Website:

Big Dutchman

Website:

Big Dutchman

Catalog excerpts

Milling and mixing systems for the production of feed mixes

Open the catalog to page 1

Drum cleaners, hammer mills, filters, dry mixers, silos and The trend toward using home-grown cereals for the production of mixed feed is increasing. The farmer is able to produce individual feed mixes of known quality, saves transport costs and increases flexibility. Big Dutchman can offer you the necessary technology: ✔ rum cleaners to clean any type of crop d before milling; ✔ ammer mills with a high capacity; h ✔ ilters which reduce moisture and dust; f ✔ ifferent dry mixers (diagonal, horizontal); d ✔ ilos for indoor and outdoor use in s different sizes for grain storage, storage of...

Open the catalog to page 2

other machinery for on-farm feed production: custom-made s Hammer mills Uniform structure of the feed The Big Dutchman hammer mills operate with a driving power of 11 to 45 kW. Depending on the requirements, for example fine milling or feed with more structure, different mills and screens are used. The special milling control system ensures that the dosing auger correctly supplies the mill with the type of material that is to be milled. This means that the delivery rate is automatically adapted to the type of material conveyed. The type of mill installed (single, double or parallel mill)...

Open the catalog to page 3

solutions for small and large operations MicrosDry MicrosDry is the ideal solution for dosing of very small amounts. Every container is equipped with an agitator. This enables efficient handling even of slow-flowing raw materials. ✔ ontainers with 1 to 4 compartments c with a capacity of 25 L each; ✔ gitator in all containers; a ✔ easuring with an accuracy of 10 grams; m ✔ eighing container with a capacity of w 25 L; ✔ asy to clean and to service; e ✔ reat flexibility in terms of location. g High mixing accuracy, versatile use The diagonal and horizontal mixers offered by Big Dutchman can...

Open the catalog to page 4

Silos for indoor and outdoor use Storage of primary ingredients and finished feed mixes Big Dutchman can offer its customers a variety of silos made from different materials and in different sizes for safe storage of ingredients and finished feed mixes. The number and size of the silos are planned according to the individual Indoor silos for storage of completed mixes requirements on a farm. For slow-flowing materials there are special auger silos available. Outdoor silos for storage of ingredients Hoppers for minerals and premixes Ideal storage of small amounts Different types of hoppers...

Open the catalog to page 5

Control of milling plants with BigFarmNet Simple and effective process control More security Your entire production is recorded in one single software, which also means that all systems are backed up automatically and all alarms are managed centrally. Centralised data input and uniform user interfaces reduce the risk of incorrect inputs. Optimised production results and reduced costs Improve your production results by using efficient analytical tools, and save time and avoid errors thanks to optimised processes. At the office PC In the feed kitchen with our controllers Control your systems...

Open the catalog to page 6All Big Dutchman catalogs and technical brochures

-

Egg collection systems

8 Pages

-

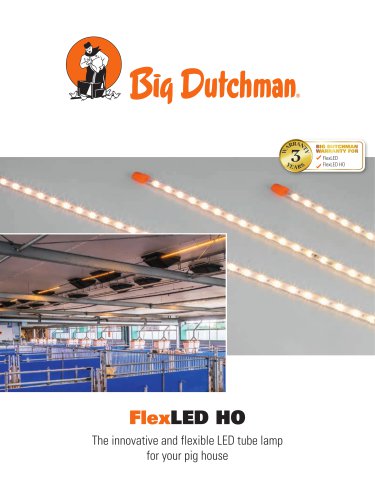

LED tube lamp FlexLED HO

2 Pages

-

Exhaust air chimneys

8 Pages

-

Vista 360 feed pan

2 Pages

-

NATURA Visio aviary system

2 Pages

-

Sharky 430 cleaning robot

2 Pages

-

Viva 330 feed pan

2 Pages

-

LED lighting

12 Pages

-

Fresh air supply systems - Pig

12 Pages

-

Fresh air supply systems

12 Pages

-

OneLite & DuoLite

2 Pages

-

Alarm systems

4 Pages

-

Earny 2 heat exchanger

6 Pages

-

AviMax transit broiler cage

8 Pages

-

SiloCheck Air

2 Pages

-

Wall fans AirMaster & Co.

12 Pages

-

UNIVENT-Starter 680-plus

2 Pages

-

Bird weighing

6 Pages

-

UniVent poultry cage

8 Pages

-

Sow management

16 Pages

-

Manure pit systems

4 Pages

-

Broiler breeder management

18 Pages

-

OptiScan

2 Pages

-

Heidy bird grader

2 Pages

-

CompoTower fermenter

4 Pages

-

FLUXX 330 & 360 feed pans

6 Pages

-

PURO air cleaning system

4 Pages

-

CombiTunnel ventilation

6 Pages

-

Imperator feed pan

2 Pages

-

Havito welfare barn

4 Pages

-

Housing equipment

4 Pages

-

Automatic feeders

4 Pages

-

Pekino cup drinker

2 Pages

-

LED retrofit kit

2 Pages

-

NATURA 70 aviary

6 Pages

-

EggSmart elevator

2 Pages

-

Cooling Systems

4 Pages

-

RainMaker pad cooling system

4 Pages

-

Breezy ventilation control

2 Pages

-

Porcus air srcubber

4 Pages

-

CompoLiner composting system

4 Pages

-

OptiSec Porco belt dryer

4 Pages

-

Moisture-proof LED lamp

2 Pages

-

Feed cart FC-V

4 Pages

-

MultiPan 395 feed pan

2 Pages

-

BD plastic slat

2 Pages

-

LED ceiling lamp Helios

2 Pages

-

Automatic chain feeding

4 Pages

-

NH3 Sensor DOL 53

2 Pages

-

Enrichment with PickPuck

2 Pages

-

AugerMatic feeding system

6 Pages

-

AviMax sliding broiler cage

2 Pages

-

Floor systems

4 Pages

Archived catalogs

-

Residue Treatment

12 Pages