Catalog excerpts

Kongskilde Ploughs OUR MAIN PLOUGH RANGE Kongskilde ploughs Ploughs for all soils, from the experts. Moving agriculture ahead

Open the catalog to page 1

From Överum to Kongskilde For more than 360 years the ÖVERUM factory has led in the industrial production and processing of steel. For the last 165 years, they have been producing ploughs, so they know a thing or two about ploughing! The core competence, then as now, is the finishing of steel. The mould boards are made of carbonized hardened steel, so today Överum possess the most thorough processing of wearing parts on the market. The treatment time is 19 hours. Subsequently, after various intermediate steps the wearing parts are then hardened. The main plough frame is pretreated in a...

Open the catalog to page 2

Which plough for which tractor In your search for a new plough, there are two parameters: tractor power and the number the furrows. Kongskilde ploughs consist of a modular system which means Using our table you can quickly find the appropriate model that best suits your requirements the modules are bolted to the frame, not welded. Kongskilde has continually developed the plough range and technology. The focus was on efficiency, precision and economy. 6 furrow 4 furrow XRWS | XRWT 5 furrow 6 furrow 5 furrow 7 furrow 8 furrow Front Plough FMRT

Open the catalog to page 3

Good reasons for ploughing Among mechanical weed cultivation, the plough has through centuries been acknowledged to be the most reliable machines in cultivations. Threats of herbicide resistant weeds getting more and more abundant is forcing today’s farmer to rearm and again upheld the plough as key strategy for weed control as last resort. The plough has many advantages: it not only breaks through the capillary, but mixes the crop residues and fertilizer perfectly and promotes the release of nutrients through mineralization. Harmful animals such as mice and snails are also combated to an...

Open the catalog to page 4

The angle of the share does matter The fuel consumption and the use of the tractor are highly important for farmers to achieve a low cost cultivation. The Swedish University of Agriculture (SLU) has presented interesting findings on this subject. A comparison of the three most common plough brands was also done by SLU. A 100 hp tractor was used to measure the draft requirement of the four furrow ploughs. Kongskilde AXbody has the lowest draft requirement among its competitors Draft requirement The force to pull a tine as a function of the angle of attack, after Godwin (1974) The angle of...

Open the catalog to page 5

Pflügefollows Form für Profis function The design of our plough bodies The type AX is a turning plough body with an extremely low draft requirement. This body has a universal application in all different types of soil for ploughing depths of 10-28 cm and with working widths of 30 - 55 cm. The type AXP has the same body and properties as AX, only the mould board is made of plastic. Ideal for ploughing in very sticky soils. The type XLD is a turning plough body of low draft requirement, for tractors with wide tyres (710 mm). Excellent turning of the furrows plough depths of 12-30 cm with a...

Open the catalog to page 6

Mucro Steel Kongskilde genuine parts – heat treated for optimum performance Innovative steel handling More than 350 years of experience in steel handling is driving our benchmark for tomorrows innovations. State-of-the-Art processing The mould board blanks are processed for 18 hours in a carbon rich environment with high temperatures and cooled for 4 hours with nitrogen gas. The mouldboards are then heated up for 30 min to bring them into shape. Over 2 hours of reheating with 150° removes all stress out of the board ensuring highest quality. creating a maximum surface hardness with a...

Open the catalog to page 7

Pflüge für Quality forProfis you Discover Quality Kongskilde ploughs are designed to offer farmers quality ploughing results, easy operation and advantageous operational economy. All this is built upon several generations experiences in developing ploughs. This places Kongskilde ploughs in a league of their own. Heavy duty dimensioning and high quality material ensures a long life time! 125 Headstock: Means the dimension of the hollow shaft. Designed for tractors up to 180 hp. Cross shaft Cat. II and III. 150 Headstock: Means the dimension of the hollow shaft. For trouble free ploughing...

