Catalog excerpts

Frame Dimensions In tubular steel structure Steering radius on the road [m] Steering radius at work [m] Gears Speed Steering system Parking brake Stationary brake Electric system Hydraulic system Dimensions of operational components Front track gauge [m]1,56 Rear track gauge [m]_1,56_ Fiat - Iveco motor with 6 cylinders N 67 MNT turbo intercooler 175 hp. A better reliability with more power and less pollutant emission Sauer-Danfoss high-pressure hydrostatic with 2 electro-hydraulically controlled mechanical ratios 1st work speed (slow) 2 work speed (fast) 3rt driving speed (slow) 4 driving speed (fast) Hurth hub with 8 stud bolts and 4 crown wheels Sauer-Danfoss hydrostatic hydraulic with oil bath disk on front and rear axle shafts with disk on the drive transmission no. independent lines Sauer-Danfoss hydraulic pumps_ Sauer-Danfoss hydraulic motors_ Buchler electro-distributors_ Sauer-Danfoss proportional distributors Brevini coupler_ Variable width of harvesting tips [cm] Header width [cm]_ Shaking chamber width [cm] cylinders diameter 20 [mm] stroke 25 [mm] (Bimba)_ Max. speed of sorter feeding belt 70 [m/min] Sorter fingers speed 35 [strokes/sec] CD +39 (0)532 883373 r.a. +39 (0)532 883254 Fax +39 (0)532 883191 www.guaresi.com e-mail: guaresi@guaresi.com a complete range of hi-tech

Open the catalog to page 1

The history of a trademark such as Guaresi cannot be made up out of thin air but has deep roots written in “Black and White”. It was indeed way back in 1932 that Cavalier Idalgo Guaresi began his artisan activity. Strongly influenced by the nearby presence of one of the first sugar-beet factories to be constructed in Italy, he began designing small sugar-beet farming equipment. The first man-driven machine to be patented and constructed placed three small doses of sugar-beet seeds and fertiliser in the ground. Right after the war other sugar-beet seeding and row-weeding machines were...

Open the catalog to page 2

L V ^7 L( a U J V cHnnn The tomato harvesters of the G-89/93 series are UU l_l UUUUUUUU v_Jv»>L_i LJ V^7 □ □ □ the evolution of the amazingly successful G89 model, which revolutionised tomato harvesting in the 90's. These machines are very much appreciated worldwide thanks to their outstanding production capacity and reliability, achieved thanks to constant development and to the use of top quality materials and components. The various operational components are very easily accessed thus making it extremely simple to clean and service the machine. The functional and comfortable...

Open the catalog to page 3

The tomato harvester model G 89/93 MS 32“, is the penetrating economic model of Guaresi's range of self-propelled machines. The slightly inclined belted chain, ensures a constant and evenly distributed flow of tomatoes in all harvesting conditions. It loads the electronic sorter feeding belt correctly and therefore each individual electronic sorter can perform its best. The particularly wide sorter footboard can take up to 6 workers to finish-off the tomato sorting phase. The highly efficient hydraulic system is made up of 7 independent lines, the speed of which can be adjusted from...

Open the catalog to page 4All GUARESI SpA catalogs and technical brochures

-

SUPER G 120-40"

2 Pages

-

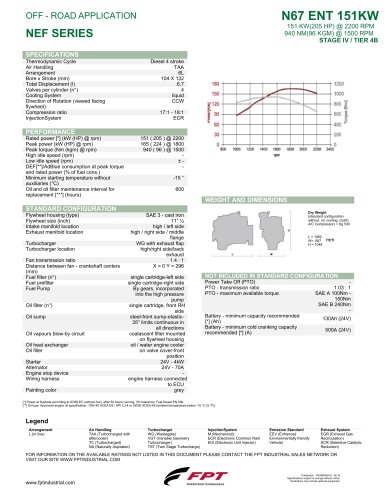

N67ENT

2 Pages

-

guaresi-super-g

2 Pages

-

N67 ENT 151KW

2 Pages