Website:

ENIDINE

Website:

ENIDINE

Group: ITT Corporation

Catalog excerpts

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Air Springs for Industrial Applications

Open the catalog to page 1

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Air Spring Overview ITT air springs are air-tight and sturdy pneumatic actuators for demanding industrial applications. Air springs are highly durable, precisely engineered and cost-effective for use in a wide variety of actuation and vibration isolation applications. With time-tested designs, fabric-reinforced Neoprene or Natural Rubber flex member construction and corrosion-protected end retainers, air springs provide superior quality and performance. As an actuator, air springs provide linear or angular motion. These air springs offer...

Open the catalog to page 2

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Advantages of Air Springs Max. displacement 1.18 in. Displacement permissible between upper and lower end plate. Therefore, no costly machining of the mounting holes is required. Maximum tilt angle of 30° No costly reversing devices are necessary. Contact ITT or your local representative for technical help. 1.18 in. Maximum for triple convoluted Little space required, no sealing required Compared to conventional pneumatic cylinders, the minimum height of the ITT Air Spring is significantly lower at the same stroke. Stroke Stroke Minimum...

Open the catalog to page 3

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Installation and Operating Instructions Provide stroke limitations, to prevent exceeding the maximum allowable stroke height. Provide stops for minimal height, or use Air Springs with optional Internal Bumper. Correct Never use Air Springs in torsion. Installation Space Sufficient clearance should be allowed to avoid any chafing with the walls of the bellows.

Open the catalog to page 4

Natural Rubber (NR) Good all-round properties make natural rubber the ideal material for standard actuators. • Standard material for the model series C and R • High dynamic capability • Elasticity • Tensile strength • Resistance to tear propagation • Resistance to abrasive wear Air Actuators with Stainless-Steel Connecting Parts • Connecting plates made of 304 stainless steel and bead rings made of 316T and stainless steel. • High resistance to media such as acids, chemicals and cleaning agents • High wear-resistance and durability Chloroprene Rubber (CR) Chloroprene rubber boasts good...

Open the catalog to page 5

Selecting the correct air spring is simple using the provided guide below. Simply plug in the correct code abbreviations to determine the type and model from the following charts located within this catalog, this will be the part number you will use to order your specific model of air spring. Air Spring Part Number Ordering Example: YI - Imperial YM - Metric YR - Bellows Only F - Bellows air spring R - Rolling lobe air spring S - Sleeve-type rolling lobe air spring S - Single convolution bellows D - Double convolution bellows T - Triple convolution bellows Z - Cylindrical rolling lobe air...

Open the catalog to page 6

Specific Properties • Sleeve-type Rolling lobe type • Elastomer bellows permanently press-fitted to the connecting parts by metal crimp rings • Plastic connecting parts for smaller models • CR-elastomer • SZ air actuators require a minimum pressure • Version 4 including M30 x 1.5 nut • Version 2 and 3 with brass bolt Notes: *No internal bumper unless otherwise stated More esigns available on request. It is not recommended to exceed 80% of the maximum stroke.

Open the catalog to page 7

Specific Properties • Crimped bead plate connecting parts, permanently connected to the reinforced bead of the elastomer bellows via a forming process • Standard design uses NR elastomer • Also available in special types: ECO, CR, Niro and HP bumper unless otherwise stated **More designs available on request. It is not recommended to exceed 80% of the maximum stroke.

Open the catalog to page 8

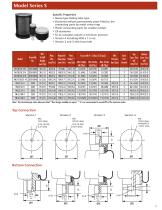

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Model C Series Specific Properties • Crimped bead plate connecting parts, permanently connected to the reinforced bead of the elastomer bellows via a forming process • Standard design uses NR elastomer • Also available in special types: ECO, CR, Niro and HP Triple Bellows Model Min. Max. Required Max. Install Dia. Height mm/[in] Clearance Stroke*** mm/[in] mm/[in] mm/[in] Force with P = 8 bar [120 psi]) Min Height kN/[lbs] Connecting Distance D Distance E Half Stroke Max Stroke Port mm/[in] mm/[in] kN/[lbs] kN/[lbs] Variant Notes: *No...

Open the catalog to page 9

Specific Properties • Bead ring connecting parts can be disassembled • Standard design uses NR elastomer • Also available in special types: ECO, CR, Niro and HP Notes: *More designs available on request. **It is not recommended to exceed 80% of the maximum stroke. (1) Does not apply to ECO or HP, (2) with p=6, (3) with p=7 bar.

Open the catalog to page 10

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Air Springs for Vibration Isolation In addition to actuation, many of our air springs can also be utilized as isolators with load bearing capacities ranging from 0.5 kN (112 lbs.) to over 350 kN (78 kip), A number of unique product features make air springs an ideal solution for many different and challenging vibration isolation applications. Product Features Constant Operating Height Our Air Springs are pressurized to maintain a set height, regardless of the load. There is no static spring deflection as with other spring elements. A...

Open the catalog to page 11

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Air Springs for Vibration Isolation - Model C Series 45kg Model Series C: Single Bellows 120 Required Pressure to Apply (PSI) Approximate Natural Frequency: 2.0 - 3.9 Hz 0 1000 lbs. Supported Weight in Application Per Air Spring Model Series C: Double Bellows 120 Required Pressure to Apply (PSI) Approximate Natural Frequency: 1.4 - 2.8 Hz Supported Weight in Application Per Air Spring

Open the catalog to page 12

AirSpring_Catalog_Enidine.qxp:Air Springs Conti 2015 Air Springs for Vibration Isolation - Model R Series Model Series R: Single Bellows 120 Approximate Natural Frequency: 1.9 - 2.2 Hz 0 1000 lbs. Supported Weight in Application Per Air Spring Model Series R: Double Bellows 120 Required Pressure to Apply (PSI) Required Pressure to Apply (PSI) Approximate Natural Frequency: 1.3 - 1.7 Hz Supported Weight in Application Per Air Spring

Open the catalog to page 13All ENIDINE catalogs and technical brochures

-

Visco-Elastic Support (VES)

4 Pages

-

Infrastructure Products

16 Pages

-

Global Presence

8 Pages

-

WR catalog

78 Pages

-

Wire Rope Technologies

4 Pages

-

Amortisseurs d'attelage

2 Pages

-

Brochure ressorts Jarret

2 Pages

-

Butoirs industriels ITT

8 Pages

-

Ressorts pneumatiques

44 Pages

-

Amortisseurs série HDN US

26 Pages

-

Technologies élastomères

4 Pages

-

Fixations de canalisations WEAR

22 Pages

-

Produits acier et grues

6 Pages

-

capacités ITT Enidine

8 Pages

-

amortisseurs industriels A4

180 Pages

-

Catalogue amortisseurs industriels

113 Pages