Catalog excerpts

BusaDUR ® BusaDUR®– the uniqe Busatis wear protection technology The world’s first highly wear-resistant coating of the entire crop flow channel for self-propelled forage harvesters Advantages of BusaDUR ® wear protection coatings: highest service life cycles – depending on the coating thickness, a higher service life cycle of up to 600 % compared with uncoated parts can be obtained exceptionally smooth surface for efficient crop flow – friction and stick-effects are reduced – high throughput rate – less fuel consumption saving of cost and time – less downtime – less maintenance effort forming – ductile coating allows forming after sintering process the long-time field use throughout the world ensures that the technology is reliable and the wear protection coating compatible f

Open the catalog to page 1

BusaDUR ® – the uniqe Busatis wear protection technology Thanks to the continuous development of high-performance machinery used in different industrial fields, the long service life of wear parts is a requirement that has become considerably important over the years. Being able to offer solutions on customer request, Busatis continuously develops new technologies for highly wear-resistant coatings against abrasion, erosion, and impact stress. Challenge When developing new technologies, Busatis always focuses on enhancing the service life of wear parts, which are subject to increasing...

Open the catalog to page 2

Advantages BusaDUR® wear protection coatings achieve the following results: ► highest service life cycles - depending on the coating thickness, a higher service life cycle of up to 600 % compared with uncoated parts can be obtained ► exceptionally smooth surface for efficient crop flow - friction and stick-effects are reduced - high throughput rate - less fuel consumption ► saving of cost and time - less downtime - less maintenance effort ► no impact sensitivity ► forming of the coated parts according to the part geometry Possibilities for processing the coated parts: Laser cutting Water...

Open the catalog to page 3

Service life cycle of BusaDUR ® wear protection coating compared with uncoated materials steel quenched and tempered ~500 HV service life cycle The diagram shows the service life cycle increase using the Busatis BusaDUR® wear protection coating, compared with common known wear resistant steels. (ASTM G65 - carried out by AC2T Austrian Center of Competence for Tribology). Comparison in quality: BusaDUR ® wear protection coating Spiral bands in field use service life cycle without coating field use was stopped after 200 cutter head hours, spiral band is worn completely, 4 holes already...

Open the catalog to page 4All Busatis GmbH catalogs and technical brochures

-

Zone-hardened knife back

2 Pages

-

Straw chopper knives

2 Pages

-

Sickle sections

2 Pages

-

Forage harvester knives

4 Pages

-

Busa®CLAD

2 Pages

-

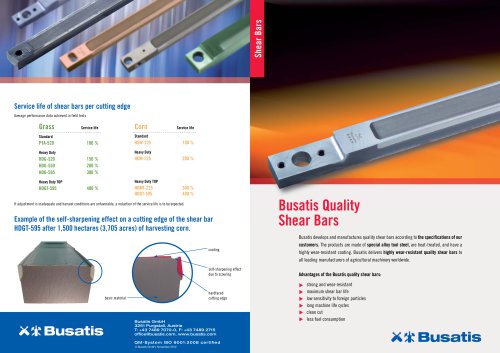

Shear Bars

2 Pages

-

HDG-550

2 Pages