Catalog excerpts

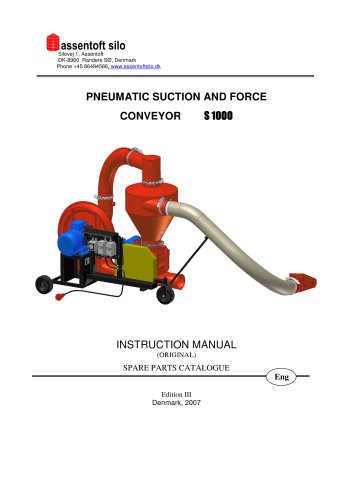

Silovej 1, Assentoft DK-8960 Randers SØ, Denmark Phone +45 86494566, www.assentoftsilo.dk PNEUMATIC SUCTION AND FORCE CONVEYOR INSTRUCTION MANUAL (ORIGINAL) SPARE PARTS CATALOGUE Eng Edition III Denmark, 2007

Open the catalog to page 1

PNEUMATIC SUCTION AND FORCE CONVEYOR S 1000 (DIAMETER OF PIPELINE 160 mm) INSTRUCTION MANUAL SPARE PARTS CATALOGUE Serial number ……………. Year of production …………….

Open the catalog to page 3

2. WARNING AND INFORMATION GRAPHICS 8. WORK WITH THE CONVEYOR 9. WORK IN SUCTION AND FORCE SYSTEM 10. WORK IN FORCE SYSTEM 14. DISMANTLING AND DEMOLITION INSTRUCTIONS 15. STANDARD OUTFIT FOR SALE, TRANSPORT 16. RESIDUAL RISK DESCRIPTION SPARE PARTS CATALOGUE WARRANTY CONDITIONS

Open the catalog to page 4

INTRODUCTION Instruction manual belongs to the standard outfit of the machine. In case the machine is sold again, this instruction manual must be given to the end-user. This instruction manual must be read and followed by all personnel using, setting up or servicing the machine. Following the guidelines included into the present manual will guarantee nonfailure work and effective use of the machine. Identification details can be found on data plate attached to the conveyor’s framework. In case of any doubts or incomprehension of text herein, contact the producer of the machine, i.e.:...

Open the catalog to page 5

ATTENTION ! 1. When operating the machine in a humid room or area always use watertight cables, plugs and sockets which enable applying neutralization or earthing. 2. In case of long non-exploitation, check connections of neutral conductor in plugs and sockets before reusing the machine. 1. INSTRUCTIONS FOR A SAFE USE 1. Carefully read through the complete instruction manual before using the machine for the first time. 2. Before starting the conveyor, check condition of the machine with regard to the instructions for a safe use. 3. The conveyor must be used only by an adult person who is...

Open the catalog to page 6

WARNING AND INFORMATION GRAPHICS Safety signs and information labels are placed on conveyor according to Fig. 1. Table 1 includes list and description of the signs. Safety signs and information symbols must be clean, clear and protected from damage, getting painted or coming unstuck. Damaged, illegible or missing labels must be renewed. The labels are provided by the producer on request after giving a code of a sign which is included in the Table 1. Fig. 1. Location of information signs and warning labels on conveyor S 1000.

Open the catalog to page 7

Table 1. Warning signs and information symbols 1. 2. 3. Emplacement of the machine read the instruction manual, chilldren are not allowed to operate the machine, do not connect the machine to the mains in case of the failure of connection unit and socket, use proper connections /socket, plug, electrical cord/ of tested effectiveness against electric shock, disconnect the machine from the mains before any repair. Sign code The housing of belt transmission Danger of retracting – belt transmission. Do not open and remove the protection housing whilst the machine in motion. The housing of chain...

Open the catalog to page 9

CAUTION ! IT IS FORBIDDEN TO: 1. work without the protection housing of the belt and chain transmission or with damaged housing; 2. look in the end pipeline outlet whilst machine in motion; 3. operate the conveyor by an unauthorized person, bystander, a person under influence of alcohol or drugs and specially by a minor. The pneumatic suction and force conveyor S 1000 is used for transporting popular grain, maize, seeds of leguminous plants or oil seeds. It is suitable for loading grain from means of transport into granaries and inversely; it can be used for filling up silos and bins as...

Open the catalog to page 10

4. TECHNICAL FEATURES Symbol of conveyor Performance Max transportation length Max transportation height Diameter of transportation pipe Fan – t ype Rotational speed Air flow rate Total pressure Electric engine – type Power Rotational speed Supply voltage Rated current Feeder – type Diameter Number of chambers Rotational speed Feeder electric engine – type Power Rotational speed Supply voltage Rated current Dimensions: Length Width Height Weight Noise level Operation t/h m m mm rev/min m3/h Pa kW rev/min V A mm pc. rev/min Operating parameters of S 1000 in suction and force version Fig. 2....

Open the catalog to page 11

Height of transportation H = 3m Length of transportation L(m) Performance (t/h) ATTENTION ! – figures given in the tables are approximate and concern wheat of 700 kg/m3 specific gravity, humidity up to 14% and dirt to 1%. The values are comparable for grain of barley and maize. Increase in humidity or dirt of grain may cause decrease of performance up to 20%. The performance of the conveyor depends on length and height of transport pipeline as well as a kind and features of transported grain (moisture, dirt level). The total transport length equals to the length of all vertical and...

Open the catalog to page 12

Pneumatic conveyor S 1000 in suction and force version consists of the following units - Fig. 4. 1 – fan 4 4 – suction cyclone 5 – compl. suction hose 6 – bend connector 7 – electrical installation tabliczka znamionowa Fig. 4. S 1000 in suction and force version. The drive of the fan of S 1000 contains electrical engine 7,5 kW. Rotational speed of the fan equals 2920 rev/min. At the side of air inlet, the fan is attached to the suction cyclone by means of bend connector, whereas outlet of the fan is connected by feeder pipe to the vane feeder and transportation pipeline. The suction cyclone...

Open the catalog to page 13

Pneumatic conveyor S 1000 in force version consists of the following units and parts – see Fig. 5.: 1 – fan 2 – framework/undercarriage 3 – feeder 4 – charging hopper 5 – horizontal throttling valve 6 – electrical installation tabliczka znamionowa Work in force system: The conveyor in force version works without flexible hose and nozzle, without suction cyclone and bend connector. At the side air inlet of the fan, there is a horizontal throttling valve assembled instead of the bend connector. Grain should be provided into charging hopper fixed on feeder instead of suction cyclone. The...

Open the catalog to page 14All Assentoft Silo catalogs and technical brochures

-

S1500 og 2000

49 Pages

-

T 207

49 Pages

-

Reactor tanks for biogas

12 Pages

-

Sealed storage

16 Pages