Catalog excerpts

Read this manual before starting to use this equipment. This manual contains safety instructions. Warning! Failure to follow the instructions can cause serious injury.

Open the catalog to page 1

Big Mill System Welcome to Logosol! We are pleased that you have placed your trust in us by choosing the Timberjig, and we promise to do our best to satisfy your expectations. Logosol began production of our flagship product, the Logosol Sawmill, in 1988. Since then we have delivered more than 15,000 sawmills to satisfied customers around the world. The first Timberjig was delivered in 1990. So far, every owner of a Timberjig we have talked to has been delighted with this simple, but functional, equipment. Many customers have, however, looked for a product that is a little more outfitted...

Open the catalog to page 3

Information about this manual Whenever this symbol appears, a tip follows that will simplify or improve the results. LOGOSOL is constantly developing its products. For that reason we reserve the right to make changes in the design and construction of our products. Text: Mattias Byström Translation: Anna Olsgren Byström Illustrations: Mattias Byström First edition: 2003-04-08 Latest revision: 2009-09-03 Copyright 2003 LOGOSOL, Härnösand, Sweden Manual, Article No: 9999-000-9999 Timberjig directions used in this manua

Open the catalog to page 4

Table of Contents Subject: Concerning: Page: Preparations Wooden Aids 11 Work Site Wooden Aids 12 Sawing Wooden Aids 12 Assembly Big Mill BASIC 16 Work Site Big Mill BASIC 18 Guide Rail Supports Big Mill BASIC 18 Height Setting Big Mill BASIC 19 Sawing Big Mill BASIC 20 Guide Rail Extension Big Mill BASIC 24 Sawing Long Logs Big Mill BASIC 25 Safety Instructions Big Mill LSG 26 Guide Rails Supports ext Big Mill PRO 29 Double Guide Rails Big Mill PRO 30 Oversized Logs Big Mill PRO 31 Demands for Sawing Precision 33 Upgrading: Logosol Sawmill 39

Open the catalog to page 5

Safety Instructions, 2 pages "WARNING!" Pay extra attention when this symbol appears in the text. For your own safety, do not begin working with the Timberjig before having read and understood the entire manual. Also read the manual and safety instruction for the chainsaw you are using. Incorrect use of the Timberjig can cause life-threatening injuries. Cutting tools: Never place your hands or tools past the scale bail while the chain saw is running. Use protective gloves when operating the Timberjig. Risk of cutting injuries when handling the saw chain. The cutting equipment can be hot...

Open the catalog to page 6

When using a petrol-driven chainsaw: Fire danger! Turn the motor off before filling with petrol. Petrol is extremely flammable. Burn injuries can be life-threatening. If you spill fuel, clean the area immediately. If you get fuel on your clothing, change at once. Tighten the petrol tank cover to minimize the risk of its vibrating loose during operation. Never saw with the throttle in locked position, Always control the throttle manually while sawing. Safety check before starting the chainsaw. O Always check that: ...the guide rail holders and the guide rail are assembled correctly. .all...

Open the catalog to page 7

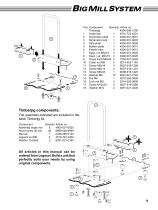

(A) Fit two plastic rollers to the underside of the side plate. The rollers are adjustable inwards and outwards. Position them so that their edges are in line with the outer edge of the side plate. (2x M6x16 screws, 2x M6 washers, 2x M6x18 special nuts.) (B) Fit the inner plastic rollers in the bottom plate tracks. These rollers should not rotate. (2x M6x14 screws, 2x M6 washers, 2x M6x12 special nuts.) (C) Insert the star knobs through the hexagonal holes in the dimension lock and screw on the collar nuts, with the collar towards the dimension lock, approximately 20 turns. (2x star knobs...

Open the catalog to page 8

Pos. Component Quantity Article no. Timberjig 4900-000-1000 Timberjig components: The quantities indicated are included in the basic Timberjig kit. 1 Scale bail 2 Dimension plate 4 Side plate 5 Bottom plate 6 Plastic roller 7 Spec. nut M6x12 8 Spec. nut M6x18 Component Assembly angle iron Wood screw 20 mm Manual Logosol nut M8 Washer 11x28x2 All articles in this manual can be ordered from Logosol. Build a unit that perfectly suits your needs by using original components.

Open the catalog to page 9

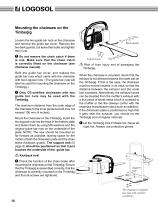

Mounting the chainsaw on the Timberjig Loosen the two guide bar nuts on the chainsaw and remove the guide bar cover. Remove the two bark guards, but leave their bolts and tighten their nuts. Do not remove the chain catch if there is one. Make sure that the chain catch is correctly fitted on the chainsaw (see chainsaw manual). Refit the guide bar cover, and replace the guide bar nuts which came with the chainsaw with two Logosol nuts. (The guide bar nuts will later be used for mounting the chainsaw on the Timberjig.) Only CE-certified chainsaws with two guide bar nuts may be used with the...

Open the catalog to page 10

2. Preparations - Timberjig Wooden Aids Building a straight, wooden guide rail. Make a straight guide rail out of two, preferably planed, boards, ca 22 mm thick (1 inch) and 120-150 mm wide (5-6 inches). The guide rail should be 40 cm longer than the logs you plan to saw. Do not make the guide rail longer than necessary. Use angle irons and wood glue to obtain a right angle and a strong bond. It is vital that the corner the Timberjig will run on is exactly 90°. Sawing with the Timberjig requires certain preparations. The idea behind the Timberjig design was to create a fully functioning...

Open the catalog to page 11

The Work Site - Wooden Aids Prepare your work site on a clear and level ground. The easiest way to support a log that you are about to saw is to place it across two parallel, smooth, and level logs. The height of your support logs should not exceed 50 cm (20 inches). Q If logs are used as a work bench, remember to keep them from rolling by using e.g. wedges. Make sure you do not saw on an upward slope. It is better that the log bed is somewhat higher on the side you start sawing on, in order to ensure that you saw slightly downwards. Screw a 30 mm (1 1/8 inch) wood block on both ends of the...

Open the catalog to page 12

7. Fasten the log securely, paying special attention that it will not move when the Timberjig is mounted on the guide rail. This is a prerequisite for smooth and safe sawing. One method is to screw a board into the log end, making sure that it makes contact with the ground. Tip risk. Check that the log is fastened well, o Use at least two wood screws, 4x80 mm (1/4”x3 1/8”) or larger. An alternative is a log clamp (art. no. 4900-001-0400) for fastening the log. Q Do not start your chainsaw until you have read and understood both the chainsaw and the Timberjig manual. Q Always perform the...

Open the catalog to page 13All Logosol AB catalogs and technical brochures

-

B1001 HYDRAULIC

64 Pages

-

Big Mill System

52 Pages

-

B751 PRO BAND SAWMILL

92 Pages

-

F2+ CHAIN SAWMILL

52 Pages

-

Product Catalog 2022

68 Pages

-

F2 Chain sawmill

16 Pages

-

Multi-Head Planer/Moulders

40 Pages

-

product_catalogue

96 Pages

-

moulding_catalogue

92 Pages

-

b1001

92 Pages