Catalog excerpts

@ KQMPTECH CRAMBO E-MOBILE Shredder for wood and green waste

Open the catalog to page 1

Low-speed dual-shaft shredder for wood and green waste The Crambo is one of the best machines there is for shredding all types of wood and green waste. The e-mobile series adds semi-mobile electric-powered versions to the line-up, featuring maintenance-free electric motors instead of diesel engines. The concept combines the compact design and flexibility of a mobile machine with the energy efficiency of a stationary machine. Two slow-running drums with shredding teeth minimize fine particle and noise/dust emissions, and resist contraries. The Crambo enables easy adjustment of the output...

Open the catalog to page 2

Wide range of applications 03 Green waste, woody biomass A high throughput of bulky vegetation is made possible by the generously dimensioned feed area, folding hopper and counter-rotating teeth. Blockages from wet material and high grass content are practically impossible. The teeth clear the screen baskets on every revolution. Rootstocks, forest wood residue If a rootstock fits into the shredding area, it will also go through. The highly effective tooth power offered by the efficient drive, the intense motion of the material and the insensitivity to embedded stones all make the Crambo...

Open the catalog to page 3

The machine in greater detail Every Komptech machine meets the highest requirements for dependability and value retention. This is assured by the use of high-quality components, certified production and gapless quality control. Electric motor • Three-phase asynchronous motor with high efficiency (up to 95 %) • No exhaust emissions at the operating site, 100% CO2 reduction with green electricity • Fully encapsulated engine compartment to reduce noise emissions Drum drive • Hydraulic drive with load-dependent speed regulation • Optimum protection of all components through solid engine...

Open the catalog to page 4

Options Shredding drums Specially developed bearings keep the massive shredding drums securely in place, even under extreme loads. Strong planetary gears boost drive train life, for dependable service through thousands of operating hours. Teeth With their carefully designed profile, the drop-forged wear teeth ensure maximum service life and consistent functionality. The all-purpose sickle teeth deliver aggressive feed and good cutting. The planing teeth give good results on waste wood when used with smaller screen baskets. Their shape makes them very long-lived. Bio cutting unit This...

Open the catalog to page 5

Over seven cubic metres hopper volume Just load material into the big hopper – the machine does the rest. Hydraulically folding hopper sidewalls make the already generous shredding chamber even bigger. Steplessly adjustable drum speed (hydraulic) Reversing programs Swivel screen basket Efficient shredding The use of an electric motor instead of a diesel engine offers significant advantages in energy efficiency. Electric motors can have efficiencies up to 95 percent, while diesel engines max out at 30 to 35 percent. With comparable throughput, up to 70 percent of the energy costs can be...

Open the catalog to page 6

The Komptech plus Top advice We'll show you how to optimize your processes, based on our experience and extensive data analyses. Service near you Expert technicians are on-site quickly to make sure your machines keep running. All-in solutions From individual mobile machines to complex stationary systems, with us you get the right process solution. At Productivity in view Apps and integrated monitoring let you keep an eye on operating data and economy. Spare parts always available Intelligent stocking for the fast, economical provision of high-quality spare parts. Need-based service Our...

Open the catalog to page 7

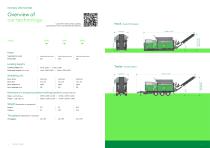

TECHNICAL SPECIFICATIONS Look here for the newest updates, specifications and more detailed descriptions: (hook lift chassis) Motor Type Electric motor Asynchronous motor Asynchronous motor Asynchronous motor Loading heights Loading heights (mm) Discharge heights (mm, 10°-35°) Shredding unit hydraulic Dimensions in transport position/working position (conveyor belt 35°) Hook – L x B x H (mm) Drum drive Weight (dependent on equipment) Hook (t) Throughput (dependent on material) Throughput

Open the catalog to page 8

Komptech GmbH Kuhau 37 8130 Frohnleiten, Austria +43 3126 505 - 0 info@komptech.com © 2022 Komptech GmbH. No liability accepted for changes, errors and misprints. Printed on PEFC-certified paper, which was produced in Styria, Austria. Because you need a Because you need to Because you have the Because you always setup that is tailored to adapt your output to choice between new, rental need to keep your your waste stream. your market needs. and used machines. system running.

Open the catalog to page 9All Komptech GmbH catalogs and technical brochures

-

TERMINATOR E-MOBILE

9 Pages

-

TOPTURN X 4500/5000

12 Pages

-

Green

20 Pages

-

Service & Parts

12 Pages

-

BALLISTOR

4 Pages

-

MULTISTAR L3

4 Pages

-

SEPARATION

12 Pages

-

MULTISTAR ONE

4 Pages

-

MOBILE DRUM SCREENS

16 Pages

-

AXTOR

8 Pages

-

CRAMBO

16 Pages

-

GREEN EFFICIENCY

8 Pages

-

MULTISTAR

4 Pages

-

terminator

16 Pages

-

DRUM SCREENS

16 Pages

-

STATIONARY MACHINES

24 Pages

-

MOBILE MACHINES

32 Pages