Catalog excerpts

Tank breathing filters ▶ Size according to Hengst standard: 1 - 25 to 8-250 ▶ Connection G1 to DN250 ▶ Operating temperature ‒40 °C to +100 °C [‒40 °F to 212 °F] The breathing filters are used in hydraulic systems for breathing and bleeding air from the hydraulic tank. They are mounted directly on the tank. Features 1 Ordering code filter 2, 3 Preferred types 4 Symbol 4 Function, section 5 Technical data 6 Compatibility with permitted hydraulic fluids 6 Characteristic curves 7 Dimensions 8 ... 11 Ordering code spare parts 12 Assembly, commissioning, maintenance 13 Tightening torques 14 Directives and standardization 14 They distinguish themselves by the following: ▶ Highly efficient, special filter material ▶ Filtration of ultra-fine particles and high dirt holding capacity ▶ Use of Aquasorb filter material minimizes the risk of corrosion in the hydraulic tank ▶ Standard filling strainer in version TLF III ▶ Replaceable filter element

Open the catalog to page 1

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters Ordering code filter Size 1-25 to 6-80 01 Tank breathing filters Connection Internal thread Male thread Male thread and filling strainer Glass fiber material, not cleanable Air retention, ASHRAE 52.1, test dust SAE fine: 95% for particles > 0.3 μm Nominal Filter paper, not cleanable Air retention, ASHRAE 52.1, test dust SAE fine: 95% for particles > 1.24 μm Max. admissible pressure differential of the filter element of 1 bar [14.5 psi] Without solenoid Without valve Without maintenance indicator Connection...

Open the catalog to page 2

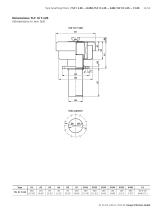

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 3/14 Ordering code filter Size 7-125 to 8-250 01 Tank breathing filters DIN-flange and filling strainer Size TLF I; TLF III Glass fiber material, not cleanable Air retention, ASHRAE 52.1, test dust SAE fine: 95% for particles > 0.3 μm Nominal Filter paper, not cleanable Air retention, ASHRAE 52.1, test dust SAE fine: 95% for particles > 1.24 μm Max. admissible pressure differential of the filter element of 1 bar [14.5 psi] Without solenoid Without valve Without maintenance indicator Connection Frame size...

Open the catalog to page 3

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters Preferred types Tank breathing filters TLF I, filter rating paper 10 μm Type Material no. Replacement element Material no. Replacement element Material no. Replacement element Tank breathing filters TLF II, filter rating paper 10 μm Tank breathing filters TLF III, filter rating paper 10 μm Symbol Tank breathing filters A Hengst Filtration GmbH, RE 51415, edition: 2

Open the catalog to page 4

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 5/14 Function, section The tank breathing filter guarantees air exchange in the fluid tank. Depending on the machine cycles, air can be pulled into the tank with contamination when a breather filter is not used. A tank breather filter will accomplish both the pressure equalization and air filtration preventing contamination from entering the tank through the air exchange. It basically consists of a threaded cover (1), a filter element (2) and a bottom housing (3) to accommodate the filter element. The...

Open the catalog to page 5

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters Technical data (For applications outside these parameters, please consult us!) General Installation position Tank structure Operating temperature Ambient temperature range Storage conditions °C [°F] ‒20 … +65 [‒4 … +149]; max. relative air humidity of 65% Size Polyamide (sizes 1-25 and 2-32), tin-coated steel (NG 3-40 to 8-250) ▶ Lower filter part Tin-coated steel (version I), aluminum / tin-coated steel (versions II and III) Stainless steel / aluminum Compatibility with permitted hydraulic fluids TLF II,...

Open the catalog to page 6

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 7/14 Characteristic curves (measured at test temperature = 20 °C [68 °F]) TLF…1-25, TLF…2-32

Open the catalog to page 7

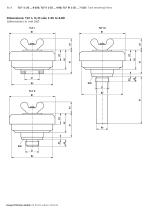

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters Dimensions: TLF I; II; III size 1-25 to 6-80 (dimensions in mm [in]) TLF III Hengst Filtration GmbH, RE 51415, edition: 2021-04

Open the catalog to page 8

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 9/14 Dimensions: TLF I; II; III size 1-25 to 6-80 (dimensions in mm [in]) Type

Open the catalog to page 9

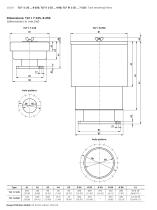

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters hole pattern Hengst Filtration GmbH, RE 51415, ed

Open the catalog to page 10

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 11/14 hole pattern RE 51415, edition: 2021-04, Hengst Filt

Open the catalog to page 11

TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 | Tank breathing filters Ordering code spare parts Filter element 01 Air retention, ASHRAE 52.1, test dust SAE fine Glass fiber material, not cleanable Filter paper, not cleanable Max. admissible pressure differential of the filter element of 1 bar [14.5 psi] Bypass valve Without bypass valve Order example: 7.002 P10-S00-0-M Material no.: R928039681 For detailed information on Hengst filter elements please refer to data sheet 51420. Preferred program replacement elements Filter element type Hengst Filtration GmbH, RE 51415, edit

Open the catalog to page 12

Tank breathing filters | TLF I 1-25 … 8-250; TLF II 1-25 … 6-80; TLF III 1-25 … 7-125 13/14 Assembly, commissioning, maintenance Assembly ▶ The filter connection must correspond to the tank connection. ▶ If the size is TLF ... 7 or the TLF I 8 version is used (version with DIN flanges), the hole pattern (DIN 2573) of the tank must be compared to the dimensions from the “Dimensions” chapter prior to installation. ▶ Install the filter on the tank. ▶ When installing the filter, the required servicing height of the replacement filter must be taken into account. ▶ For servicing reasons, we...

Open the catalog to page 13