Catalog excerpts

Kombi-Parallelogram (Kombi-PP) ^'irit ^^^^ Inter-row Fertilizer Band- and Underleaf Sprayer Track Loosener Guiding Systems Frames and Types of Mounting Potato Care Husbandry Cutting Discs for Strawberries Rolling Cultivator

Open the catalog to page 3

Good reasons • Higher aeration and root growth through cracked crusts • Improved water absorption due to less erosion • Increased micro-organism activity mobilizes nutrients • Improved mineralization • Improved root growth by loose and moist soil • Less growth problems and leave damage cause by the use of herbicides (e.g. necrosis on beet leaves) ■ Removal of chemical resistant weeds or secondary growth ■ Suppression of weather based late weed growth ■ Cost savings due to reduce herbicide application 100% for organic farming, up to 70% for usual farming What is important when hoeing? • Slim...

Open the catalog to page 4

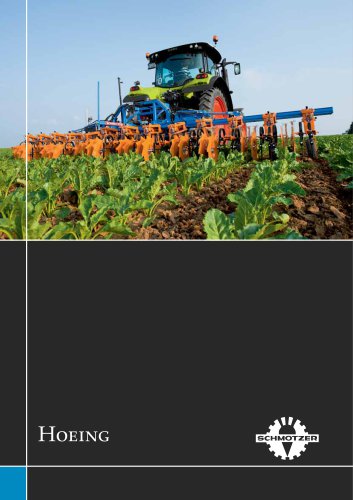

Advantages of today's hoeing • Enhanced ground performance due to working widths up to 24 metres • Driving speed up to 15 km/h with opto-electronic steering and vibro-blades • Tandem-hoes: perform two drilling widths in one working step • Reduced cost for machinery • Reduced cost for herbicides • 8 times increased durability based on slide bearings made of high tech synthetic material (iglidur ©) in combination with a hardened steel bushing. Schmotzer uses this in all hinges. • Hoeing between the rows using fingers and/or blades curry-comb failed for cereal cultures due to harsh crus-...

Open the catalog to page 5

Universal parallelogram for many applications Applicable for all row widths from 25 cm Applicable for taller plants and working widths up to 24 metres (Kombi-PP) is used universally for row widths ranging from The Kombi-PP is also the base unit for the Schmotzer loosen- Tools can easily be changed and combined to vary the working The round or indented protec- tion disc is fixed to the paral- easily and quickly for each type bearing press wheel is adjust- able by a spindle and secures a well-balanced hoeing depth even on wide working areas. The structural change towards larger farming areas...

Open the catalog to page 6

Hoe 20 x 45 cm with double frame, vertically foldable (see page 15 machine in folded position)

Open the catalog to page 7

■ The leading technology for all cultures ■ Applicable for row widths from 25 to 60cm based on its high quality and long life cycle. It is well known adjustment variety that allow highest performance even in the soil, 1 to 3 blades (fixed or vibro type) can be mounted in various positions. The depth is controlled by a farmflex roller The blade entry can be adapted in five levels by means of a dou- ble-spring load. The equipment with two or three vibro-springs and different kinds of protec- tion shields is anytime possible. Available standard specifica- The A share (duckfoot blade) in...

Open the catalog to page 8

starting from left: duckfoot share, L blade straight leg, L blade cropped leg, round protection disc HS62 and indented disc HSZ Rigid tines are situated in strong tine holders. The working without blocking. Straight legs (no weed catch- er) and large sliding scale of the blades ensure a good flow even if high amounts of weed or stones are present. Strong and heavy parallelo- working depth of blades. blades are possible for work- 7 A double-spring load with 5 positions allows penetration 9 Guiding discs with self cleaning farmflex wheels (di- link plates and adjustable 11 High stability of...

Open the catalog to page 9

A must have for organic farming Very well suitable for corn and specialized cultivation Applicable for row widths ranging from 16 cm to 45 cm and work- Exact soil adaptation based on single guided hoeing tools EPP long with vibro blade the combination of tines with a front Independent of the cutting width and number of rows, each tine is working A passing through of weed as well as a moving of clods onto the rows is avoided. Weed is cut completely and The spring load is adjustable at differ- ent levels and therefore ensures per- fect adaptation to the ground. Mount- ing of short and long...

Open the catalog to page 10

Disc ridger, share ridger with gauge, spring mounted share ridger, rotable share ridger Potato Care Husbandry Schmotzer offers two specifi- cations of share ridgers. Type 62 (for row widths from the disc ridger (for row widths The Schmotzer disc ridg- the soils tends to clods. They height. There special shaped bottom edge breaks the soil be- The share tip with a good grip in combination with a baffle plate at the leg allows a good shaped moldboards ensure an easy use without damaging the plants even if the rows are already covered. For sandy, marshy or easy crumbling soils the disc ridg-...

Open the catalog to page 11

Schmotzer Accessories Inter-row Fertilizer Requirements for an exact deposition of fertilizer - even if minimum quan- tities are used - are speed dependent dosing cylinders and a slip-free gear. The central driven dosing cylinders of the Schmotzer inter-row fertilizers rotate within a funnel shaped outlet mounted on the fertilizer container. This construction ensures a constant and complete depletion even in hill side situations and allows an exact dosage for different composition of Filling filters are integrated into the covers of the large volume granule boxes to prevent clogging with...

Open the catalog to page 12

Band and Underleaf Sprayer The Schmotzer band sprayer tanks are available with volumes of 300, mounting parts for drilling and hoe- The band spraying system are equipped with diaphragm nozzles. For beets, maize and potatoes the ma- chine can be equipped with nozzles of type 8002 E and bayonet (BV) caps. The underleaf spraying system is also equipped with diaphragm-nozzles. For beets, maize and potatoes un- derleaf nozzles of type UB 8502 and bayonet (BV) caps are necessary. As a standalone solution the spraying parallelograms are equipped with a press wheel (280 mm in diameter) and a clod...

Open the catalog to page 13

Schmotzer Accessories The following guiding systems are available to control a rear-mounted Guiding discs Two self-guided spring-loaded discs work the best at a depth of 8 cm. The hoeing machine itself is carried by the straight-on drive of the guiding discs is secured by adjustment screws. For working widths of 6 m or more the guiding discs are replaced by gui- ding wheels of type AV 7 (7.00 x 12). AVI Precision Control without hyd- For smaller working widths and light machines (e.g. cultivators for cereals) the mechanical AVI steering is ideal. ding on 3 stainless steel shafts. This...

Open the catalog to page 14All Maschinenfabrik SCHMOTZER GmbH catalogs and technical brochures

-

Precision Seeding

16 Pages