Open the catalog to page 8

Flush or reversible points; wear plates for all landsides are available. Heavy duty turn axle and removeable cross shaft is standard Frame alignment cylinder standard from 5 furrows Carbonized and hardened wearing parts Optional hydraulic stone trip applying an individual accumulator for each plough leg All frames are manufactured from 100 % Swedish quality steel

Open the catalog to page 9

High Tech T-Model 80 cm: stongest plough leg of market Frame and Beam Kongskilde ploughs feature frames made out of one piece, without weldings. On the frame, all parts are bolted. The design of the main frame has got precision drilling made by high technological CNC machines for the extensive bolt assembly. Kongskilde has a high strength compared to the weight ratio! Which means that it is possible to use a heat treated Steel with 40% higher strength compared to standard frame tubes. The profile has a high section modulus and can endure high loads. This modularity has many advantages. Worn...

Open the catalog to page 10

Easy Set offers you many advantages for daily use: • Easy operation. The front furrow width and the alignment are adjusted to a basic setting using separate spindles not influencing each other. Easy Set A simple system that ensures correct adjustment of the plough. This means excellent ploughing and lower operating costs. Easy Set automatically adjusts the alignment of the plough as you adjust the front furrow. The system is designed as a parallelogram, where the geometry is calculated in order to adjust the alignment correctly once the basic setting of the plough is • Correctly adjusted...

Open the catalog to page 11

Stone protection Stone release system Shear bolt system This system is most useful in soil with few fixed stones. The design is simple and inexpensive. Ploughs with shear bolts have a lower weight, and the centre of gravity is closer to the tractor. This reduces the lift requirement. The shear bolts are manufac- tured from hard steel and dimensioned to burst at a force of 4.000 kg. All other design in the plough is dimensioned to exceed this force. With the high strength of the shear bolt you can plough non-stop even with smaller obstacles. The hard steel shears with a clean break to make...

Open the catalog to page 12All KONGSKILDE Industries A/S catalogs and technical brochures

-

VIBRO SEEDER 6000

4 Pages

-

1-rotor rakes

8 Pages

-

Rotavator

6 Pages

-

Complete diet mixers

32 Pages

-

NS 1500 - 1900

2 Pages

-

Vibro Compact

4 Pages

-

Tedders

8 Pages

-

Front Terra C

2 Pages

-

SB4000/SB5200

4 Pages

-

Vibro Crop 2017

4 Pages

-

Rotary rakes with 2 rotors

8 Pages

-

Clean cut 2021

20 Pages

-

Trailed forage harvesters 2021

12 Pages

-

VIBRO TILL 2900

8 Pages

-

COMBI JET

8 Pages

-

COMBISEED HT3000S-HT4000S

4 Pages

-

FLEXI DRILL

4 Pages

-

MULTI JET

8 Pages

-

KONGSKILDE FRONT TERRA DISC

2 Pages

-

KONGSKILDE TERRA-D

2 Pages

-

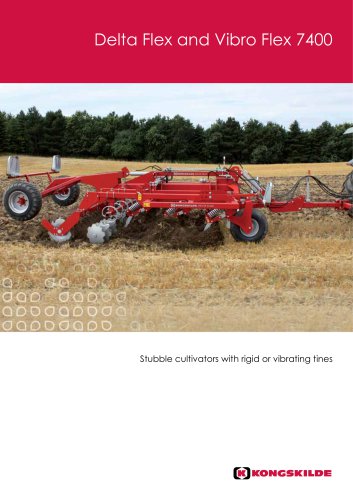

DELTA FLEX

8 Pages

-

VIBRO FLEX 7400

8 Pages

-

VIBRO FLEX FRONT MOUNTED

6 Pages

-

VIBRO TILL 2900 SF

8 Pages

-

VIBRO TILL 8200 SF

12 Pages

-

BETTER FUEL EFFICIENCY

2 Pages

-

ÖVERUM CT-F

2 Pages

-

XLD PLOUGH BODY

5 Pages

-

KONGSKILDE MS-MT

2 Pages

-

VIBRO CROP VCR

2 Pages

-

KDC 8000

4 Pages

-

ASPIRATOR PRE-CLEANERS - KF

8 Pages

-

FAN GUARD

2 Pages

-

PNEUMATIC GRAIN CONVEYING

16 Pages

-

R+ 1610

8 Pages

-

R+ 2 ROTORS

8 Pages

Archived catalogs

-

Trailed forage harvesters 2016

12 Pages

-

Clean cut 2016

20 Pages