Catalog excerpts

Reactor tanks for biogas

Open the catalog to page 1

Biogas tanks from Assentoft Silo A/S Assentoft Silo supplies biogas reactor and storage tanks made from bolted steel plates, insulated, if required. Twenty-five years of experience in biogas projects and other major industrial projects throughout Europe makes Assentoft Silo an attractive partner, providing active coaching and help in designing your complete system. Design of your biogas plant In the tender and design phase, we prepare 3D drawings and films to illustrate the plant. We often perform many versions of a plant, before the final design is determined. We help designing the plant...

Open the catalog to page 2

Choosing the right reactor tank Assentoft Silo’s reactor tanks provide maximum flexibility in: ■ Selection and composition of materials - glass enameled, stainless steel, epoxy coated or galvanized steel sheets - as well as a choice between insulated steel roof or membrane roof. ■ Sizes from 500 m³ to 7,000 m³ with optional combination of height and diameter. ■ Suitable for center stirrer, side mounted stirrer and gasmix. ■ Used as both primary and secondary reactor vessels and storage tanks. ■ Minimization of heat loss by effectively insulation of the tank wall and the roof. Documentation...

Open the catalog to page 3

Help calculating operating and construction costs for a plant In collaboration with the two leading manufacturers of insulation, Assentoft Silo has developed a calculation of heat losses in the steel and concrete reactor tanks. To be used when comparing total costs for a project. Comparison of a 4030 m³ steel tank and a 4020 m³ concrete tank Enter the following Steel reactor tank Concrete reactor tank Interest rate The cost of the tank is amortirized over Hight - tank wall Insulation thickness: roof Insulation thickness: wall Insulation thickness: foundation Tank price incl. insulation,...

Open the catalog to page 4

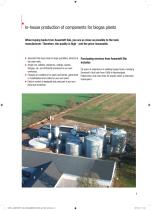

In-house production of components for biogas plants When buying tanks from Assentoft Silo, you are as close as possible to the tank manufacturer. Therefore, the quality is high - and the price reasonable. ■ ssentoft Silo buys steel in large quantities, directly at A the steel mills. ■ ngle iron, ladders, platforms, railings, spools, A flanges, etc. are efficiently produced in our own workshop. ■ langes are welded on to pipes and bends, galvanized F or sandblasted and coated on our own plant. ■ lectric control is designed and produced in our own E electrical workshop. Purchasing services...

Open the catalog to page 5

Piping Pipes, bends, spools etc. of any size can be supplied according to customer requirements Produced, sandblasted and coated at our factory in North Jutland. Control panels for controlling biogas plants We have a large production of electric control panels for our silo plants, also for industrial purposes and biogas. Our electric control panels are made with PLC and touch screen for management and monitoring of the biogas plant. Including connection to analog and digital input signals and perhaps connection to the internet for external monitoring and service. We can also offer GSM based...

Open the catalog to page 6

Assentoft Silo secures a satisfying result that lasts! - 500 industrial projects and 4,000 farm silo projects throughout Europe is the proof. Reactor tanks from Assentoft Silo are designed for 30 years of operation. Standard operating pressure in a steel tank is 0.03 mbar or 300 mm water column, which moves the gas on in the process without a gas blower. The tanks are suitable for both thermophilic and mesophilic operation - or switching between the two types. Tanks, where the diameter and height corresponds to each other, is less expensive to stir, and it is easier to obtain an effective...

Open the catalog to page 7

In Denmark and other European countries, Assentoft Silo delivers effective and reliable project management Assentoft Silo provides complete tank or silo solutions also for storage of grain, maize kernel, cement, sand, bitumen, fish oil etc. In addition we act as subcontractor of tanks and silos for leading Danish suppliers of e.g. concrete plants, asphalt plants and flue gas cleaning filters. 3.300 m3 silo for cement delivered in France, 2009. 8

Open the catalog to page 8

Diam. Diam Volume in the silo shell m³ m Section from size chart with tanks

Open the catalog to page 9

All-welded silos and tanks Rational storage and handling of dry products/residues and liquid raw materials for biogas production. Welded tanks and silos from 10 m³ and up to 150 m³, designed, produced and supplied on site. On our own factory in North Jutland 15 certified welders produce tanks, silos and piping systems. The tanks are sandblasted and epoxy treated in our own paint shop and insulated, if required by customer. The tanks are made as standard products – with the possibility of equipping after customer demand. Diameters from 2546 to 4500 mm.

Open the catalog to page 10

Example of equipment on an all-welded silo WAM SILO TOP FILTER WITH FILTER FLANGE ALUMINIUM ACCESS HATCH POSITIVE/NEGATIVE PRESSURE VALVE ROOF RAILING WELDED LADDER LEVEL INDICATOR STEEL ACCESS HATCH CONE WITH VIBRATION BOTTOMH DAMPER (TURNABLE) LIME AUGER CAPACITIVE SENSOR CONTROL PANEL SILO WALL TO GROUND WITH DOOR

Open the catalog to page 11All Assentoft Silo catalogs and technical brochures

-

S1500 og 2000

49 Pages

-

T 207

49 Pages

-

S 1000

42 Pages

-

Sealed storage

16 Pages