Catalog excerpts

HULTDIN SYSTEM AB – ONE OF THE WORLD’S LEADING MANUFACTURERS OF FORESTRY ATTACHMENTS. HEADQUARTERS AND MAIN PART OF THE PRODUCTION IS LOCATED IN SCENIC MALÅ, NORTHERN SWEDEN. Hultdins SuperGrip is the best selling professional timber grapple in the world. No matter if it is on a forwarder, self loader or excavator, in desert heat or freezing cold, on a sunny day or in pouring rain. Every hour of the day, every day of the year, tens of thousands of Hultdins grapples are handling various logs in all corners of the globe. This is not a mere coincidence. Hultdins has developed and produced...

Open the catalog to page 3

SUPERGRIP II Features • Optimized design that secures high quality and strength • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • High strength steel and robotized welding ensures minimized down time • Grapple saw option available on all models Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min

Open the catalog to page 4

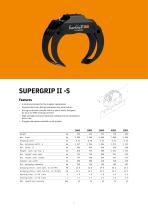

SUPERGRIP II -S Features • A reinforced model for the tougher applications • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • High strength steel and robotized welding ensures minimized down time • Grapple saw option available on all models Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min

Open the catalog to page 5

SUPERGRIP II-R Features • For handling of slash and bioenergy wood (Note! Not suitable for stumps) • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • High strength steel and robotized welding ensures minimized down time • The R-model is based on the arms of the respective S-model Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min Max....

Open the catalog to page 6

SUPERGRIP II -A Features • Unique arm geometry improves the selection and handling of individual logs • Asymmetric grapple arm design improves the “rolling” of the logs into the grapple during the loading process • The pointy grapple tip design minimizes the picking of unwanted debris • The A-grapple works well in multiple applications from the handling of round wood to bio-mass applications Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time,...

Open the catalog to page 7

“We are driven by constantly creating products that streamline the forestry of today and tomorrow.” BY HULTDINS

Open the catalog to page 8

SUPERGRIP Features • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • High strength steel and robotized welding ensures minimized down time • Grapple saw option available on all models Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min

Open the catalog to page 10

SUPERGRIP -S Features • Heavily reinforced model for the toughest jobs in the forest and excavator applications • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • Strong casted push rods • Grapple saw option available on all models Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min

Open the catalog to page 11

SUPERGRIP -RS Features • Extra heavily reinforced model for the toughest jobs in the forest and excavator applications • Tapered sleeve pin design eliminates any joint motion • Strong casted push rod • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • Grapple saw option available on all models Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min Max. operating p

Open the catalog to page 12

SUPERGRIP -R Features • For handling of slash and bioenergy wood • Tapered sleeve pin design eliminates any joint motion • Strong cushioned cylinder reduces shock loads, designed for up to 25 MPa working pressure • High strength steel and robotized welding ensures minimized down time Gripping area Height, arms tip–tip, C Max. height arms open Min. height arms closed Gripping force, arms open, at 25 MPa Gripping force, arms tip–tip, at 25 MPa Opening time, at 50 l/min Closing time, at 50 l/min

Open the catalog to page 13

YOUR PRODUCTIVITY - OUR DRIVING FORCE Hultdin System AB is a world leading manufacturer of components to mechanized forestry. With the productivity and profitability of our customers in focus we have over the years developed a wide product range consisting of Grapples, Saw Units, Grapple Saws, Damping Systems, and Active Load Space for forwarders and a Terrain Bridge for forestry machines.

Open the catalog to page 14

Hultdins’ log grapples are divided into three series, each with slightly different characteristics. However, common to all is that they’re designed to increase your productivity and every component is of high quality. Today, our grapples are fitted as standard by many major forwarder manufacturers. Today, every other tree in the world is harvested with a Hultdins SuperCut – and that says a lot about the knowledge we’ve accumulated over the years. Our goal is to make your work as painless as possible. We try to achieve this with innovative solutions, such as automatic chain tensioning, fully...

Open the catalog to page 15All ICAR BAZZOLI ENZO s.r.l. catalogs and technical brochures

-

TRACTORS FORESTAL LOADERS

9 Pages

-

IB 1600

2 Pages

-

Grapples and Rotators

2 Pages

-

Forestal Loaders

28 Pages