Catalog excerpts

Emission level stage IV SCR technology Agco Power engines designed for low fuel consumption, maximum economy, long life expectancy and reduced emissions. PROLINECAB Free Flow and Power Flow cutting headers, for easier and more efficient harvesting of every crop type, with the hydrostatically driven pickup reel and the new TST automatic system for a constant cutting height. PFR/MCS WORKING IN SPECIALIZED AGRICULTURE FOR MORE THAN 140 YEARS The skills and technological culture aquired duing more than a century of history, make Laverda one of the most qualified manufacturers of combine...

Open the catalog to page 2

POWER FLOW VERSATILITY TAKES TO THE FIELD KNIFE The exclusive Schumacher system guarantees a higher cutting strength, precision, and a 1.220 rpm working speed even on green or damp crops. The strong and reliable gear box vibrates less therefore, less wear on the cutting header. The blades of the knife are double supported, constantly sharp and self cleaning, therefore more difficult crops like oil seed rape, peas and rye are tackled with ease. REEL The hydraulic reel can be regulated to 3 different positions, high enough to reach taller crops and low enough to allow the reel tines to reach...

Open the catalog to page 3

FREE FLOW EVERY SINGLE COMPONENT IMPROVES THE PERFORMANCE HYDROSTATICALLY DRIVEN PICKUP REEL It is equipped with newly designed tines, anti-clogging blades (Schumacher system) and simplified drives. This combination of components improves balance and the efficiency of the pickup reel on laid crops and is practically zero maintenance. HEADER/MACHINE COUPLING The cutting headers are hitched by a centralized multiple coupling system for all electric and hydraulic controls. This makes hitching a quick, simple and precise operation. TST LARGE-DIAMETER AUGER Thanks to a large-diameter auger with...

Open the catalog to page 4

CROP ELEVATOR, THE SOLUTION THAT ELEVATES PRODUCTIVITY PFR WHEN EFFICIENCY IS THE OUTCOME OF REGULARITY The PFR, Power Feed Roller system, exclusive to the M 310 MCS and M 300 MCS models, based on a roller fitted with retracting fingers at the entrance of the elevator channel, is another solution to ensure the continuous and even flow of crop from the cutting header to the threshing apparatus. The advantages are plentiful: more regular threshing, constant levels of combine performance, lower power requirements, reduced fuel consumption and longer lasting drives. The benefits are obvious...

Open the catalog to page 5

V- ^Mrtfrvb i ; -f, [•*! »' ■ ■ ^ v . J' - ,- , :■ • \ «viv^- '■ r*“ *r ^*.■ jTriM* $£&£■&fyti.lpM ,**£*#.**..., ' - * -.jv- ° - Vrt . f* T f.T»- •“ ^-T u * • ->77’

Open the catalog to page 6

LAVERDA HAS DEVELOPED SEVERAL SOLUTIONS TO GUARANTEE MAXIMUM EFFECTIVENESS FOR CROP HARVESTING OPERATIONS AND SEPARATION The drum, with a 600 mm diameter and a width of 1,340 mm, for the machines with 5 straw walkers and a width of 1,600 mm for the 6 straw walker machines, are equipped with eight rasp bars and eight ballast bars. This ensures that the crop is separated in an optimal way, while maintaining the quality of the straw and grain. The ballast bars give the cylinder a fly wheel effect, reducing the space between one bar and another; making the threshing process extremely regular...

Open the catalog to page 7

STRAW CHOPPER THE MOST EXTENSIVE STANDARD EQUIPMENT FOR EXCEPTIONAL CLEANING AND INTEGRITY Laverda’s long straw walker system achieves further active separation thanks to the exclusive design of the walker pans and steep steps. Manufactured in the Breganze factory, Laverda’s straw chopper is a perfect match to all the M 300 Series combines and it is available as optional. It is activated by a hydraulic mechanism and can be used for all crops. If the straw is to be baled, Laverda’s straw chopper can be deactivated by simply moving the deflector which disengages it. Available with a 64-bladed...

Open the catalog to page 8

The cab comes with a host of features you would expect in an operator environment of this quality: fully automatic air conditioning including heating; air suspension seat; electrically adjustable heated mirrors; instructor seat with cooler (optional) and storage box; excellent sound insulation means you work in quiet comfort; safe and easy to use cab steps. PROLINE CAB YOUR CONTROL CENTRE DESIGNED FOR YOU TO GET THE BEST FROM YOUR MACHINE DAY OR NIGHT Fundamental elements of good cab design include space, comfort and visibility. The new Proline cab offers all of these, ensuring complete...

Open the catalog to page 10

HAND SHAPED CONTROLS FOR EASY OPERATION KEYPAD POWERGRIPLEVER REEL LIFT/LOWER REEL FORE/AFT AUTOMATIC STOP CUTTING HEADER UP/DOWN CUTTING HEADER LEVEL LEFT/RIGHT UNLOADING ENGAGEMENT UNLOADING TUBE OPEN/CLOSE The new control interface for the operator falls naturally to hand – the PowerGrip multifunction lever sits on top of the armrest which houses all the switches for the commonly used controls. As the propulsion lever does not need to slide it makes operation far less tiring than conventional set-ups. POWERGRIP ARMREST ENGINE SPEED SETTING THRESHER ENGAGEMENT CUTTING HEADER ENGAGEMENT...

Open the catalog to page 11

SIMPLE TO READ AND USE The easy-to-read colour touch screen Automated crop settings - seve-can be adjusted for each operator, which ral variations of crop settings can choices for what should be displayed. be added within the menu on the TechTouch 2 terminal, which when Clear uncluttered display makes the selected will alter the combine autojob of interpreting the information matically. very easy - warnings are shown clearly as a priority. The new TechTouch 2 Terminal is the control centre for all key performance operations, it has a touch screen, and you can use the unique safety...

Open the catalog to page 12

ADVANCED COMPONENTS, EXCLUSIVE TECHNOLOGIES M 300 Series Rice combines have been created to meet quality rice cultivation requirements even in countries where the climate allows more than 2 harvests per year. The Free Flow and Power Flow cutting headers with TST (the automatic system that follows the ground and achieves intelligent cutting), the feeder with retractable fingers (PFR) able to even out the most intertwined rice crop and feed the threshing components in a perfect manner. Reliable machines that ensure quality harvesting for any variety of rice. M 300 SERIES RICE Free Flow / Power...

Open the catalog to page 13All Laverda catalogs and technical brochures

-

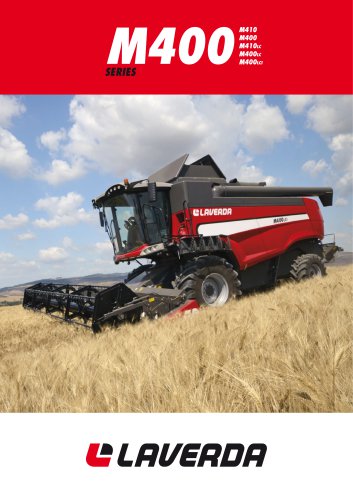

M400

21 Pages