Catalog excerpts

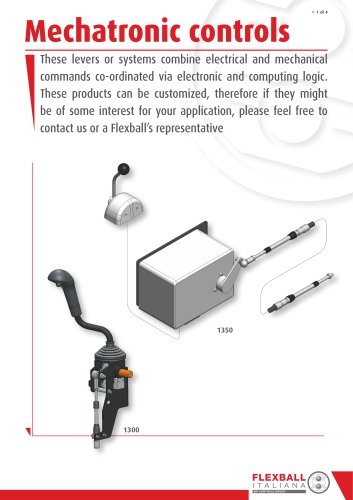

Mechatronic controls These levers or systems combine electrical and mechanical commands co-ordinated via electronic and computing logic. These products can be customized, therefore if they might be of some interest for your application, please feel free to contact us or a Flexball’s representative FLEXBALL I T A L I A N A WR CONTROLS GROUP

Open the catalog to page 1

LEVER 1300 This series of mechatronic controls is used to command the hydraulic pump for the motion of the machine. The lever combines a voltage output, generated from a Hall effect sensor, with a mechanical push-pull cable. A wide range of sticks with different bending and lengths fulfil most of the application requirements. On the handle can be mounted up to 3 push buttons, a rocker or a miniature electrical joystick. ratio: 11:1 • Lever angle: ±25 degrees • Mechanical stroke of the push-pull cable: 50 mm • Mechanical Voltage output signal • 0.50 V in forward position • 2.25 V in neutral...

Open the catalog to page 2

SYSTEM 1350 1350 is an automatic control system which provides significant fuel and wear reduction on excavators, backhoe and wheel loaders. SYSTEM SETUP It is basically composed of: Control lever 600 or on-off switches to define engine working speed Mechanical actuator to change the working speed as a consequence of the pressure needed in the hydraulic circuit Push-pull cable Cabling with electrical connection towards pressure transmitters Pressure transmitters Keypad for the setup programming Push-pull cable between actuator box and engine Actuator box that includes PCB and electric motor...

Open the catalog to page 3

AN ENERGY SAVER AND ENVIRONMENTAL FRIENDLY DEVICE The machine is usually set at its nominal speed, in order to generate the hydraulic power necessary to fulfil the most energy consuming operation. Most of the time however, the hydraulic circuit is generating more power than necessary and the excess of power is uselessly dissipated. If we consider how it works an excavator, the operator is selecting a fixed number of RPMs, which will not be changed for the whole working day, independently if the machine is standstill or digging. The power required in the two operating modes is different and...

Open the catalog to page 4All Flexball Italiana catalogs and technical brochures

-

460

2 Pages

-

415

2 Pages

-

410

2 Pages

-

400

2 Pages

-

ETC

8 Pages

-

1068

2 Pages

-

930

2 Pages

-

920

2 Pages

-

901

8 Pages

-

561

4 Pages

-

103

4 Pages

-

E95

8 Pages

-

2900

6 Pages

-

2800

4 Pages

-

2500

6 Pages

-

2000

2 Pages

-

1600

2 Pages

-

1500

6 Pages

-

1010

2 Pages

-

1200

2 Pages

-

630 Electronic control lever

2 Pages

-

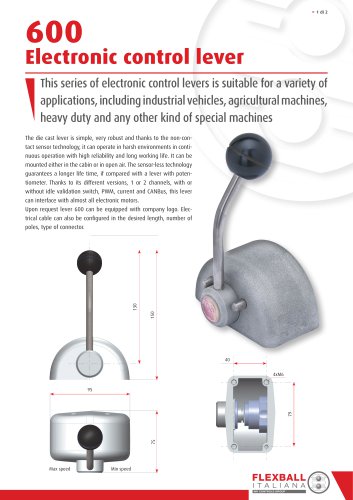

600 Electronic control lever

2 Pages

-

610 ELN control lever

2 Pages

-

1280

2 Pages

-

1270

2 Pages

-

1260 and 1262

2 Pages

-

1252

2 Pages

-

1240

4 Pages

-

700

12 Pages

-

1230

2 Pages

-

1220

2 Pages

-

1200

2 Pages

-

Industrial products

161 Pages