Catalog excerpts

Generation L The ASL grain lifter Harvest time - the clock is ticking! The Schumacher cutting system Cutting hedges properly KM hedge trimmers harvest SUCCESS Optimizing power flows High-efficiency drive technology Tying the knot Knotters for square balers Xchange Radura Parts ... and action for harvest pros Perfect Harvest.

Open the catalog to page 1

The 2017 harvest season left European farmers struggling with mixed weather and difficult conditions with lodged crops and wet fields. These are exactly the conditions where strong grain lifters come into their own. [in stormy weather!] Use grain lifters – boost your productivity ˾ Lifters significantly reduce losses in down crop ˾ Lifters reduce overall machine wear, because no soil will enter the combine when cutting too low Minimizing losses. Steffen Peil, western Germany • farms a 150ha family business • propagates spinach seed • 1 Fendt combine | 7.70m work width “I set very high...

Open the catalog to page 2

kinked SlimProfile Security label In 2018, Schumacher is going to introduce the new standard ASL grain lifter. The new model stands out for its different styling that sets it apart from the previous models. The new design falls into three aspects. The focus is on the actual skid. This was reinforced and given a wavy design which results in a substantially longer service life. The lifter profile, too, has changed. Its flattened end is kinked now to enhance the crop flow into the cutter bar. The type label has a holographic security sticker that identifies the lifter as a genuine SCH®...

Open the catalog to page 3

Higher workrates Wider harvest windows Quieter running More output The system is very robust. Really reliable, especially in wet conditions. My high expectations were more than met. Klein Bünzow Estate, north eastern Germany Bernhard Högner, Bavaria, Germany Eike Zschoche, eastern Germany • runs a 150ha family farm • runs a 400ha family farm • agricultural enterprise • conservation tillage • grass seed production • 2 New Holland axial flow combines • New Holland axial flow combine • Case IH axial flow combine • each machine combines 600ha “From the very first day, the Schumacher system...

Open the catalog to page 4

Harvest time - Rob Ewoldt, Rafter E. Ranch, Davenport, Iowa, USA Ron Thompson, Kasey Sander, Jeff Corlis, GROUP SCHUMACHER North America A difference like day and night. The Ewoldt family are corn and soybean growers in Iowa, USA. A board member of the Iowa Soybean Association since 2015, Rob listened very closely when friends were praising the Schumacher cutting system, reporting that the sections and the cutter bar offered a resistance to wear and a level of quiet running that was second to none. And so he decided to make the switch and fit the system to his 9.10m Flex header. The...

Open the catalog to page 5

Combining the Schumacher cutting system with a powerful EWM® drive is the optimum approach to trimming trees and shrubs professionally. ■ The unique cutting system applies clean cuts without splintering ■ A clean cut promotes a healthy regrowth ■ Trimming hedges, shrubs and trees EWM® hedge trimmers offer various work widths that suit individual needs and applications. They make perfect attachments for hydraulic booms, front-end loaders or excavator booms. ■ Light-weight design with C-Drive system ■ Great stability, cuts up to 20mm diameter branches ■ Suitable for wet conditions ■ 1.20m and...

Open the catalog to page 6

EWM® is the brand that powers cutter bars. The EWM® portfolio offers the perfect drive for every cutting system - on combines, windrowers and tool carriers. drive technology consistent and steady POWER flows with system in motion Innovative head bearings and knife heads make harvesters across the globe perform dependably. Prismatic attachment for Pro-Drive M EasyConnect attachment for Pro-Drive ECO available with POM ring, steel ring, or steel pot ■ For up to 7.50m cutting widths ■ For conditions involving little contamination ■ Innovative head bearing + Self-adjusting assembly + Fixed in...

Open the catalog to page 8

Thepower drivePro-Drive M planetary gearbox Absolutely straight knife stroke Suits a large number of different drive systems Suits mechanical and hydraulic drivelines EWM® planetary drives provide an absolutely straight stroke, which results in an equally straight power flow and knife stroke. Absolutely quiet running. Gerhard Hoben, GROUP SCHUMACHER Bernd Clasen, Matthiesen Ackerbau, north eastern Germany 1,500ha of land 2 Claas combine harvesters | 12m cutting dual-drive headers “There are many reasons why we are so happy with the technology and service of Schumacher. One is that the...

Open the catalog to page 9

The Rasspe® brand specializes in knotter systems for square balers. The Rasspe® portfolio comprises knotters for all baler capacities - from single knotters with two twines to HDC double knotters for high-capacity balers with up to 8 knotters. ■710 For small square balers Loop knotter ■ High knot strength For medium sized square balers ■ Basic type for simple applications ■ Undivided hub www.groupschumacher.com ■ High-performance ■ 2-3 knotter units ■ Divided hub ■ Easy maintenance ■ Available with centralized lubrication ■ HDC knotter ■ 4-6 knotter units ■ Divided hub ■ Collection of hay,...

Open the catalog to page 10

Rasspe® is the specialist manufacturer of knotters and binding systems complete with twine brakes and needles. Mongolia is a challenging region for small square balers. The Rasspe RS 6003 automatic lubrication system has been designed exactly for conditions like these. Auto lubrication reduces service & maintenance and extends the machine’s service life so it simply keeps going and tying dependable knots no matter what. The higher the bale density, the better Higher bale weights reduce transport costs. The RS 9000 ties stronger knots that are able to keep high-density bales in perfect...

Open the catalog to page 11

The biomass chopper The RS CutMaster is a simple and rugged machine that chops biomass for anaerobic digesters. Processes horse dung and manure for biogas production Shreds straw and hay for use as animal feed and bedding Effectively breaks up straw, hay and silage bales Watch the CutMaster in action on YouTube GROUP SCHUMACHER channel The mobile and universal chopper for manure and fibrous material Come to visit the Schumacher workbench Tips for exchanging parts properly. How to ... determine wear, ... find perfect-fit parts, ... replace them cleverly. • Straw chopper knives • Cutter...

Open the catalog to page 12All Group Schumacher catalogs and technical brochures

-

ARISSTA

6 Pages

-

Hedge Trimmer

11 Pages

-

CROP LIFTER

13 Pages

-

Chopping TECHNOLOGY

7 Pages

-

Drive TECHNOLOGY

21 Pages

-

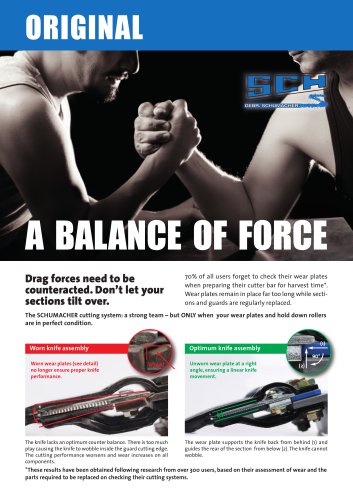

A balance of force

2 Pages

-

Cutting force

36 Pages