Catalog excerpts

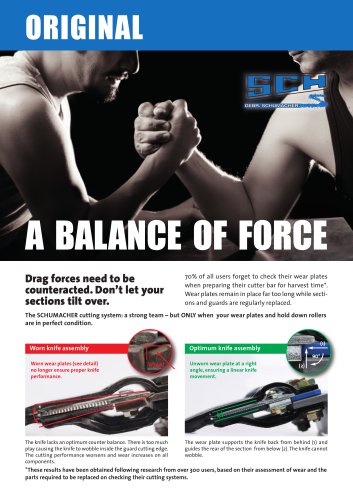

A BALANCE OF FORCE Drag forces need to be counteracted. Don’t let your sections tilt over. 70% of all users forget to check their wear plates when preparing their cutter bar for harvest time*. Wear plates remain in place far too long while sections and guards are regularly replaced. The SCHUMACHER cutting system: a strong team – but ONLY when your wear plates and hold down rollers are in perfect condition. Worn knife assembly Worn wear plates (see detail) no longer ensure proper knife performance. Unworn wear plate at a right angle, ensuring a linear knife movement. Optimum knife assembly The knife lacks an optimum counter balance. There is too much play causing the knife to wobble inside the guard cutting edge. The cutting performance worsens and wear increases on all components. The wear plate supports the knife back from behind (1) and guides the rear of the section from below (2). The knife cannot wobble. *These results have been obtained following research from over 300 users, based on their assessment of wear and the parts required to be replaced on checking their cutting system

Open the catalog to page 1

For optimum results SCHUMACHER recommends hold down rollers. Optimum knife assembly The box principle COUNTER FORCE Pressure disc Knife Section DRAG FORCE Ideal balance of forces under pressure Roller guide guard Knife back Wear plate The hold down roller guides the knife back. The hold down device ensures frictionless rotation during knife movement. Under pressure additional drag forces work on the section tip. The section tilts forward. This effect is counter-balanced by the hold down roller. Hence the knife maintains a linear movement inside the cutting gap even under pressure....

Open the catalog to page 2All Group Schumacher catalogs and technical brochures

-

ARISSTA

6 Pages

-

Hedge Trimmer

11 Pages

-

CROP LIFTER

13 Pages

-

Chopping TECHNOLOGY

7 Pages

-

SCHNITT punkt 2017-2018

12 Pages

-

Drive TECHNOLOGY

21 Pages

-

Cutting force

36 Pages