Catalog excerpts

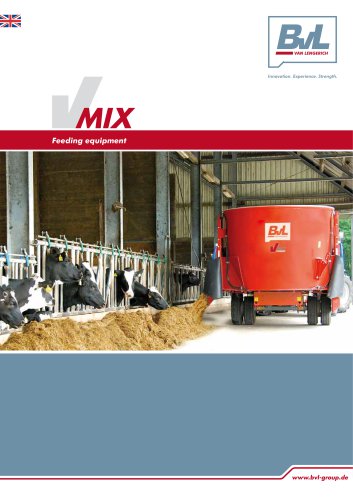

Innovation. Experience. Strength. Feeding equipment

Open the catalog to page 1

Bernard van Lengerich has been a household name for customized solutions since 1860. We will provide you with the products you need to optimize your profit and keep your animals as healthy as possible. After all, we do not act in the customer’s best interest if we sell him what we want to sell him. Instead, we need to sell him what he and his animals actually need. We work with an awareness of quality and value. Operating from the town of Emsbüren in the Emsland region, we manufacture exclusively in Germany and have turned Made in Germany into our most important seal of quality. We could...

Open the catalog to page 3

The patented eds system feeds precisely Faster and more consistent discharge – right where you want it The patented EDS system (Exact Dosing System) provides a fast and consistent discharge. Ensuring that the fodder comes out at the widest point on the side of the mixer wagon and is deposited in a loose swathe, the asymmetrical arrangement of the side doors prevents you from driving over the fodder. Consistent discharge – even without a conveyor belt The patented EDS system provides an extremely consistent fodder discharge – even without a conveyor belt. The doors are arranged so that they...

Open the catalog to page 4

The mixing hopper A structure-preserving and homogeneous mixing The mixing process We customize the mixing augers for every mixing hopper. This ensures that the mixing process in every vertical BvL mixer wagon is performed with utmost proficiency and energy efficiency. The result is a mixture that is homogeneous and characterized by a multitude of different structures. Optimized mixing process Benefits of asymmetrically positioned mixing wedges The asymmetrically arranged mixing wedges in the mixing hopper of mixer wagons that are equipped with two or three mixing augers provide for an...

Open the catalog to page 5

The power mixing auger Always the right type Our sturdy power mixing auger is the product of 30 years of experience. We use only the premium quality, highly wear-resistant “HARDOX 400“ special-purpose steel for the production of the leading edges. Always perfectly adapted to the contour of the hopper, the conical and slender shape of the auger guarantees high volume utilization as well as an extremely easy mixing process that is gentle on the fiber. The opening of entire round and square bales poses no problem at all. The power mixing auger can be optimally adapted to various fodder types...

Open the catalog to page 6

V-MIX Agilo Single-auger mixer 3.5 to 5 m³ – Five stars for the smallest model Offering capacities between 3.5 m³ and 5.0 m³, the V-MIX Agilo is small and exceptionally agile. “Nothing is impossible” is the motto of the smallest, yet fully capable mixer wagon, which fits in any building and can handle any amount of work for you. The discharge options The unique axle arrangement under the mixing hopper allows the V-MIX Agilo to be fitted for different discharge options. It can even be equipped with a cross conveyor at its rear. EDS discharge at the front right EDS discharge at the front...

Open the catalog to page 8

Independent loaders V-MIX Plus T Single-auger mixer 6.5 to 13 m³ – The lowest in its class The mixing hopper is positioned between the axle and the drawbar. The V-MIX Plus T is distinguished by an extremely low overall height (starting at 1.96 m) and is especially well suited for low door entries. This V-MIX Plus T also shows its advantages when used in combination with loading vehicles that have a low loading height. A low loading height saves time and makes the loading process easier. The discharge options The different arrangement options for the discharge openings allow you to customize...

Open the catalog to page 9

V-MIX Plus Single-auger mixer 6.5 to 15 m³ – The mixer wagon used by professionals The single-auger mixer wagon is available in sizes from 6.5 to 15 m³. Its “modular design” allows you to create a mixer wagon with perfect ease until you find the one that fits the needs of your agricultural enterprise best. The discharge options The V-MIX Plus shines with its plethora of discharge options. All available options can be tailored precisely to your requirements. We can implement discharge openings on the side, on the rear corners or at the center rear and even cross conveyors of different widths...

Open the catalog to page 10

Independent loaders V-MIX Plus Two-auger mixer 13 to 30 m³ – The compact two-auger mixers The two-auger mixers with 13, 15, 17 and 20 m³ are very compact and narrow mixer wagons. That way, large quantities can also be delivered in narrow feed passages. Offering exceptional volume utilization and the capacity to mix and transport large amounts of fodder, our larger two-auger mixers certainly rank among our other products that qualify as large-volume wonders. The discharge options Our two-auger mixers included in the V-MIX Plus series offer every farmer a host of different options when it...

Open the catalog to page 11

V-MIX Plus Triple-auger mixer 25 to 40 m³ – Mixing in large format … if you need to mix even larger quantities, BvL recommends the use of their triple auger equipment. Even with its 30 m³ capacity, these mixer wagons can negotiate feed passages with a clearance of only 2.85 m. The V-Mix Plus 3S offers the same advantages as its smaller siblings. The V-Mix Plus 3S is available in sizes from 25 to 40 m³. The discharge options Thanks to the large variety of discharge openings they offer, our triple auger mixers can be perfectly adjusted to the specific requirements existing on your farm. This...

Open the catalog to page 12

Independent loaders

Open the catalog to page 13

V-MIX Fill Everything in just one machine All benefits at a glance: • Smooth and clean silage clamp face • Silage storage density is maintained • Acceptance of fodder components without losses • Four work steps in one machine: The L and LS models of the V-MIX Fill series feature, respectively, a loading scoop for filling the mixer wagon and an integrated cutting unit. The proven BvL cutting unit cuts through any type of silage with perfect ease. Its active knife system allows the machine to cut silage slices of up to 40 cm out of the silage face, leaving behind a smooth and clean surface....

Open the catalog to page 15All Bernard van Lengerich Maschinenfabrik GmbH & Co. KG catalogs and technical brochures

-

FEED MIXER WAGON

24 Pages

-

FEEDING EQUIPMENT

28 Pages

-

V-BIO Biogas

14 Pages

-

V-MIX Agilo/Plus/Giant

185 Pages

-

Chemicals and filters

8 Pages

-

OceanRC/AF

14 Pages

-

V-SYSTEM

6 Pages

-

solids dispenser V-BIO

14 Pages

-

Bedding technology V-COMFORT

14 Pages

-

unloading technology V-LOAD

14 Pages

-

VSYSTEM

6 Pages

-

VMIXDRIVE

14 Pages

-

Vbio

14 Pages

-

Vcomfort

10 Pages

-

Vload

14 Pages

-

Vconnect

10 Pages