Catalog excerpts

WHY I-FEEDER DOSING SYSTEMS

Open the catalog to page 1

growth through service and innovation

Open the catalog to page 2

There are 3 main types of liquid chemical dosing: o Centrifugal pumps with flowmeter and fluid control valve o Positive displacement pump with piston liquid-end drive o Positive displacement pump with diaphragm liquids drive

Open the catalog to page 3

PRINCIPLES OF DIFFERENT DOSING METHODS o Centrifugal pumps with flowmeter and fluid control valve: dosing is administered by using a centrifugal pump in conjunction with a flowmeter. The centrifugal unit pumps the fluid from the tank into the mainline. The flow meter is used as control unit together with a tap to dose the desired volume. Positive displacement pump with piston liquid-end drive: The electric motor drives an eccentric cam which in turn drives the piston. The piston forms a vacuum inside the liquid-end head which is how fluid is suctioned from the tank and dosed into the...

Open the catalog to page 4

Advantages: o Low capital cost o High flow volumes Disadvantages: o High long term maintenance and part replacement cost o High labor cost as unit needs to be supervised to ensure continuous correct flow o Unreliable as dosing subject to pressure and flow variations in main line o Erosion high on seals, flowmeters, impellors, seals and other liquid-end items o Long list of working parts which need maintenance

Open the catalog to page 5

POSITIVE DISPLACEMENT PUMPS WITH PISTON LIQUID-END DRIVE Advantages: o Highly Accurate High pressure capabilities Sensitive to air – cannot run without liquid-end being wetted Sensitive to granules and impurities as piston and seals can scratch which breaks the vacuum Labor intensive when problems arise in the liquid-end Most expensive option

Open the catalog to page 6

OPTION 3: POSITIVE DISPLACEMENT PUMPS WITH DIAPHRAGM LIQUID-END DRIVE Advantages: o Accurate, durable and economical o Unaffected by outside influences such as pressure and water flow variations o Easy to maintain with most maintenance capable to be carried out on site o Easy to use with little wearable parts, especially liquid-end o Can run dry and not sensitive to impurities and granules Disadvantages: o Sensitive to blocked situations such as closed taps or blocked filters o Not measurable by off-the-shelf flowmeters

Open the catalog to page 7

1: History o Company founded in 1981 o Main shareholder control in hands of founding family ensuring a high level of quality control o Main business unit has at its core dosinq systems Growth through service and innovation o Company ethos is growth through service and innovation Footprints through all of Africa, Middle east, Europe and Asia

Open the catalog to page 9

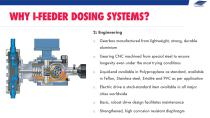

2: Engineering o Gearbox manufactured from lightweight, strong, durable aluminium o Gearing CNC machined from special steel to ensure longevity even under the most trying conditions o Liquid-end available in Polypropylene as standard, available in Teflon, Stainless steel, Ertalite and PVC as per application o Electric drive a stock-standard item available in all major cities worldwide o Basic, robust drive design facilitates maintenance o Strengthened, high corrosion resistant diaphragm

Open the catalog to page 10

3: Functionality: o Can run up to 4 gearboxes dosing either a high volume or 4 different volumes in proportional volumes o 1 gearbox size capable of dosing from a maximum of 50 Iph to 1200 Iph o 2 liquid-end volume sizes for all capabilities o Low stock keeping due to design form and function o Lightweight keeping freight costs low o Accurately adjustable between 20 and 100 % Pumps can be upgraded without needing to purchase a new pump at considerably lower cost.

Open the catalog to page 11

4: Service: o Due to design easily serviceable on site o Minimum working parts which needs maintenance o Product sold through agents on site in area, not directly from manufacturer o Part-list small thus stock-keeping minimal o Sold as turnkey thus no additional sourcing required, and also ensures correct installation o Installation simple

Open the catalog to page 12

5: Exports: o Proven design with footprint in all of Africa, Europe, Asia and the Middle East o Light-weight for low freight cost o Turn-key supply for instant installation, ease of use o Accuracy with simple operation o Basic training from installation manual sufficient, ensuring the sales agents need not be on site to install.

Open the catalog to page 13

WORKING HAND-IN-HAND WITH OUR AGENTS

Open the catalog to page 14

Determinants: o Volume of product to be dosed o Maximum operating pressure o Product to be dosed o Power supply o Manual of automated control If automated, what are results required

Open the catalog to page 15

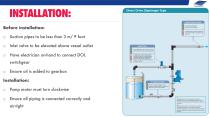

INSTALLATION: Before installation: o Suction pipes to be less than 3 m/9 foot o Inlet valve to be elevated above vessel outlet o Have electrician on-hand to connect DOL switchgear o Ensure oil is added to gearbox Installation: o Pump motor must turn clockwise o Ensure all piping is connected correctly and air-tight Direct Drive Diaphragm Type I To prevent overfeeding ^ siphoning-2 and dripping ‘ Install the back pressure valve n< the injection point on the discharge piping.

Open the catalog to page 16

De-aeration: o Attach suction pipe and run pump into open-ended line Calibration: o Always to be calibrated while dosing system under pressure o Use a calibrated column o Calibration only necessary with initial set-up Direct Drive Diaphragm Type

Open the catalog to page 17

We have automated dosing systems, capable of: o Proportional dosing o pH/ EC control o Volume dosed setting o Cloud reporting o Time control o Block controlled dosing

Open the catalog to page 18

Why automate? o Produce better crop yields. o Lower your operating costs. o Manage your systems remotely o Automate up-to-date information as required for reporting purposes o Fertigation control o Easier compliance and implementation of export conditions and regulations

Open the catalog to page 19

IN-FIELD INSTALLATIONS:

Open the catalog to page 21

IN-FIELD INSTALLATIONS:

Open the catalog to page 22All Irriquip CC catalogs and technical brochures

-

TYPICAL BASIC INSTALLATION

1 Pages

-

MIXER INSTALLATION MANUAL

2 Pages

-

MXD DOSING PUMP MANUAL 2020

16 Pages