Catalog excerpts

Training Objectives Summarize CAN multiplexing history & origins Explain CAN technology Explain CAN benefits

Open the catalog to page 2

CAN stands for Controller Area Network Definition: Serial bus communication for real-time control application.

Open the catalog to page 3

What do we mean by CAN? CAN is a communication across a pair of wires to different nodes/microprocessors Messages on the CAN bus do not carry addresses, only identifiers Every node sees every message on the CAN bus CAN is a differential signal on two wires

Open the catalog to page 4

CAN (Controller Area Network) was created by Robert Bosch Gmbh in mid 1980’s Version 1.2 had 11 bit identifiers Version 2.0B released Sept. 1991 provided for 11 bit and 29 bit identifiers Base patent still held by Bosch

Open the catalog to page 5

1983 Developed by Bosch 1987 First CAN chips by Intel & Philips 1992 CAN is introduce to automation 1992 First car with CAN (Mercedes Benz) 1994 SAE J1939 released 1995 ISO 11898 is released

Open the catalog to page 6

Where is CAN used? General Applications – Cars – Packaging equipment – Medical systems – Photo copiers – Marine controls and navigation systems – Elevator controls HED examples – Military vehicles – Agriculture machinery – Construction equipment – On and off

Open the catalog to page 8

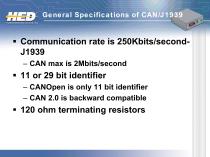

11 or 29 bit identifier – CANOpen is only 11 bit identifier – CAN 2.0 is backward compatible

Open the catalog to page 10

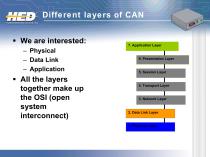

Different layers of CAN We are interested: – Physical – Data Link – Application All the layers together make up the OSI (open system interconnect) 2. Data Link Layer

Open the catalog to page 11

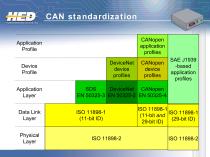

CAN standardization CANopen application profiles Application Profile Device Profile DeviceNet device profiles Application Layer SAE J1939 -based application profiles Data Link Layer Physical Layer CANopen device profiles

Open the catalog to page 12

Consist of the hardware needed to communicate from node to node – Physical/driver chip • Converts 1’s & 0’s to differential voltage – Twisted pair of wire – C

Open the catalog to page 13

The layer that defines data, remote, error, and overload frames. Layer that turns the data into raw bits Also part of the error detection

Open the catalog to page 16

Error Detection Bit Monitoring – Any node automatically monitors and compares the actual bit level on the bus with the level that it transmitted. If the two are not the same, a bit error is flagged. Stuff Error – If five consecutive identical bit levels have been transmitted, the transmitter will automatically inject (stuff) a bit of opposite polarity into the bit stream. The receive node will automatically de-stuff

Open the catalog to page 17

Error Detection Cyclic Redundancy Check Field (CRC) – Every message transmitted contains a 15 bit CRC code. If the receivers calculate a different CRC, a error flag is raised. Form Error – Violation of fixed format Bit fields Acknowledge Error (ACK) – If a node determines a message has not been ACKnowledged then the ACK error is flagg

Open the catalog to page 18

The application layer is the communication layer of the OSI. – Performs common end user services – HED application cod

Open the catalog to page 19

High Language Protocols J1939 – Diesel engines, busses, fire trucks, cranes, etc… CAN Kingdom CANOpen – Used in Europe especially Germany DeviceNet – Used in USA and Asia for PLC controllers

Open the catalog to page 20

HLP history HLP = Higher-layer protocol CAN Application Layer (CiA 20X series) Smart Distributed System (IEC 62026, EN 50325) CAN introduction - CAN protocols - CAN physical layer - CAN implementations - Higher-layer protocols - CAN applications

Open the catalog to page 21

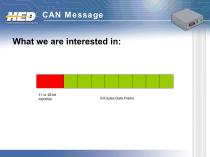

Full CAN message scheme: Data Length Code Cyclic Redundancy Check Data Frame Interframe Space

Open the catalog to page 22

0-8 bytes Data Frame

Open the catalog to page 23

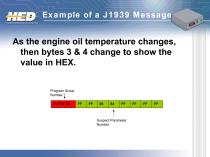

Program Group Number (pgn) 65262 – Engine Temperature 1 – ET1 Transmission rate: 1 sec Data Length: 8 bytes Data Page: 0 PDU Format: 254 PDU Specific: 238 Default Priority: 6 Parameter Group Number: 65262 (00FEEE hex) Bit Start Position 1 2 3-4 5-6 7 8 Bytes Length 1 byte 1 byte 2 bytes 2 bytes 1 byte 1 byte Suspect Parameter Number SPN Description Engine Coolant Temperature Fuel Temperature Engine Oil Temperature 1 Turbo Oil Temperature Engine Intercooler Temperature Engine Intercooler Thermostat Opening

Open the catalog to page 24

Example J1939 Message Suspect Parameter Number 175 – Engine Oil Temperature 1 Data Length: 2 bytes Resolution: 0.03125 deg C/bit, -273 deg C offset Data Range -273 to 1735 deg C Type: Measured Suspect Parameter Number: 175 Parameter Group Number: [65262] Program Group Number 00 FEE 00 Suspect Parameter Number

Open the catalog to page 25

As the engine oil temperature changes, then bytes 3 & 4 change to show the value in HEX. Program Group Number 00 FEE 00 Suspect Parameter Number

Open the catalog to page 26

SAE (Society of Automobile Engineers) CiA (CAN in Automation) ODVA (DeviceNet)

Open the catalog to page 27

Industry proven Bit collision detection and handling Cost saving Diagnostics for multiple module systems EMI/RFI

Open the catalog to page 28

Want to learn more? Check these websites for more information – www.sae.org – www.can-cia.org – www.hedonline.com HED papers – Large Scale Applications of J-193

Open the catalog to page 29

Training Objectives Summarize CAN multiplexing history & origins Explain CAN technology Explain CAN benefits

Open the catalog to page 30All HED Inc. catalogs and technical brochures

-

HED Application

12 Pages

-

Basic Electronics

32 Pages