Website:

Borghi Srl

Website:

Borghi Srl

Group: Borghi S.r.l.

Catalog excerpts

Operation manual AIRSEP

Open the catalog to page 1

Principle of working of AIRSEP

Open the catalog to page 2

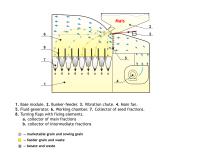

1. Base module. 2. Bunker-feeder. 3. Vibration chute. 4. Main fan. 5. Fluid generator. 6. Working chamber. 7. Collector of seed fractions. 8. Turning flaps with fixing elements. a. collector of main fractions b. collector of intermediate fractions O — marketable grain and sowing grain G — feeder grain and waste ■ — besatz and waste

Open the catalog to page 3

Loading, adjusting and turning the AIRSEP

Open the catalog to page 4

Connect the separator on to the electric network. . Load the grain into the bunker-feeder. Fix the turning flaps in this position.

Open the catalog to page 5

Direction of rotation of generator must correspond to an arrow after main fan switching on. You have to make changing of phase shift if you observe the wrong direction of rotation.

Open the catalog to page 8

Crack open the shutter providing minimal feeding of an initial material.

Open the catalog to page 10

This is the shutter of initial material feeding.

Open the catalog to page 11

In separated chamber fix an optimum pressure by means of power regulator of the air jet generator.

Open the catalog to page 12

The optimum air pressure in separated chamber is a feature of equal distribution of the initial material from the fifth and the second fractions.

Open the catalog to page 13

After regulation of pressure in separated chamber you can increase a content of the initial material through opening of shutter. You have to control the quality of grain in all fractions. Grain has to correspond to your demands.

Open the catalog to page 14

In the case of necessity increase an air pressure in separation chamber.

Open the catalog to page 15

Needed seeds are choosing from the separated mass by means of tuning flaps. So needed quality of grain is regulated at the output.

Open the catalog to page 16

The grain should not be in the deflection of light fractions under correct regulation of the air pressure.

Open the catalog to page 17

Switching on and ajustment have been done

Open the catalog to page 18

Close the shutter «Feed of corn for separation».

Open the catalog to page 20

Switching the vibrating chute off.

Open the catalog to page 21All Borghi Srl catalogs and technical brochures

-

Chain conveyors

4 Pages

-

Cooloer Freddy

1 Pages

-

Drum cleaner

2 Pages

-

FFB Filters

2 Pages

-

Flights conveyors

2 Pages

-

FTC Filters

6 Pages

-

Loading bins

2 Pages

-

Pneumatic conveyance

4 Pages

-

Pulitore AIR SEP

1 Pages

-

Revolving distributors

2 Pages

-

Revolving extracting screw

2 Pages

-

ROL fans

4 Pages

-

Rotary Cleaners

2 Pages

-

Sampling probe SP-SPR

4 Pages

-

Stainless steel piping

12 Pages

-

Tubular screws

2 Pages

-

Ventilation ducts

6 Pages

-

Horizontal silos

24 Pages

-

Burrowing unloader

4 Pages

-

BUCKET ELEVATOR

2 Pages

-

TN BELT CONVEYORS

2 Pages