Catalog excerpts

Combine harvesting means high performance. Be equipped with the best for harvesting The cutting system as success factor 2

Open the catalog to page 2

■ Exceptional stability ■ Precise cut ■ Smooth run of cutting knife ■ Easy through flow ■ Easy handling as all parts are bolted ■ Universal modular system for use with all popular combine harvesters ■ Cuts all key crops such as cereals, canola, soybeans, rice, legumes and grass

Open the catalog to page 3

A precise and clean cut increases the overall performance of your harvest

Open the catalog to page 4

higher ground speed more harvesting hours smooth and secure driving SCH+

Open the catalog to page 5

Your harvest success starts with a clean cut Fill your grain tank 6

Open the catalog to page 6

EASY CUT Construction kit Guard 8 - 9 Hold down roller 16 - 17 Easy Cut Spare parts 20 - 23 Used wear plates 28 - 29

Open the catalog to page 7

The Schumacher guard with double counter edges for a balanced knife movement

Open the catalog to page 8

Box design Extreme height stability thanks to two-sided screw connection Perfect adaption and tight fit by mounting in combination with wear plates Double counter edges Strong non-wearing surface with elastic core Beveled cutting edges with special hardening process are extremely sharp and durable Precise cutting gap for smooth knife running 9

Open the catalog to page 9

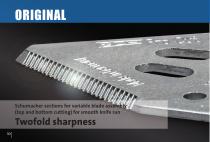

Schumacher sections for variable blade assembly (top and bottom cutting) for smooth knife run

Open the catalog to page 10

Cleaning edges Pro Cut sections are through hardened and zinc-coated Cleaning edges are particle-repellent and clean the cutting gap Optimized serrations for all harvesting conditions Tight fit Schumacher bolt with conical, serrated shaft for secure and firm positioning of the section in the knife back Easy to exchange thanks to screw connection

Open the catalog to page 11

Easy transport, storing and mounting

Open the catalog to page 12

Schumacher sectional knife Easy handling All knives fit in a 2.60 m box Easy to transport Quick and cost-effective shipping with overnight delivery service Knife connector kit Easy mounting Tight fit due to Precote-screws (The pre-coated adhesive is inactive and dry to the touch until the coated fastener is used. During assembly the adhesive is activated.) 13

Open the catalog to page 13

Drag forces need to be counteracted, don’t let your sections tilt over

Open the catalog to page 14

Schumacher wear plate The wear plate supports the knife back from behind (1) and guides the rear of the section from below (2). The knife cannot wobble Easy to exchange as single component

Open the catalog to page 15

The hold down roller guides the knife back by rotating frictionless Optimal knife guidance 16

Open the catalog to page 16

Hold down roller COUNTER FORCE Pressure disc Knife Section Roller guide DRAG FORCE Guard Knife back Wear plate The box principal Ball-bearing roller guides for particularly smooth running of the cutting knife Maintenance-free Keep the knife in the cutting gap straight even under heavy load 17

Open the catalog to page 17

Easy Cut kits have all parts and adaption components for my header type and length My Easy Cut cutting system 18

Open the catalog to page 18

Kits with all I need Easy Cut II kit ■ Guard + 1 spare guard ■ Sectional knife and all knife connection kits ■ Knife head and accessories ■ Knife guidance Standard: only wear plates Comfort: wear plates and hold down roller Premium: hold down roller and roller guide spacer plates ■ Crop lifter fixation ■ Bolts and nuts ■ Repair set sections ■ Mounting advice and spare parts list

Open the catalog to page 19

Original spare parts in Original boxes Maintaining cutting power 20

Open the catalog to page 20

Easy Cut spare parts Double guard Triple guard First guard Dimension -XPlease note: the mounting dimension determines the type of double guard (12/14/17 mm) and the thickness of the wear plate (4/5/6 mm) wear plate

Open the catalog to page 21

coarse 11 tpi = 11 teeth per inch i fine 14 tpi = 14 teeth per inch packaging unit 25 pieces ident-no. section bolt fine sections packaging unit 50 pieces

Open the catalog to page 22

Easy Cut spare parts Hold down roller Roller guide Wear plates grey khaki grey khaki dimension colour grey khaki

Open the catalog to page 23

This testing tool is the ideal companion for every combine harvester man

Open the catalog to page 24

Wear of guards Guards should be checked regularly for wear A cutting gap of more than 5.4 mm causes floating of the knife. The rounded cutting edges cannot cut the crops properly anymore. Stalks get pulled into the cutting gap

Open the catalog to page 25

Use a new section as a gauge and counter the worn section you want to check

Open the catalog to page 26

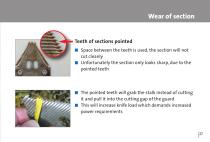

Teeth of sections pointed Space between the teeth is used, the section will not cut cleanly Unfortunately the section only looks sharp, due to the pointed teeth The pointed teeth will grab the stalk instead of cutting it and pull it into the cutting gap of the guard This will increase knife load which demands increased power requirements

Open the catalog to page 27

Worn wear plates no longer ensure proper knife performance Change wear plates 28

Open the catalog to page 28

Used wear plates Leveled wear plates The 90° angle of the wear plate is worn off The knife is not supported properly anymore and has too much play The cutting performance worsens and wear increases on all components The cutting performance worsens and wear increases on all components The knife lacks an optimum counter balance. There is too much play causing the knife to wobble inside the guard cutting edge

Open the catalog to page 29

Schumacher crop lifters lasts longer Tight and secure fit Excellent driving dynamics Height adjustment Quick fastener with locking strap Closed profile (slimProfile) to prevent reel tine intervention Optimal for challenging harvest conditions and down grain

Open the catalog to page 31

concave sliding skid The standard crop lifter, made by Schumacher first rivet with more clearance height mounting module with bend

Open the catalog to page 32

Strong shape The concave sliding skid provides a secure bottom guidance and high stability, even under difficult harvest conditions Strong drive The rolling sliding skid improves flexibility on the ground and driving dynamics The first rivet on the mounting module now has more ground clearance and therefore, lasts longer Strong profile The closed lifter profile prevents the reel tines getting caught when reversing

Open the catalog to page 33

original Drive dynamics Concave shaped profile Crop lifter remains solid Continuously concave sliding skid Therewith, the sliding skid has high stability, even under challenging harvest conditions and when cornering Critical wear appears only in the middle of the sliding skid, the sides remain solid Secure fit Ī Module with bend Wear of a mounting module operated parallel to the ground The new bend at the mounting module offers more ground clearance for the first rivet. So wear will be reduced consid

Open the catalog to page 34All Group Schumacher catalogs and technical brochures

-

ARISSTA

6 Pages

-

Hedge Trimmer

11 Pages

-

CROP LIFTER

13 Pages

-

Chopping TECHNOLOGY

7 Pages

-

SCHNITT punkt 2017-2018

12 Pages

-

Drive TECHNOLOGY

21 Pages

-

A balance of force

2 Pages