Website:

DICKEY-john

Website:

DICKEY-john

Group: TSI

Catalog excerpts

CONTROL SYSTEMS IntelliAg® puts the future of application control in your cab providing state-ofthe-art communication between implement and tractor.

Open the catalog to page 1

INTELLIAG CONTROL SYSTEMS ® Compatible with a variety of implements, the DICKEYjohn IntelliAg® Precision Farming System monitors and controls with just one terminal, eliminating the need for multiple controllers. Because IntelliAg is designed for the ISO 11783 standard, it is interchangeable with other manufacturers’ compatible equipment including: • John Deere • AGCO • Case IH Benefits of IntelliAg • SO 11783 conformance allows for a I common installation to interface with and operate multiple implements • tandard electrical connector at hitch for S convenient plug and play installation •...

Open the catalog to page 2

PLANTING Row Shutoff Module Row Shutoff Module is used to provide physical in-cab switching for manual on/off control of row section 1-6. The IntelliAg Planter/Drill System (PDC) provides planter monitoring and control of seeds being placed in soil by each row unit, including counting seeds planted per acre, inches between seeds and average population. Air Pressure Sensor measures air pressure in the seed hopper. Hopper Level Sensor Hopper Level Sensor alerts when seed or granular material reaches a low level in the hopper. Planter Base System • lanter monitor functionality (max. 196 rows)...

Open the catalog to page 3

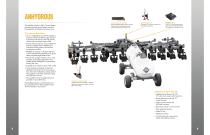

AIR SEEDING Hopper Level Sensor Hopper Level Sensor alerts when seed or granular material reaches a low level in the hopper. The IntelliAg Air Cart Control (ACC) System allows for full utilization of a 1 to 4 bin air cart. The system monitors seed or fertilizer traveling through the air system to ensure the material is getting to the soil and is not being trapped in a hose. Fan RPM Sensors measure the fan revolutions per minute. Air Pressure Sensor Air Pressure Sensor measures air pressure in the seed hopper. Implement Lift Switch Implement Lift Switch enables or disables implement function...

Open the catalog to page 4

ANHYDROUS Boom Shutoff Module Boom Shutoff Module is used to provide physical in-cab switching for manual on/off control of boom sections 1-6. The IntelliAg Anhydrous (NH3) Control System provides automatic ground speed control for the application of anhydrous ammonia only. Continental TTU allows for faster runs at lower tank pressures. WSMT2–NH3 processes sensor inputs and communicates them to the control unit in the tractor cab. The system provides: • p to 2 independent channels of anhydrous U ammonia control and allows large tool bars to be split in half and vary the rate of each section...

Open the catalog to page 5

AgGPS® 262 is used for position information in VRT mode. The IntelliAg Sprayer Control System (LIQIV) is designed with features tailored specifically for self‐propelled and pull-behind liquid sprayers. Boom Shutoff Module is used to provide physical in-cab switching for manual on/off control of boom sections 1-6. Liquid Control Valves control the flow of liquid based on messages sent from the tractor cab. IntelliAg Terminal WSMT2–LIQIV processes sensor inputs and communicates them to the control unit in the tractor cab. The Virtual Terminal is mounted inside the tractor cab and is the main...

Open the catalog to page 6

AgGPS 262 is used for position information in VRT mode. The IntelliAg Granular Spreader Control System (GCIV) is designed with features tailored specifically for self‐propelled and pull-behind granular spreaders. IntelliAg Terminal Boom Shutoff Module Hydraulic Control Valve Boom Shutoff Module is used to provide physical in-cab switching for manual on/off control of boom sections 1-6. The Virtual Terminal is mounted inside the tractor cab and is the main user interface with the IntelliAg system. Hydraulic Control Valve is used to regulate hydraulic oil flow to conveyor/auger motor and...

Open the catalog to page 7

SYSTEM DIAGRAM An As-Applied job can be started quickly to record as-applied data. Several features are available when creating an As-Applied job. Planter/Grain Drill Control Module 4 control channels can be set for planter seeding (seeds per acre), liquid spray (gallons per acre), or granular fertilizer (pounds per acre) application. Features include: • reating a field boundary C • reating exclusion zones C • reating flag points to mark field obstacles C • reating headlands C • sing boundary offsets U • xporting job as a .pdf to a job report E Implement CAN Breakaway Harness 46798013X...

Open the catalog to page 8

WORLD LEADER AGRICULTURE PRECISION When you take a need, add inspired ingenuity and develop the result with unsurpassed quality, you get market-leading technology in the Agriculture Industry Market-Leading Technology: • ICKEY-john developed the ag industry’s first D successful planter monitor • ICKEY-john was one of the industry’s first to be D ISO 9001: 2008 quality certified • ICKEY-john was the first to offer a complete D precision agriculture package with IntelliAg and Trimble AgGPS AutoSteering • ICKEY-john offers the award-winning handheld D moisture tester mini GAC® - that uses the...

Open the catalog to page 9

CONTROL SYSTEMS IntelliAg® puts the future of application control in your cab providing state-ofthe-art communication between implement and tractor.

Open the catalog to page 10

INTELLIAG CONTROL SYSTEMS ® Compatible with a variety of implements, the DICKEYjohn IntelliAg® Precision Farming System monitors and controls with just one terminal, eliminating the need for multiple controllers. Because IntelliAg is designed for the ISO 11783 standard, it is interchangeable with other manufacturers’ compatible equipment including: • John Deere • AGCO • Case IH Benefits of IntelliAg • SO 11783 conformance allows for a I common installation to interface with and operate multiple implements • tandard electrical connector at hitch for S convenient plug and play installation •...

Open the catalog to page 11

PLANTING Row Shutoff Module Row Shutoff Module is used to provide physical in-cab switching for manual on/off control of row section 1-6. The IntelliAg Planter/Drill System (PDC) provides planter monitoring and control of seeds being placed in soil by each row unit, including counting seeds planted per acre, inches between seeds and average population. Air Pressure Sensor measures air pressure in the seed hopper. Hopper Level Sensor Hopper Level Sensor alerts when seed or granular material reaches a low level in the hopper. The system provides: • lanter monitor functionality (max. 196 rows)...

Open the catalog to page 12All DICKEY-john catalogs and technical brochures

-

PUBLIC WORKS 2023 Parts Catalog

71 Pages

-

Agricultural Parts Catalog 2024

169 Pages

-

Hy Rate Plus LED Sensor

2 Pages

-

Daisy Chain Blockage

2 Pages

-

GAC 2700-UGMA Spec Sheet

2 Pages

-

GAC 2700-UGMA Brochure

5 Pages

-

GAC 2700-AGRI Spec Sheet

2 Pages

-

Moisture Testing Solutions

8 Pages

-

ASM™ II

2 Pages