Catalog excerpts

Kongskilde ploughs Semi-mounted reversible ploughs Moving agriculture ahead

Open the catalog to page 1

The range of Kongskilde ploughs includes ploughs up to ten furrows adapted for large farms. The ploughs combine great strenght and easy handling with perfect ploughing features. Kongskilde semi–mounted ploughs are Perfect ploughing easy to manoeuvre thanks to hydraulics. Kongskilde semi-mounted ploughs are developed for hard work on big farms. The ploughs are available with a working width up to 5 meters. Eventhough the capacity is enourmous we have not compromised when it comes to the ploughing features. The result is a plough which is easy to set to correct depth and width. The big wagon...

Open the catalog to page 2

Strong design Kongskilde SRS, SRT SRS and SRT models are the lightest semimounted reversible ploughs from Kongskilde. The ploughs are designed for tractors up to 132 kW (180 hp). The furrow width is easy to adjust between 35, 40, 45 cm (14”, 16”, 18”). Main frame dimension is 150x150 mm. The design and stability of the plough makes it easy to handle. Supporting wheel The large wheel 400/55x22.5 (1000x400mm) on the plough gives low rolling resistance, exact working depth and efficient weight transfer. When reversing on the headlands it is possible to steer the wheel in order to get the...

Open the catalog to page 3

A new generation Kongskilde HSRWT, HSRWS A new generation of semi mounted ploughs with hydraulic adjustable furrow width The new semi mounted plough from Kongskilde is developed for the larger farms were focus is at high capacity and low cost. Kongskilde HSRWT/S is available in three sizes, 6-8 bodies, and designed for tractors up to 270kW (370 hp). HSRWT/S can handle the toughest conditions thanks to the strong design and the clever position of joints for adjusting furrow width which gives low stress. Beamhouses: The beamhouses on HSRWT/S are based on the same strong ones as used on the...

Open the catalog to page 4

Clever details Stone release The stone release system protects the plough from damages. On the Kongskilde ploughs the stone trip safety system is top class. When the plough hits a firm obstacle the disc coulter follows the body. For extra protection of the disc coulter there is a spring loaded version. Fully automatic non-stop system Kongskilde semi – mounted reversible ploughs is equipped with automatic gashydraulic safety system, which is separately adjustable for each component. The hydraulic stone protection system works perfectly under almost all different ploughing conditions. The...

Open the catalog to page 5

Wagon plough Even ploughingdepth When ploughing the front part works similar to a semi– mounted plough. For the rear part a special joint is designed, this joint makes it possible for the rear part to follow the ground even in undulating fields. The ploughing depth is adjusted with the three–point linkage on the tractor, the cylinders on the wagon and the depth wheel 10,0/80–12 (Ø 710x264mm) on the rear part. THSRT is the biggest and strongest of all Kongskilde ploughs. THSRT is available from 7 to 10 furrows and is dimensioned for tractors up to 258 kW (350 hp). The plough consists of two...

Open the catalog to page 6

Packerarm for model SRS/SRT. Packerarm for model HSRS/HSRT and THSRT. Disc coulters are available plain, notched or rippled, spring loaded or fixed. Knife coulter and coverboard. Furrow widener. Semi-mounted reversible ploughs Plough type SRS Wagon plough Stone release system: S = Shearbolt, T = Hydraulic stone release R = Reversible plough S = Semi-mounted H = Heavier model T = Wagon plough

Open the catalog to page 7

The design engineers work in a three dimensional computer environment. Every detail is designed as a solid prepared to make movement and strength calculations on. This makes it possible to test every function and movement in the computer before constructing the first prototype. Directly linked to the design computer there is a numerically controlled mill which produces a model of the detail. The information is transferred to the mill which produces the exact tools used for hot bending and hardening of the parts. Despite all modern techniques, of course all new products are rigorously tested...

Open the catalog to page 8All KONGSKILDE Industries A/S catalogs and technical brochures

-

VIBRO SEEDER 6000

4 Pages

-

1-rotor rakes

8 Pages

-

Rotavator

6 Pages

-

Kongskilde Ploughs

28 Pages

-

Complete diet mixers

32 Pages

-

NS 1500 - 1900

2 Pages

-

Vibro Compact

4 Pages

-

Tedders

8 Pages

-

Front Terra C

2 Pages

-

SB4000/SB5200

4 Pages

-

Vibro Crop 2017

4 Pages

-

Rotary rakes with 2 rotors

8 Pages

-

Clean cut 2021

20 Pages

-

Trailed forage harvesters 2021

12 Pages

-

VIBRO TILL 2900

8 Pages

-

COMBI JET

8 Pages

-

COMBISEED HT3000S-HT4000S

4 Pages

-

FLEXI DRILL

4 Pages

-

MULTI JET

8 Pages

-

KONGSKILDE FRONT TERRA DISC

2 Pages

-

KONGSKILDE TERRA-D

2 Pages

-

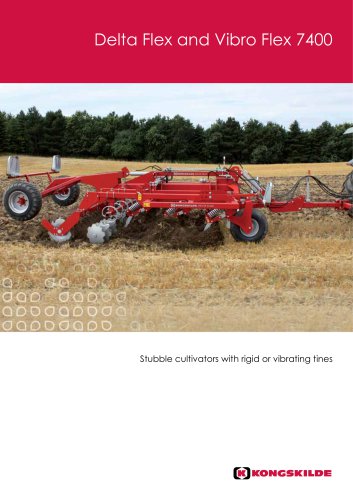

DELTA FLEX

8 Pages

-

VIBRO FLEX 7400

8 Pages

-

VIBRO FLEX FRONT MOUNTED

6 Pages

-

VIBRO TILL 2900 SF

8 Pages

-

VIBRO TILL 8200 SF

12 Pages

-

BETTER FUEL EFFICIENCY

2 Pages

-

ÖVERUM CT-F

2 Pages

-

XLD PLOUGH BODY

5 Pages

-

KONGSKILDE MS-MT

2 Pages

-

VIBRO CROP VCR

2 Pages

-

KDC 8000

4 Pages

-

ASPIRATOR PRE-CLEANERS - KF

8 Pages

-

FAN GUARD

2 Pages

-

PNEUMATIC GRAIN CONVEYING

16 Pages

-

R+ 1610

8 Pages

-

R+ 2 ROTORS

8 Pages

Archived catalogs

-

Trailed forage harvesters 2016

12 Pages

-

Clean cut 2016

20 Pages