Website:

Josef Romberger Maschinenfabrik GmbH

Website:

Josef Romberger Maschinenfabrik GmbH

Catalog excerpts

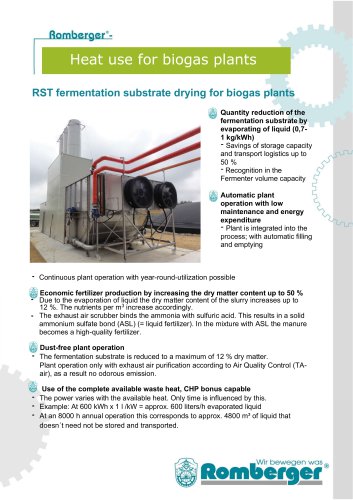

Heat use for biogas plants RST fermentation substrate drying for biogas plants Quantity reduction of the fermentation substrate by evaporating of liquid (0,71 kg/kWh) - Savings of storage capacity and transport logistics up to 50 % - Recognition in the Fermenter volume capacity Automatic plant operation with low maintenance and energy expenditure - Plant is integrated into the process; with automatic filling and emptying - Continuous plant operation with year-round-utilization possible Economic fertilizer production by increasing the dry matter content up to 50 % - Due to the evaporation of liquid the dry matter content of the slurry increases up to 12 %. The nutrients per m3 increase accordingly. - The exhaust air scrubber binds the ammonia with sulfuric acid. This results in a solid ammonium sulfate bond (ASL) (= liquid fertilizer). In the mixture with ASL the manure becomes a high-quality fertilizer. Dust-free plant operation - The fermentation substrate is reduced to a maximum of 12 % dry matter. Plant operation only with exhaust air purification according to Air Quality Control (TAair), as a result no odorous emission. Use of the complete available waste heat, CHP bonus capable - The power varies with the available heat. Only time is influenced by this. - Example: At 600 kWh x 1 l /kW = approx. 600 liters/h evaporated liquid - At an 8000 h annual operation this corresponds to approx. 4800 m³ of liquid that doesn´t need not be stored and transported.

Open the catalog to page 1

Function: It is a plant for increasing the solid content in the fermentation substrate by evaporation of liquid. Rotating drums immerse continuously heated contact plates in the substrate. The moistened metal sheets are guided into the air flow. The heated air flows through the sheets and takes away the evaporated liquid. This results in high-quality manure as the nutrient content is doubled by the reduction of the amount. In addition, the volume reduction saves logistics efforts and costs when bringing out the manure. In order to grant the CHP bonus, the following points have to be proven:...

Open the catalog to page 2All Josef Romberger Maschinenfabrik GmbH catalogs and technical brochures

-

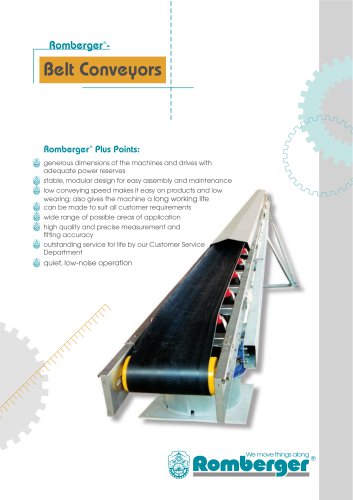

Belt Conveyors

4 Pages

-

Bucket Elevators

4 Pages

-

Chain conveyors

2 Pages

-

Screw Conveyors

4 Pages