Catalog excerpts

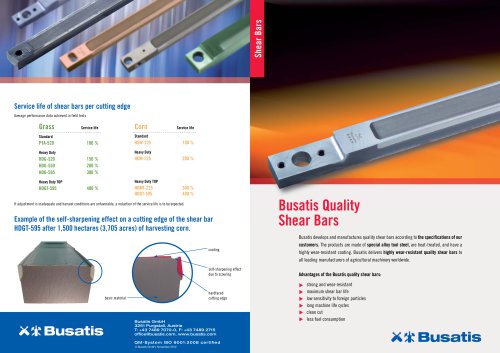

Shear Bars Service life of shear bars per cutting edge Average performance data achieved in field tests Service life Heavy Duty Heavy Duty Service life If adjustment is inadequate and harvest conditions are unfavorable, a reduction of the service life is to be expected. Example of the self-sharpening effect on a cutting edge of the shear bar HDGT-595 after 1,500 hectares (3,705 acres) of harvesting corn. coating self-sharpening effect due to scouring hardfaced cutting edge basic material Busatis GmbH 3251 Purgstall, Austria T: +43 7489 7070-0, F: +43 7489 2715 office@busatis.com, www.busatis.com QM-System ISO 9001:2008 certified © Busatis GmbH, November 2012 Busatis Quality Shear Bars Busatis develops and manufactures quality shear bars according to the specifications of our customers. The products are made of special alloy tool steel, are heat-treated, and have a highly wear-resistant coating. Busatis delivers highly wear-resistant quality shear bars to all leading manufacturers of agricultural machinery worldwide. Advantages of the Busatis quality shear bars: ▼ ▼ ▼ ▼ ▼ ▼ strong and wear-resistant maximum shear bar life low sensitivity to foreign particles long machine life cycles clean cut less fuel c

Open the catalog to page 1

Quality shear bars are manufactured according to your design and your needs PTA hardfacing for highest demands The plasma-powder welding takes place under the Plasma Transferred Arc (PTA) with temperatures over 10,000 °C (18,032 °F). Development. Continually, new cutting components are developed with the engineering and testing departments of the most important manufacturers of agricultural machinery in the world. The close cooperation with research departments of powder producers, universities in Europe and North America, and independent laboratories ensures a permanent exchange of...

Open the catalog to page 2All Busatis GmbH catalogs and technical brochures

-

Zone-hardened knife back

2 Pages

-

Straw chopper knives

2 Pages

-

Sickle sections

2 Pages

-

Forage harvester knives

4 Pages

-

Busa®CLAD

2 Pages

-

HDG-550

2 Pages

-

BusaDUR®

4 Pages