80% of grain was ripe and ready to be harvested, while the remaining 20% consisted of unripe or overripe ears. The separation process in...

Open the catalog to page 16