Website:

Grimme Landmaschinenfabrik GmbH & Co. KG

Website:

Grimme Landmaschinenfabrik GmbH & Co. KG

Group: Grimme

Catalog excerpts

POTATO TECHNOLOGY BEET TECHNOLOGY VEGETABLE TECHNOLOGY HARVESTING SUCCESS! 6-row beet harvester with 22- or 30-ton large bunker

Open the catalog to page 1

REXOR: The new dimension in beet harvesting! Matched to your requirements – are your specifications for the develop- variability in the defoliating system range, whether 22- or 30-ton large bunker – ment of state-of-the-art technologies. the REXOR is the tool of your choice. performance, reliability and profitability Combined with a high degree of Table of contents Defoliating systems Oppel wheel system and cleaning Bunker system Chassis 16–19 Engine and data management Product range beet technology Technical specificat

Open the catalog to page 2

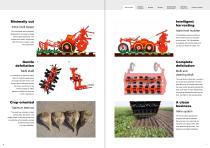

DIGGING / CLEANING Defoliating systems – chopping and scalping Grimme offers you three alter well-proven and used as a standard feature all over the world. In mulcher FM. Optimum defoliating leaf from the body of the beet. addition, you can choose between The inline topper with scalper is the inline multi topper with minimal ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Universal application scalper and the inline front natives for reliably removing the kinds of digging conditions. Inline topper Chopped material Even under the most adverse conditions, the topper and scalper...

Open the catalog to page 3

DIGGING / CLEANING developed for minimally cut beets special rotor shaft in conjunction this requirement. and cleans the beet crown such that the green leaf bases around the crown are removed. The minimal scalper (2) offers optimum conditions to carry out a thin crowning cut. Crop-oriented Optimum beet cut The result are minimally cut beet without green leaf bases. Low weight losses for the beet grower and no problems with processing caused by leaf remnants result in a high profitability. PRODUCT RANGE far the lowest losses in the beet's Chopped material with the minimal scalper meets...

Open the catalog to page 4

Oppel wheel digging Starting with the hydraulically driven Oppel wheel digging system via the beet handling system and ending at the REXOR cleaning system - the entire beet harvesting technology is designed for highest wear and an as gentle as possible DIGGING / „,,,.„,,-„ „,,„™,o ENGINE/DATA COMFORT/ „„■.,„,- DEFOLIATING CLEANING BUNKER CHASSIS MANAGEMENT OPERATION PRODUCT RANGE Oppel wheel The infinitely variable and drive Oppel wheels actively, yet very gently, lifts the beet out of the soil. Particularly under wet conditions, this minimises the intake of soil and guarantees digging...

Open the catalog to page 5

Loss-free digging Laterally moving Oppel wheels The hydraulically driven, laterally moving Oppel wheels (± 40 mm) permit an optimum intake DIGGING / CLEANING ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Effective and low-wear Cleaning unit From the roller table via the transport web and cleaning turbines up to the transfer elevator – the beet is effectively cleaned. Optimum transfer Share suspension Paddle shaft By default, the share brackets The paddle shaft gently transfers the are fixed on the frame with rubber beet to the roller table. Already there, bushes, which absorb...

Open the catalog to page 6

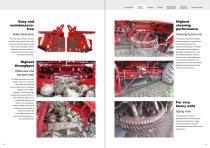

Easy and maintenancefree Roller table drive The roller table is driven by means of V-belts. One hydraulic motor each on the left-hand and right-hand side of the machine provides the drive. DIGGING / CLEANING ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Highest cleaning performance Cleaning turbine unit The second cleaning unit consists of three consecutive, amply dimensioned cleaning turbines with infinitely variable speed. The height Automatic reversion of rotation in of the guide bars is hydraulically case of jammed stones is part of adjustable. Cleaning turbine 1 can be...

Open the catalog to page 7

The bunker system Large-volume bunker capacities carries even largest amounts of with its transfer height of up to 4 m crop securely across the long and permits you to also use largely 1.80 m wide unloading web from dimensioned transport vehicles in you the freedom to dig even long non-stop digging operations. plots of land in one-man operation. wide clamp within a remarkably The Grimme unloading concept short time. The unloading web DIGGING / CLEANING ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Even filling Ring elevator and filler auger The third cleaning turbine transfers...

Open the catalog to page 8

DIGGING / CLEANING The chassis – protecting the soil and manoeuvrable ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Large volume wheels Despite the vehicle size, main compaction protection. The split with the four-wheel steering. In frame and chassis concept of the main frame is equipped with an addition, this chassis concept articulated joint with ± 35° bending makes it possible to select The front axle is equipped with unite a high degree of manoeuvr angle, thus making it possible for low-impact travel left and right, wheels size 800/70 R38 having ability, extremely high...

Open the catalog to page 9

Safe road drive Support wheel wagon For road drive, the support wheel wagon is coupled and uncoupled m auto atically from the cab by the driver. The load on the front axle is relieved, DIGGING / CLEANING ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Large steering angle Middle and rear axle The rear axle of the REXOR 620 has a maximum steering angle of ± 25°. The REXOR 630 has a maximum steering angle of ± 20° at the middle axle and ± 32° at the rear axle. the machine is prevented from swinging up. In the EU, the support wheel wagon is a legal requirement. Permissible axle...

Open the catalog to page 10

Fuel-saving engines and convenient data management DIGGING / CLEANING ENGINE / DATA MANAGEMENT COMFORT / OPERATION PRODUCT RANGE Modern drive line technology required for this are sometimes system, combined with the It is no longer only important to high. This is where the solutions engine's innovative control optimise one's own planning, but of Grimme i-systems come into The sophisticated hydraulic system, also to synchronise one's work the picture: They reduce the time with that of others. During the beet you spend on administration, rule most economical machine of its harvest this...

Open the catalog to page 11All Grimme Landmaschinenfabrik GmbH & Co. KG catalogs and technical brochures

-

EVO 290

9 Pages

-

EVO 280

9 Pages

-

SE 75/85-55

18 Pages

-

Windrower WR 200

6 Pages

-

Separating technology

11 Pages

-

SE 260

9 Pages

-

The MultiSep

3 Pages

-

Potato planter GL 32 F

3 Pages

-

PLANTING

19 Pages

-

CM1005B

2 Pages

-

CM

2 Pages

-

TRS-Serie

2 Pages

-

PO335BU

2 Pages

-

T-SerieIndustrie

2 Pages

-

PA-78

2 Pages

-

TRAILED HARVESTERS, T-SERIES

16 Pages

-

CARROT HARVESTER, T-10B

2 Pages

-

Product range

27 Pages

-

SE 150-60 bunker harvester

18 Pages

-

GT 170 elevator harvester

10 Pages

-

Trailed beet harvesting systems

17 Pages

-

MAXTRON 620 beet harvester

24 Pages

-

CR-1500

2 Pages

-

SV 260 bunker harvester

7 Pages

-

SE 75-20 bunker harvester

8 Pages

-

The GB-Series of Belt Planters

11 Pages

-

Potato

4 Pages

-

Machinery for active tillage

20 Pages