Catalog excerpts

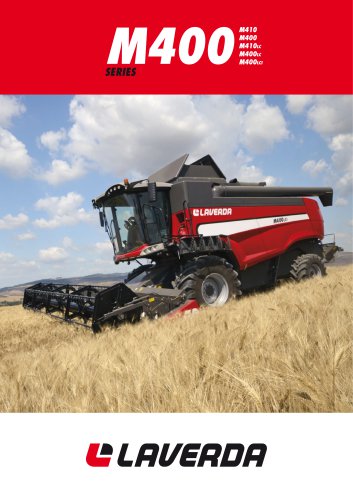

AGILE, DEPENDABLE, SMART: DISCOVER IT THROUGH THE CAB SKYLINECAB CUTTINGHEADER Free Flow and Power Flow cutting headers, for easier and more efficient harvesting of every crop type, with the hydrostatically driven pickup reel and the new TST automatic system for a constant cutting height. GREEN-ENGINES Emission level stage IV EGR and SCR technology Agco Power engines are designed for low fuel consumption, maximum economy, long life expectancy and reduced emissions. PFR/MCS SIEVES HCD WORKING IN SPECIALIZED AGRICULTURE FOR MORE THAN 140 YEARS The skills and technological culture aquired...

Open the catalog to page 2

POWER FLOW VERSATILITY TAKES TO THE FIELD KNIFE The exclusive Schumacher system guarantees a higher cutting strength, precision, and a 1.220 rpm working speed even on green or damp crops. The strong and reliable gear box vibrates less therefore, less wear on the cutting header. The blades of the knife are double supported, constantly sharp and self cleaning, therefore more difficult crops like oil seed rape, peas and rye are tackled with ease. REEL The hydraulic reel can be regulated to 3 different positions, high enough to reach taller crops and low enough to allow the reel tines to reach...

Open the catalog to page 3

FREE FLOW EVERY SINGLE COMPONENT IMPROVES THE PERFORMANCE HYDROSTATICALLY DRIVEN PICKUP REEL It is equipped with newly designed tines, anti-clogging blades (Schumacher system) and simplified drives. This combination of components improves balance and the efficiency of the pickup reel on laid crops and is practically zero maintenance. HEADER/MACHINE COUPLING The cutting headers are hitched by a centralized multiple coupling system for all electric and hydraulic controls. This makes hitching a quick, simple and precise operation. TST LARGE-DIAMETER AUGER Thanks to a large-diameter auger with...

Open the catalog to page 4

A FLOWING PRODUCT CONTINUOUS AND REGULAR CROP FEEDING, TO EXPLOIT THE GREAT CAPACITY OF THE THRESHING ELEMENTS

Open the catalog to page 5

WIDE CROP ELEVATOR: HIGH PRODUCTIVITY AND BETTER VISIBILITY FROM THE CAB Laverda knows that ideal threshing requires good preparation and consistent crop feeding. The long crop elevator, with large intake, is designed to improve the performance of the machine with a greater capacity, a smoother crop flow and the possibility of coupling with larger headers and offers the operator better visibility from the cab. Header lift capacity is improved with the lift cylinders lifting capacity up to 2.600 kg. THRESHING THAT KNOWS HOW TO HANDLE ANY TYPE OF HARVEST The drum, with a 600 mm diameter and a...

Open the catalog to page 6

V y y{, / '/ '* *>Urn 1 ./.}/■ t / *, ZvjfilMV- \

Open the catalog to page 7

MAXIMUM EFFICIENCY AS A STANDARD STRAW CHOPPER AND CHAFF SPREADER A PERFECT ADDITION The powerful fan with a differential flow rate has two air inlets at the sides and one at the top. In addition to cleaning the grain, these features guarantee superior performance and low fuel consumption in all crop conditions. Laverda’s long straw walker system achieves further active separation thanks to the exclusive design of the walker pans and steep steps. The M 410 and M 400 have a 9.000 litre grain tank, while hillside models have a designed 8.600 litre tank. All models have a unloading rate of 105...

Open the catalog to page 8

SKYLINE CAB WORK WITH THE TOP OF COMFORT AND TECHNOLOGY

Open the catalog to page 9

SPATIAL INTERIOR AND A FULL VISUAL FIELD DESIGNED AROUND THE OPERATOR The Skyline Cab has been developed by Laverda engineers to create a well designed ergonomic control center for operating ease and efficiency, while at the same time providing a spatial and extra comfortable working environment. The cab interior is functional and practical while its light grey interior has a feel and look of quality, perfect for high technology machinery. A COMFORTABLE WORKPLACE Easy access is guaranteed by a telescopic ladder and wide cab entrance. With an optimal seating position in the air-suspended...

Open the catalog to page 10

POWERGRIP ARMREST The clearly laid out and well designed right-hand armrest is the central operating unit with which operators can make all settings and adjustments. The operators can place their arm comfortably on the adjustable armrest with immediate access to the toggle engagement switches. POWERGRIP LEVER The position of the user-friendly Powergrip lever makes it a perfect hand rest for the entire day, offering intuitive use, ergonomic shape and angle tilt. The most important cutting functions and the integrated grain unloading on/off controls are managed by the conveniently placed...

Open the catalog to page 11

TECHTOUCH TERMINAL TOTAL CONTROL WITH ONLY ONE TOUCH Laverda understands the requirement for a multi-functional Hi-Tec terminal in a combine, however it's also very important that the technology is easy to use. Therefore, Laverda introduces the TechTouch Terminal, a new generation of terminals, which has been developed for the operation needs of the combine harvester. It can conveniently be used with both touch screen technology or the navigation keys and rotary control. The 10.4” TechTouch Terminal guarantees detailed machine monitoring and control with its intuitive, multi-lingual menu...

Open the catalog to page 12

SIMPLE TECHNOLOGY ADDITIONS GUIDANCE SIGNAL SET UP SCREENENGAGEMENT INFORMATION LOGS Using the latest technology - the AUTO-GUIDE xls option can steer you through to higher performance optimising the field layout - easily set from the TechTouch Terminal AUtO-GUIDE xls can offer accuracy down to 5 cm. Automation leaves the operator to focus on getting the best from the whole machine. A button on the Powergrip Lever reactivates the system when turning on the headland. AUTO-GUIDE XLS WORKFLOW SCREEN The TechTouch Terminal can provide performance information through the resettable trip...

Open the catalog to page 13

NEW LEVELLING CONCEPT A LEVELING SYSTEM THAT OFFERS "ELEVATED" TECHNOLOGY TO MOVE WITH AGILITY AND SAFETY, WHERE OTHERS STOP

Open the catalog to page 14

The M 410 LC, M 400 LC and M 400 LCI models rise above the group because of Laverda's exclusive and patented, lateral action levelling system, based on 2 movements: machine body levelling, and table levelling. The lateral levelling system uses two reinforced joints that, through electrohydraulics, provide a lateral adjustment of the machine on different gradients of the terrain. This enables a transverse levelling of up to 20% and makes it possible to work well on European hillsides, assuring high performance in total comfort and with the maximum safety. EXCLUSIVE LEVELLING AND...

Open the catalog to page 15All Laverda catalogs and technical brochures

-

SERIE M300

19 Pages