Catalog excerpts

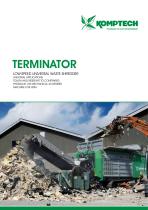

TERMINATOR LOW-SPEED UNIVERSAL WASTE SHREDDER UNIVERSAL APPLICATIONS TOUGH AND RESISTANT TO CONTRARIES HYDRAULIC OR MECHANICAL AS DESIRED MACHINE FOR WISH

Open the catalog to page 1

TERMiNATOR UNIVERSAL HIGHLIGHTS Shreds even the toughest materials Tough and resistant to contraries Different shredding units for a perfect fit with the application Mobile machines with numerous chassis and equipment options Stationary machines with optional hydraulic or mechanical power The processing of waste for materials recycling or energy production usually starts with shredding, to condition the waste cross-spectrum for further process steps. This is exactly what the Terminator is built for. As a low speed single-shaft shredder it can be used on all types of waste. Through...

Open the catalog to page 2

04 Commercial waste special applications Bulky waste, waste wood, mixed construction waste Few shredders have as large a feed hopper as the terminator, which is naturally a great advantage for bulky waste and waste wood. The tough, contrary-resistant U shredding unit has no problems dealing with bulky waste. With the shredding gap open, it can coarsely break up even the toughest materials like railroad ties and iron plates. The aggressive feed of the F shredding unit and programmable reverse cycles keep throughput high with waste wood. These waste streams demand even shredding and long...

Open the catalog to page 3

Inside the machine Engine - mobile machines The Komptech brand stands for quality, reliability and value retention. Accordingly, from the engine to the discharge conveyor, only top-quality components are used in the Terminator. M odern Caterpillar® diesel engines Powerful cooling system for engine and hydraulics Easy access to all maintenance points The power plant of the mobile Terminator is a modern Caterpillar® diesel engine. The complete encapsulation of the engine room reduces noise emissions to a minimum. The hydraulic drum drive with loaddependent speed control develops the maximum...

Open the catalog to page 4

» Load-dependent speed control » S version options: Double drum drive for higher shredding force » Starting and reversing even under load » Easily understandable operating console » Monitoring by on-board computer » Reversing program to adapt to material and for drum self-cleaning » Broad discharge channel with excellent access to the discharge conveyor » High clearance track option: 1 m high discharge channel for problem-free discharge of coarse shred » Folding hopper for easy material feed » Steplessly adjustable discharge conveyor inclination Adjustable counter comb » For adjustment of...

Open the catalog to page 5

SHREDDING UNIT SHRED ANYTHiNG HIGHLIGHTS Extremely large intake area, 2 m wide x 3 m long Three shredding units for a perfect fit with the application U for Universal F for Fine XXF for Extra Fine Variable particle size through cutting gap adjustment Low wear costs thanks to re-usable teeth, with optional armouring Even the toughest kinds of waste don't stand a chance against the Terminator. It gets it all down to the desired particle size. Depending on the shredding unit, material is coarsely broken down or shredded to a defined grain. The hydraulic adjustment of the gap between drum and...

Open the catalog to page 6

02 U (Universal) -for coarse breakup The drum has two spiral rows of triangular teeth, 30 in all. The spiral arrangement ensures proper movement and even shredding. The 16 teeth on the counter comb are a perfect fit for the geometry of the drum teeth. - Ideal for initial breakup - Very contrary-resistant - Triple-use drum teeth - Cutting gap adjustable from 5-80 mm - For bulk waste, municipal waste, white goods, waste wood, railroad ties, mixed construction waste etc. F (Fine) -for a wide range of uses The drum has two spiral rows of left and right cutting rectangular teeth, 16 per row. The...

Open the catalog to page 7

HIGHLIGHTS The right chassis for any application and ground Mobility at the work site through self-propulsion or towing facility Full access to all maintenance points and the shredding chamber Numerous options for more functionality and ease of use TERMiNA MOBILE The mobile Terminator gives you the choice between hook, three-axle trailer or tracked versions. On the hook version, a towing facility provides manoeuvrability at the site. The trailer version has air-cushioned axles and positioning capability for comfortable mobility. The tracked version with two-stage drive and extra-wide treads...

Open the catalog to page 8

Within easy reach More room for discharge With the redesigned engine compartment, all maintenance can now be performed from outside the machine. Easily opened doors give access and fold-out platforms provide safe footing. A special option is available for tracked Terminators - High Clearance. This higher discharge channel (1 m instead of 0.6 m) adds leeway to make sure that coarsely broken and bulky items can clear the machine easily. The overbelt magnet is now mounted in a specially designed, steplessly adjustable holder that gives parallel positioning of the magnet over the discharge...

Open the catalog to page 9

TERMiNATOR DIRECT HIGHLIGHTS Electric drive for high efficiency and minimal maintenance About 20-35 percent lower specific consumption than comparable hydraulic systems Low space requirements: The drive system fits snugly in the machine The same functionality and contrary resistance as the hydraulic versions Exact material fit through intelligent control with two drum speeds Electrically driven stationary machines, with their energy efficiency, low maintenance burden and technical control advantages, are perfect for large plants with long machine running times. Stationary Terminator...

Open the catalog to page 10

HIGHLIGHTS TERMINATOR HYDRAULIC Hydraulic drive for high shredding power and stepless throughput control Separate installation with hydraulic drive: - Protects the drive unit - Saves in-line installation space Numerous options are available for setup, material intake/output, drive and controls The stationary hydraulic Terminator is useful for materials that are difficult to shred and can be expected to require a lot of reversing. Hydraulic drive is also a good choice where frequent changes of materials require constant throughput rate adjustments to accomodate downstream machines, thanks...

Open the catalog to page 11All Komptech GmbH catalogs and technical brochures

-

CRAMBO E-MOBILE

9 Pages

-

TERMINATOR E-MOBILE

9 Pages

-

TOPTURN X 4500/5000

12 Pages

-

Green

20 Pages

-

Service & Parts

12 Pages

-

BALLISTOR

4 Pages

-

MULTISTAR L3

4 Pages

-

SEPARATION

12 Pages

-

MULTISTAR ONE

4 Pages

-

MOBILE DRUM SCREENS

16 Pages

-

AXTOR

8 Pages

-

CRAMBO

16 Pages

-

GREEN EFFICIENCY

8 Pages

-

MULTISTAR

4 Pages

-

DRUM SCREENS

16 Pages

-

STATIONARY MACHINES

24 Pages

-

MOBILE MACHINES

32 Pages